Automobile wheel hub machining method

A processing method and technology of automobile wheels, which are applied in the field of automobile parts processing, can solve the problems of low production efficiency, long manufacturing time of aluminum alloy automobile wheels, and high manufacturing costs, and achieve the effect of improving tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] In order to better understand the technical content of the present invention, specific embodiments are given together with the attached drawings for description as follows.

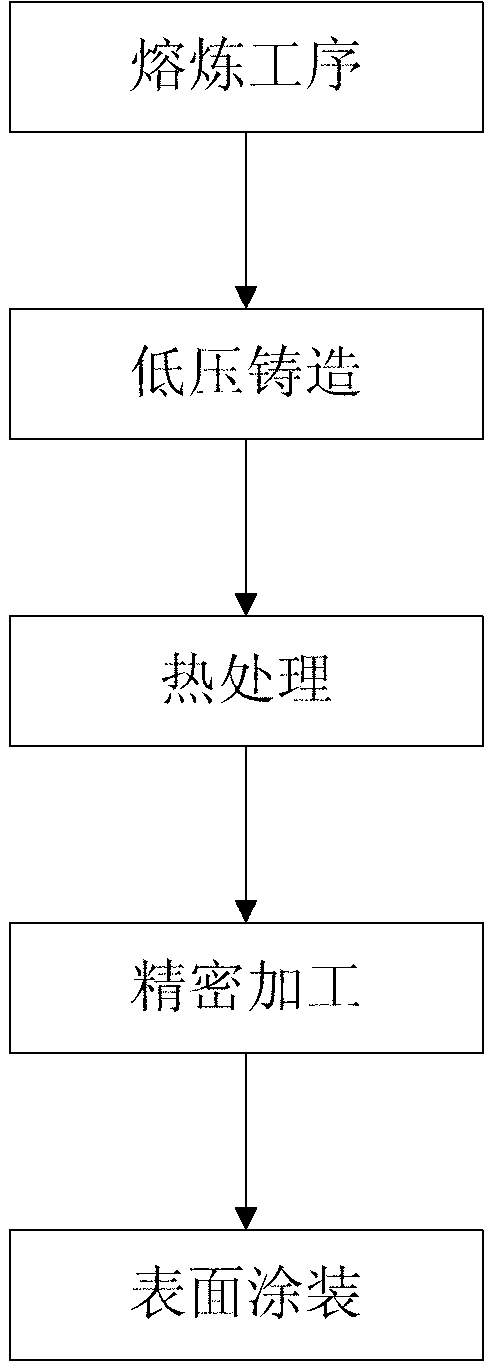

[0012] Such as figure 1 As shown, according to a preferred embodiment of the present invention, a method for processing an automobile wheel includes the following steps: melting process, low pressure casting, heat treatment, precision machining and surface coating. The "content" in this example is the mass percentage.

[0013] In the aforementioned smelting process, metal silicon is added when the temperature of the aluminum liquid rises to 760°C, and electromagnetically stirred for 25 to 30 minutes, wherein the content of metal silicon is between 6.5% and 7.5%, in order to improve the fluidity of the aluminum liquid, and the casting is heat treated magnesium silicide Mg 2 Si, in order to improve the strength index of the product.

[0014] When the molten aluminum comes out of the furnace, add A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com