Advection sedimentation/immersion type ultrafiltration integrated water treatment device

A water treatment device and advection sedimentation technology, which is applied in the direction of flocculation/sedimentation water/sewage treatment, osmosis/dialysis water/sewage treatment, filtration circuit, etc., can solve the problems of large floor area and long process flow, and achieve saving operation Energy consumption, avoidance of disturbances, effects of extended chemical cleaning cycles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

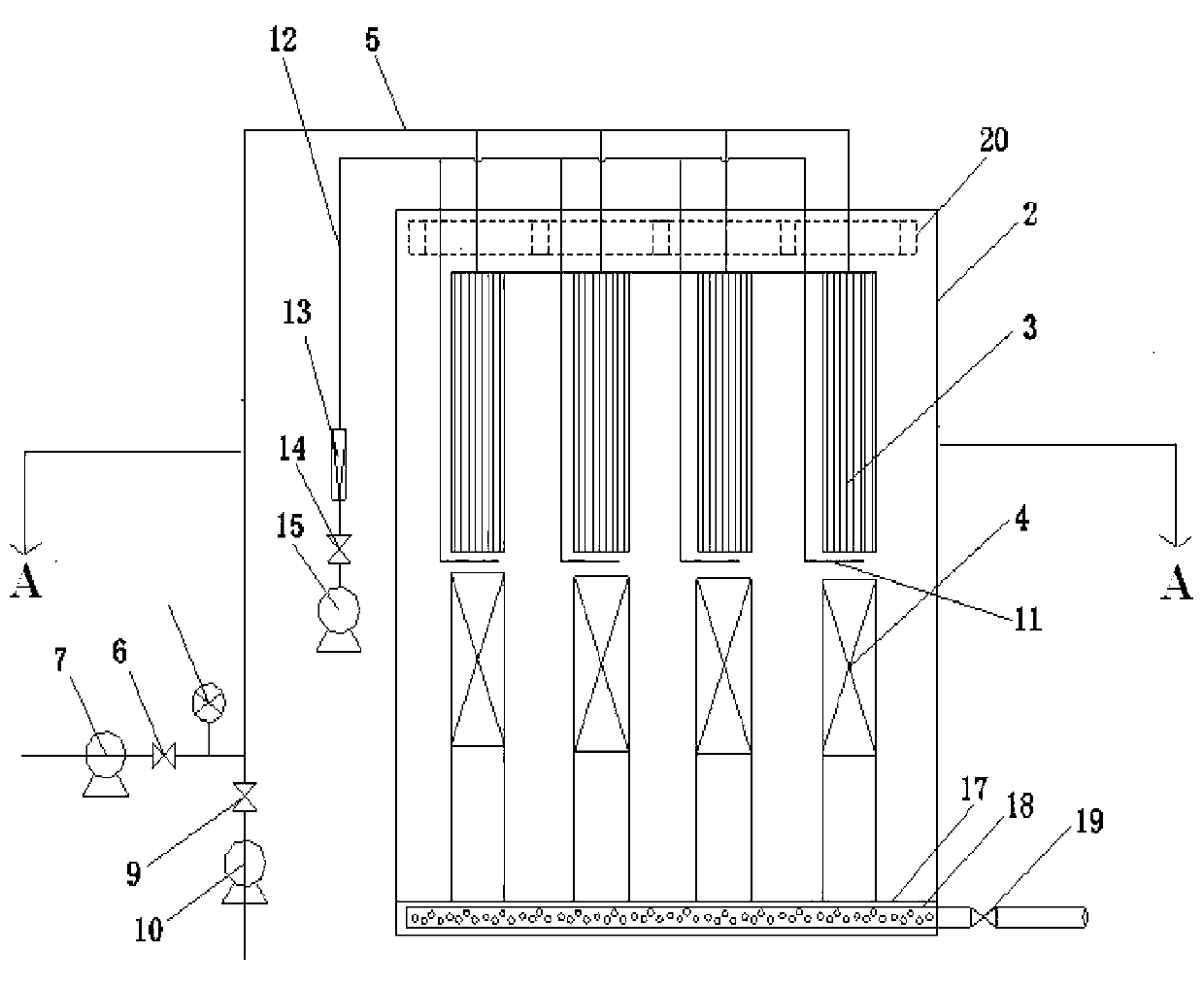

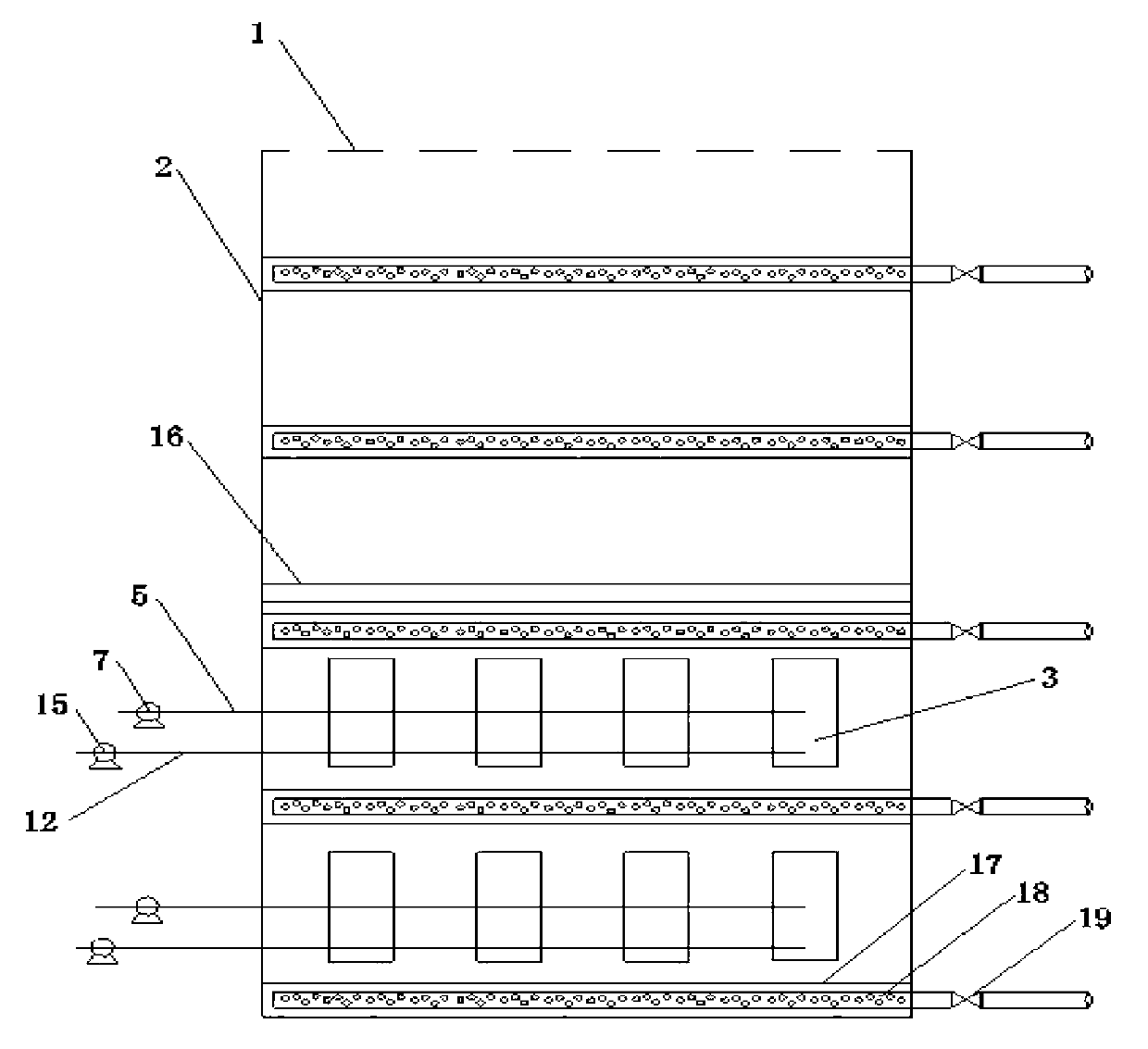

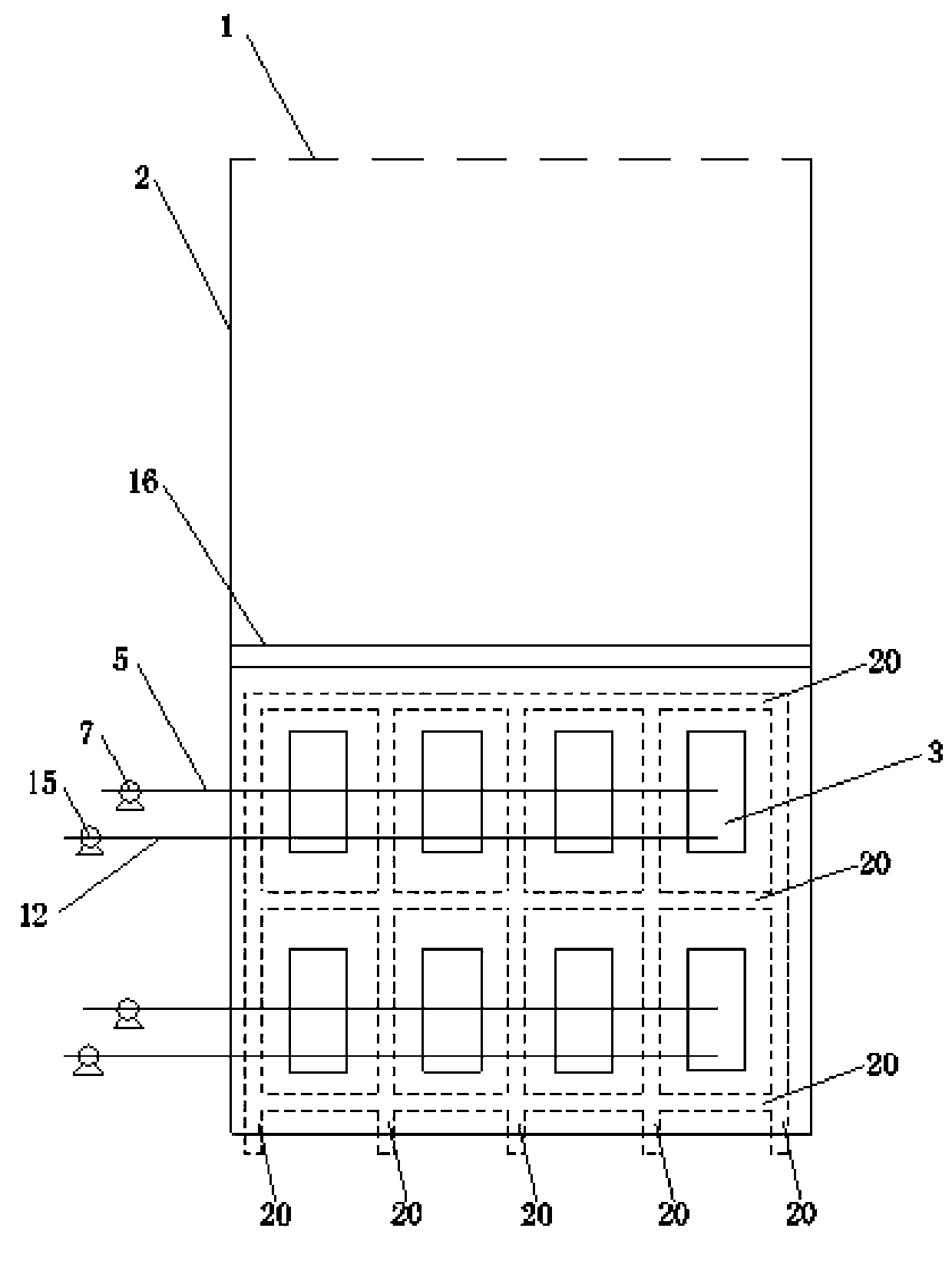

[0019] Specific Embodiment 1: An advection sedimentation / submerged ultrafiltration integrated water treatment device in this embodiment includes an advection sedimentation tank 2, a plurality of submerged ultrafiltration membrane modules 3, a plurality of membrane module holders 4, an ultrafiltration out Water pipe 5, ultrafiltration water outlet valve 6, ultrafiltration suction pump 7, online vacuum pressure sensor device 8, multiple bubble diffusion devices 11, aeration pipe 12, gas flow meter 13, aeration valve 14, aeration pump 15 , a plurality of mud collection tanks 17, a plurality of perforated mud discharge pipes 18, a plurality of mud discharge valves 19 and a plurality of zigzag backwash overflow weirs 20;

[0020] The membrane module holder 4 is arranged at the bottom of the advection sedimentation tank 2, the submerged ultrafiltration membrane module 3 is arranged on the membrane module holder 4, and one end of the ultrafiltration outlet pipe 5 is connected to a plu...

specific Embodiment approach 2

[0031] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the material used in the submerged ultrafiltration membrane module 3 is one of polyvinyl chloride, polyvinylidene fluoride, polysulfone or polyethersulfone , each substance is constructed as a hollow fiber structure with a pore size of 0.01 μm to 0.1 μm. Others are the same as the first embodiment.

specific Embodiment approach 3

[0032] Embodiment 3: This embodiment differs from Embodiment 1 or Embodiment 2 in that: the height of the membrane module holder 4 is 1.0m-2.0m, and the submerged ultrafiltration membrane module 3 is located above the advection sedimentation tank. Others are the same as those in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com