Internal circulation reaction device for sunshine catalytic oxidation and membrane separation three-phase fluidized bed

A three-phase fluidized bed, photocatalytic reaction technology, applied in the field of reaction devices, can solve the problems of unsuitability for scale, commercial promotion and application, reduced treatment effect, difficult separation and recovery, etc., and achieves high mass transfer efficiency and light energy. Utilization rate, easy operation and maintenance, and the effect of increasing the amount of wastewater treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

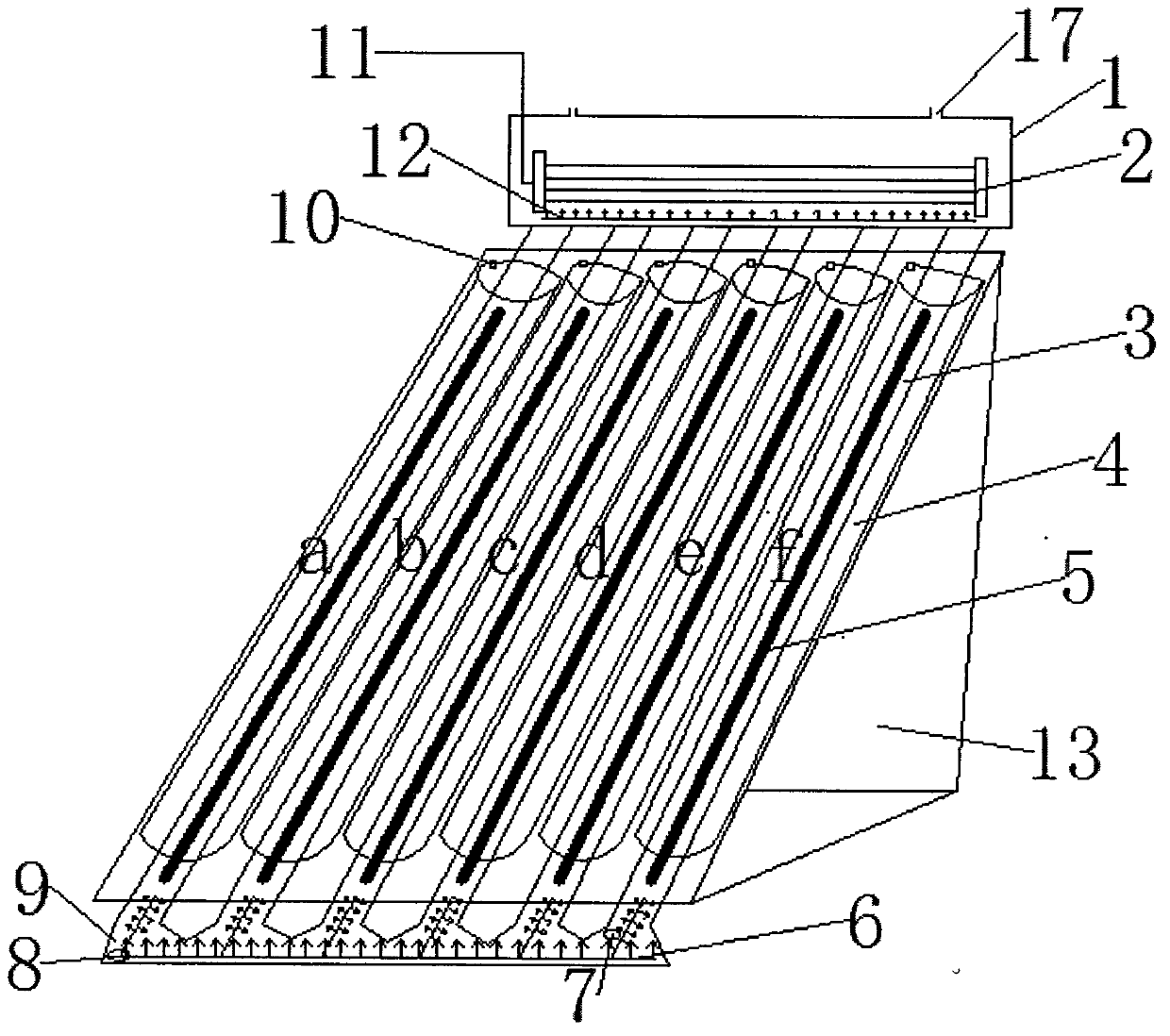

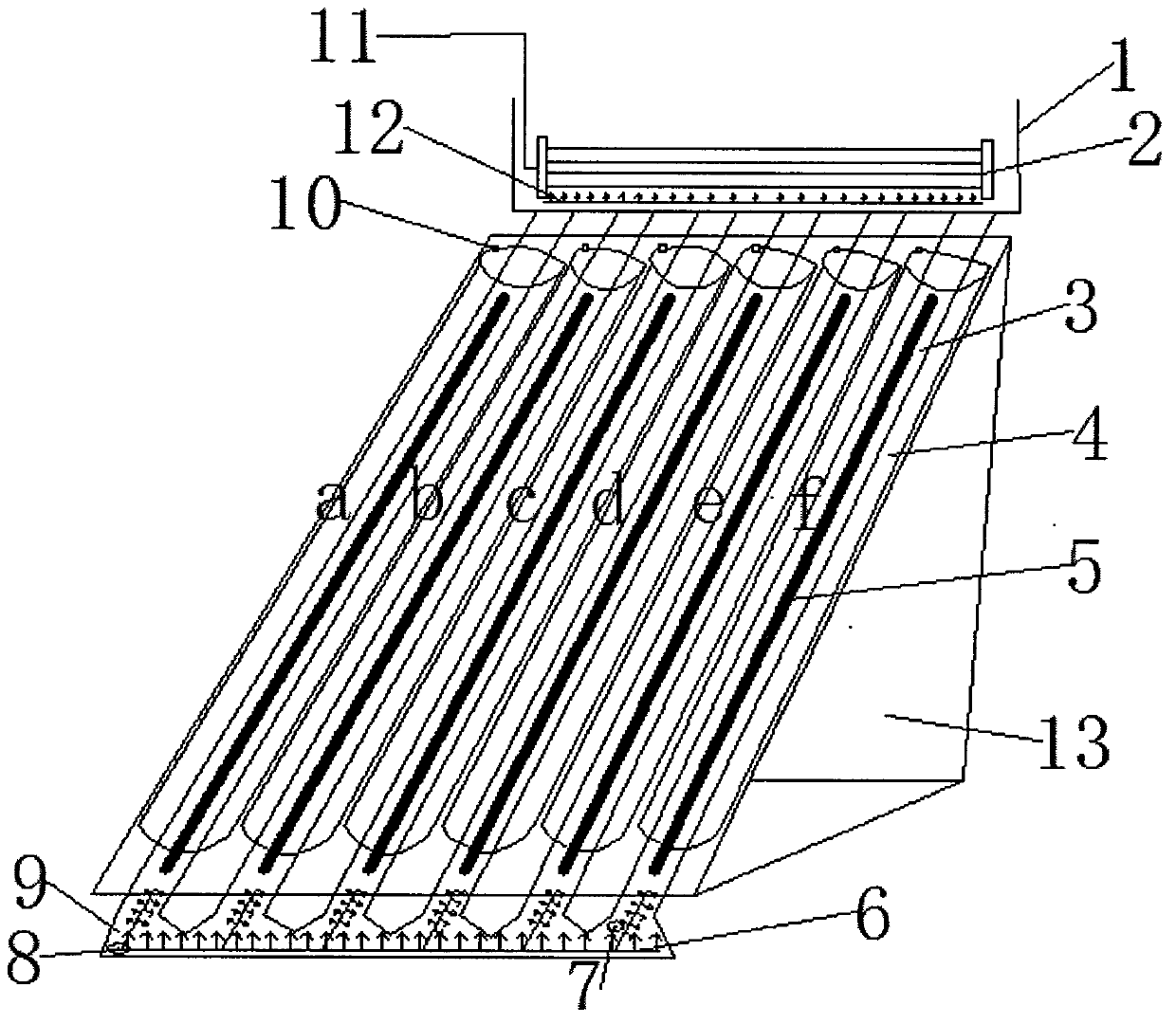

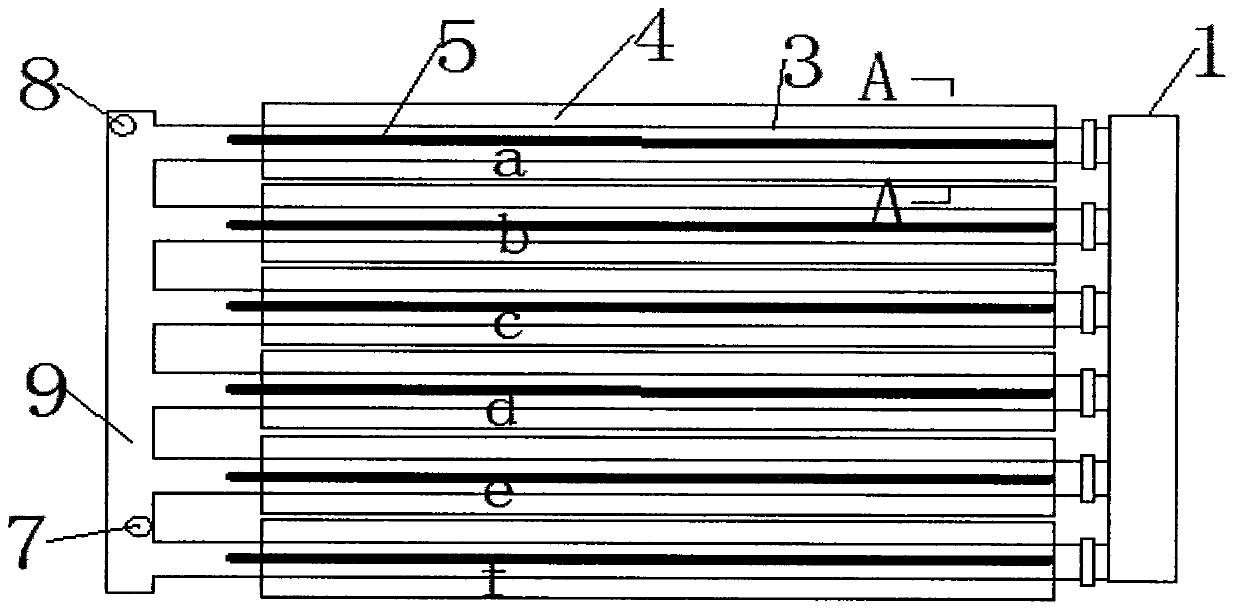

[0040] As shown in the accompanying drawings of the description, the solar photocatalytic oxidation-membrane separation three-phase fluidized bed internal circulation reaction device of the present invention includes a photocatalytic reaction zone and a membrane separation zone, and the photocatalytic reaction zone includes a lighting system, a tubular Reactor 3 and lower water tank 9; Wherein daylighting system comprises daylighting plate 4 and solar tracking device 10, and wherein said daylighting plate 4 then both can be truncated compound paraboloid daylighting plate, also can be solar energy gathering plate, And the described truncated compound parabolic daylighting panel or the solar energy concentrating panel 4 is arranged on the rotating shaft controlled by the sunlight automatic tracking device 10 according to the requirement; the des...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com