Preparation method of hydrophilic SiO2 aerogel

A hydrophilic and aerogel technology, applied in chemical instruments and methods, inorganic chemistry, non-metallic elements, etc., can solve problems such as cumbersome process, achieve the effects of expanding application, reducing production costs, and reducing environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

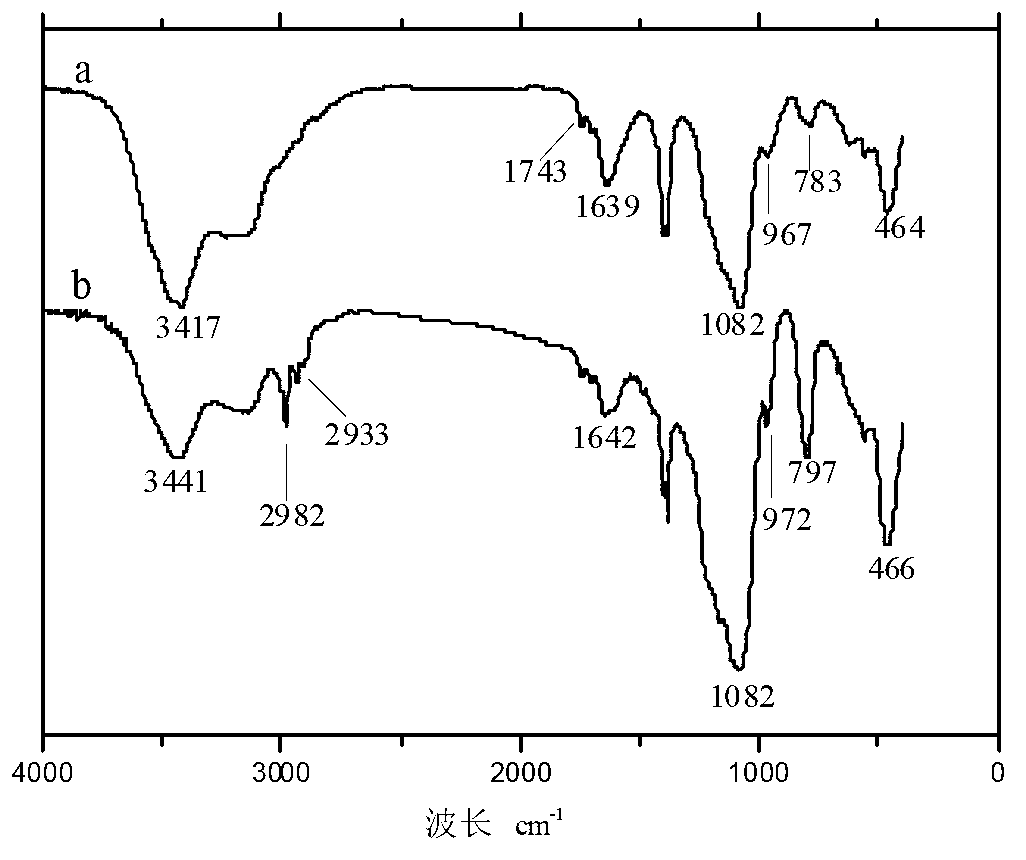

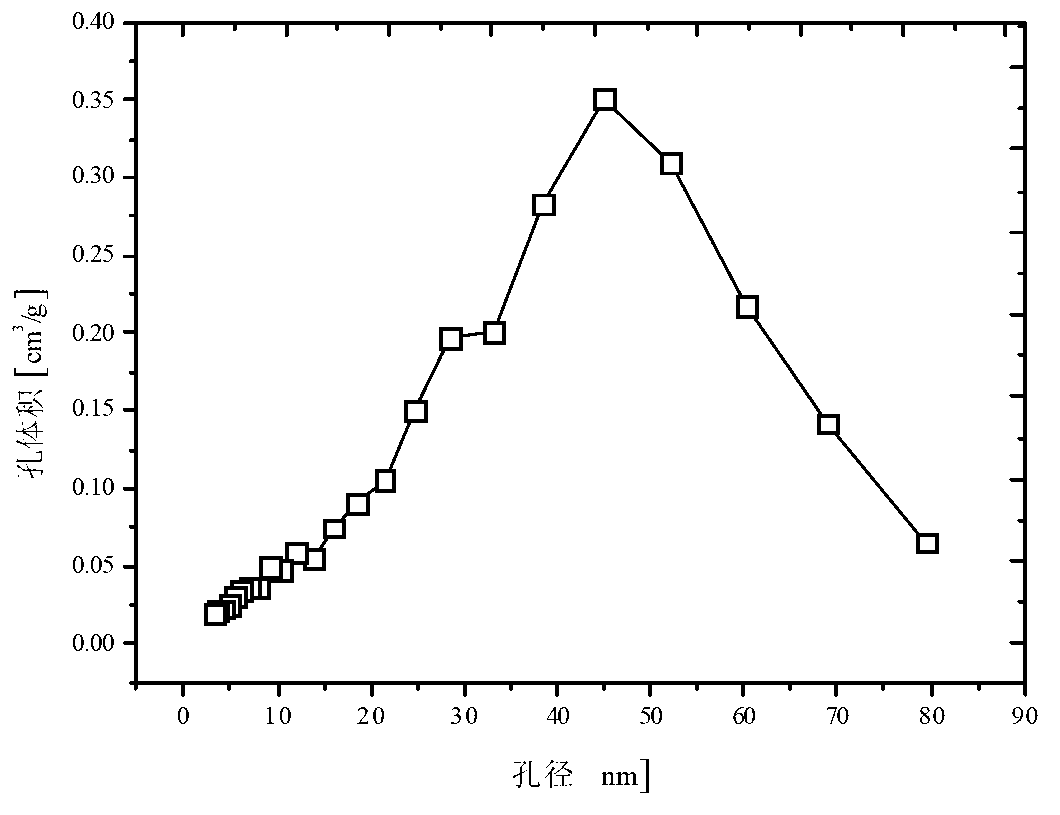

Method used

Image

Examples

example 2

[0034] Mix 25ml orthomethyl silicate (TMOS) with 110ml formic acid (C 2 h 4 o 2 ) after mixing evenly, add 6ml of deionized water at room temperature, stir at a stirring rate of 100 rpm for 3 hours, and use a 35% ammonia solution (NH 3 ·H 2 O) Adjust the pH of the solution to 6.5, seal and let stand for 40 minutes to form SiO 2 wet gel. The prepared SiO 2 After the wet gel was left at room temperature for 6 hours, formic acid solution was added (C 2 h 4 o 2 ) to completely immerse the wet gel, and age at room temperature for 18 days, during which time the aging solution is changed every two days. After aging, use CO 2 In the supercritical drying method, formic acid is first selected to completely immerse the wet gel, and 10MPa of CO is introduced. 2 , at 25°C with a gas release rate of 8L / min for 6h; then raise the temperature to 70°C, and then 2 At the same time, the gas is replaced at a rate of 8L / min for 15h; finally, the CO is released at a rate of 4L / min. 2 Re...

example 3

[0037] Mix 25ml orthomethyl silicate (TMOS) with 95ml acetic acid (C 2 h 4 o 2 ) after mixing evenly, add 9ml of deionized water at room temperature and stir for 4 hours at a stirring rate of 300 rpm, and use a 45% ammonia solution (NH 3 ·H 2 O) Adjust the pH of the solution to 7, seal and let stand for 60 minutes to form SiO 2 wet gel. The prepared SiO 2 After the wet gel was left at room temperature for 10 h, acetic acid solution was added (C 2 h 4 o 2 ) to completely immerse the wet gel, and age at room temperature for 20 days, and replace the aging solution every three days. After aging, use CO 2 In the supercritical drying method, first, acetic acid is selected to completely immerse the wet gel, and 15MPa of CO is introduced. 2 , at 30°C for 2 hours at a gas release rate of 10L / min; then raise the temperature to 80°C, and then 2 Next, replace the gas at a rate of 10L / min for 10h; 2 Release to the same pressure as the outside atmosphere, turn off the power, coo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water absorption | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com