Image sensor and forming method thereof

An image sensor and device technology, applied in the field of image sensing, can solve problems such as high cost, difficult process control, complex image sensor forming process, etc., and achieve the effects of saving process steps, improving image sensing ability, and increasing the amount of light

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

[0043] The first embodiment of the present invention provides a method for forming an image sensor, please refer to Figure 5 to Figure 9 , is a schematic cross-sectional structure diagram of the formation process of the image sensor according to the first embodiment of the present invention.

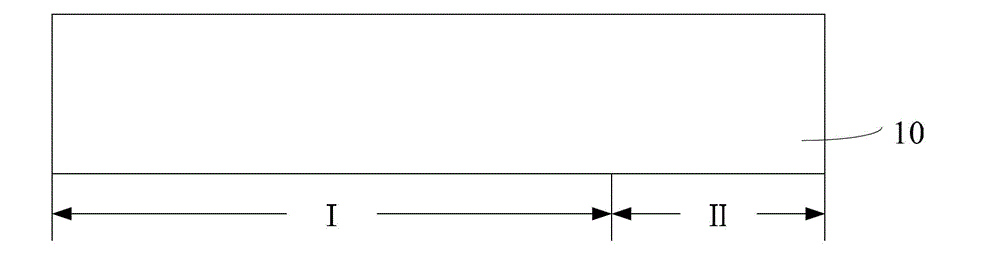

[0044] Specifically, please refer to Figure 5 , providing a semiconductor substrate 100, and the semiconductor substrate 100 includes a pixel array region I and a peripheral device region II.

[0045] The semiconductor substrate 100 is a silicon substrate, a germanium substrate, a silicon carbide substrate, a silicon germanium substrate, a silicon-on-insulator substrate, or the like. The semiconductor substrate 100 is doped with P-type or N-type ions. In this embodiment, the semiconductor substrate 100 includes a heavily doped P-type silicon substrate 101 and a lightly doped P-type silicon epitaxial layer 102 located on the surface of the P-type silicon substrate 101 .

[0046] The ...

no. 2 example

[0075] The second embodiment of the present invention also provides a method for forming an image sensor, please refer to Figure 10 ~ Figure 15 , is a schematic cross-sectional structure diagram of the formation process of the image sensor according to the second embodiment of the present invention.

[0076] Specifically, please refer to Figure 10 , providing a semiconductor substrate 200, and the semiconductor substrate 200 includes a pixel array region I and a peripheral device region II. The semiconductor base 200 includes a heavily doped P-type silicon substrate 201 and a lightly doped P-type silicon epitaxial layer 202 on the surface of the P-type silicon substrate 201 .

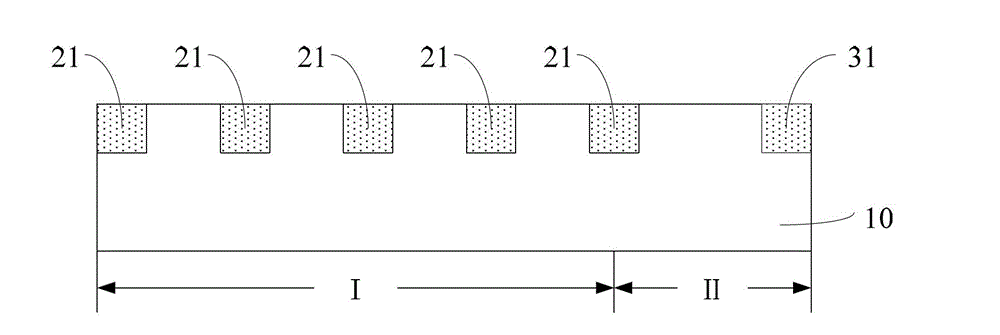

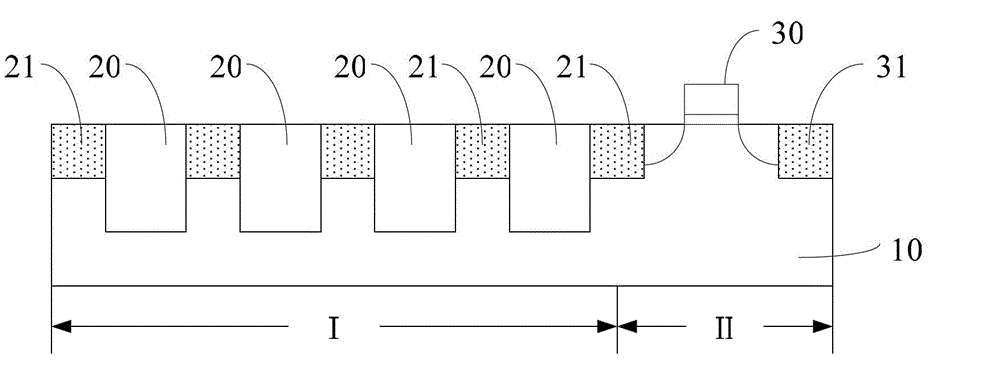

[0077] Please refer to Figure 11 , forming a third mask layer 210 on the surface of the semiconductor substrate 200, and the third mask layer 210 exposes the surface of the semiconductor substrate 200 corresponding to the first shallow trench isolation structure and the second shallow trench isolat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com