Swelling pressure forming and manufacturing method of zirconium corrugated pipe

A technology of expansion and compression molding and production methods, which is applied in the direction of manufacturing tools, furnace types, heat treatment equipment, etc., can solve the problems of low quality of bellows expansion, uneven material extension, and uneven force on materials, so as to reduce the sensitivity of impurities performance, optimization of bulging quality, and uniform elongation of the material

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

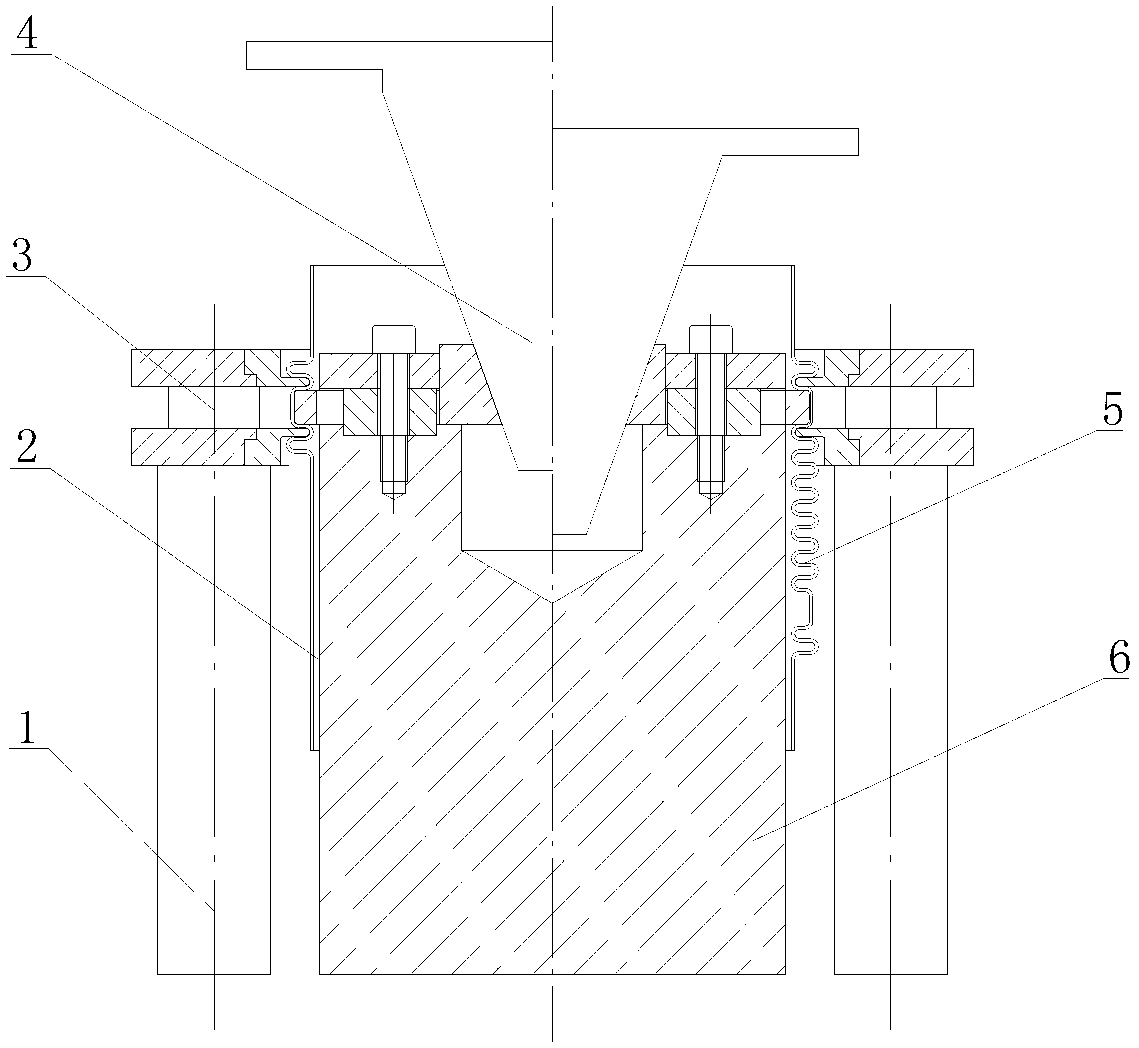

[0016] The specific embodiments of the present invention will be described below in conjunction with the accompanying drawings.

[0017] figure 1 It is a structural schematic diagram of the manufacturing process of zirconium bellows expansion and compression molding. The welding quality of the tube blank before the bellows is formed is particularly important, which will directly affect the expansion and compression forming quality of the zirconium material bellows. The zirconium material is very sensitive to impurities, so the cleaning of the groove and both sides of the groove before welding Oil pollution is particularly important, and the interval between cleaning and welding should not exceed 4 hours, otherwise, it should be cleaned again. Use mechanical methods to remove the surface oxide film at the welding groove and 50mm on both sides, and clean the 75mm range on both sides of the groove with acetone or ethanol. Automatic argon arc welding is adopted, and the purity of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com