Large-caliber aspheric surface primary mirror detection device and method

A detection device and aspheric technology, applied in measurement devices, optical devices, instruments, etc., can solve problems such as difficulty in accurate measurement, and achieve the effects of easy operation, lower detection costs, and balanced performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] In order to make the objectives, technical solutions, and advantages of the present invention clearer, the following further describes the present invention in detail in conjunction with specific embodiments and with reference to the accompanying drawings.

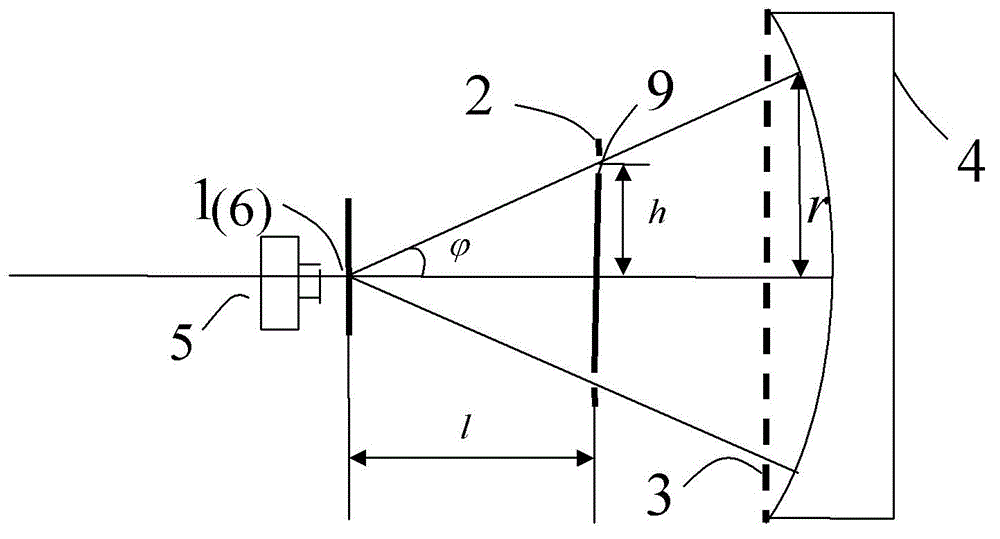

[0038] Such as figure 1 Shown is a large-aperture aspheric primary mirror detection device. The device includes: a point light source 1, a baffle 2, a ruler 3, a measured aspheric primary mirror 4, a CCD detector 5, and a filament 6. Among them:

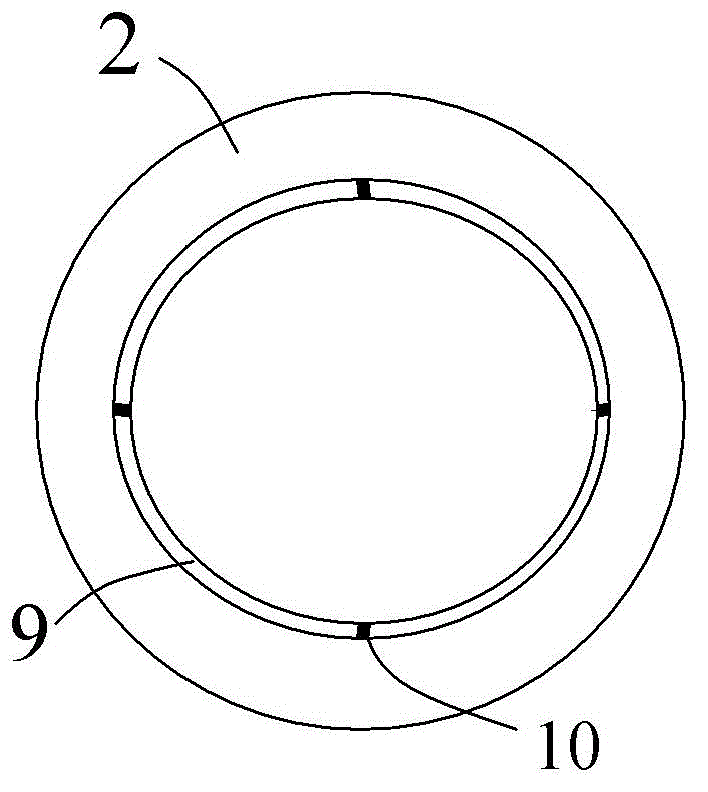

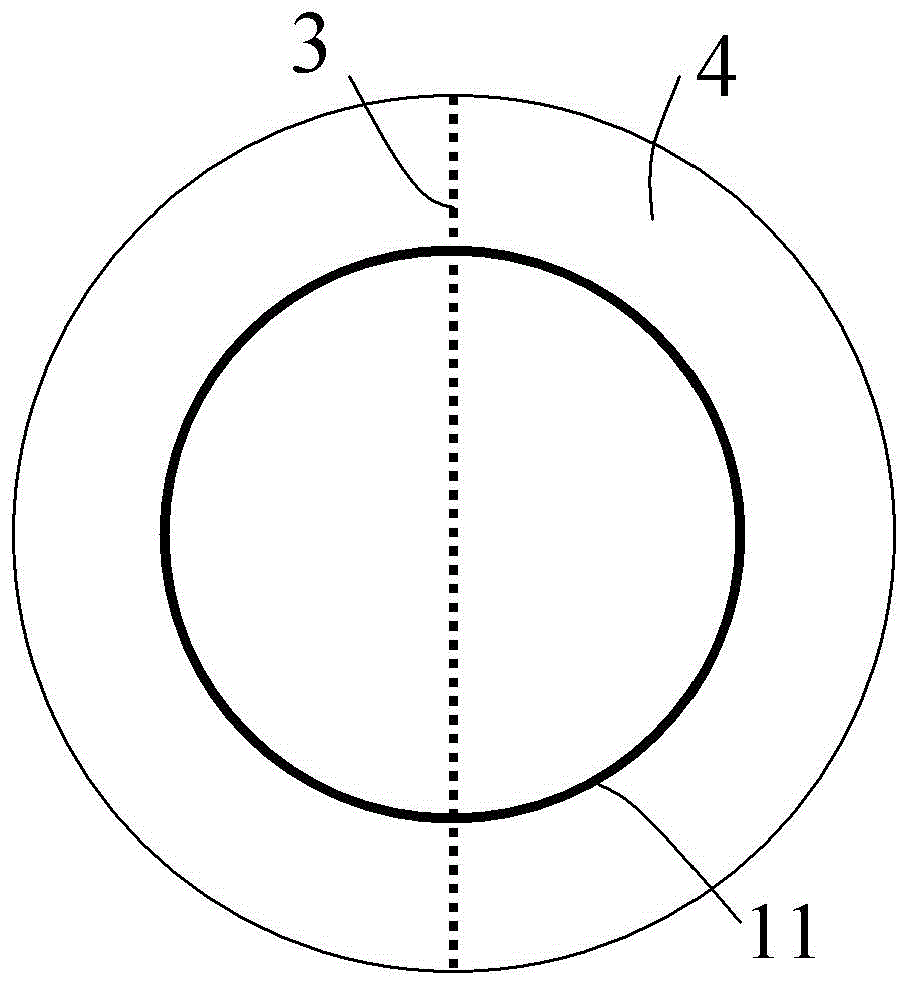

[0039] Place the CCD detector 5, the point light source 1, the filament 6, the baffle 2, the ruler 3, and the measured aspheric main mirror 4 in sequence on the optical axis of the main aspheric mirror 4, where: the ruler 3 is tight Attached to the measured aspheric main mirror 4, the baffle 2 has a circular slit 9 on the body, the point light source 1 emits a spherical wave, and the circular slit 9 on the baffle 2 illuminates the measured aspheric main mirror 4 Above, reflecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com