Method for decorating domestic ceramic underglaze color

A ceramic glaze and daily-use technology, applied in the field of ceramics, can solve the problems of being unsuitable for assembly line operations and batch production, low production and processing efficiency, and high raw material loss, achieving strong promotion and application value, strong practicability, and low raw material loss little effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

[0081] Implementation Case 1: Red Heart Pattern

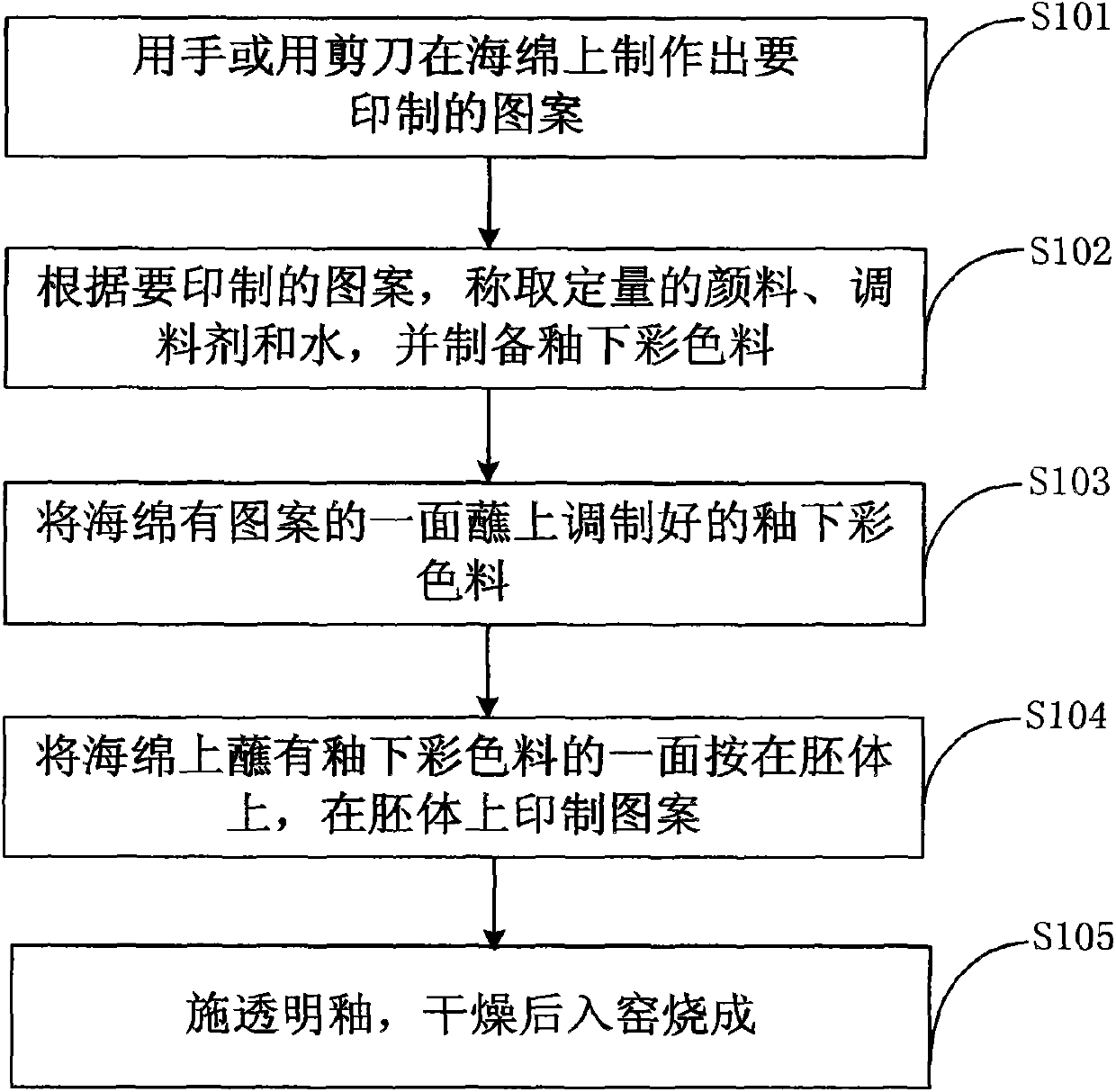

[0082] like figure 1 As shown, first, make a sponge pattern: use a wooden board about 3cm thick to process it into a heart shape, then use glue to stick a thin sponge about 3cm thick and larger in area than the wooden board on the wooden board, and place the excess sponge along the outline of the wooden board Cut off and smooth the surrounding contours;

[0083] Then, prepare the underglaze color material: first weigh 700 grams of wrapped red material, 200 grams of glaze, and 100 grams of green sheet, put them into a 1.5kg ball mill jar, material: ball: water = 1:2:0.6, ball mill 24-48 Hours, until all pass through a million-hole sieve. After that, add about 0.3% seasoning agent, and adjust to the required viscosity with water for later use;

[0084] Then, dip in the coloring material: put a sponge of the same size as the container in a flat container with a caliber larger than the pattern, use a pen to dip the prepared colo...

Embodiment example 2

[0087] Implementation Case 2: Patterns like camouflage uniforms

[0088] like figure 1 As shown, first, make a sponge pattern: when decorating the entire surface (or part) of cups and bowls, use a sponge about 3cm thick and about 4cm in size, and pull it piece by piece by hand on one side to form a relatively uniform honeycomb;

[0089] Then, prepare the underglaze color material: weigh 700 grams of malachite green (blue) color material, 100 grams of green sheet, 100 grams of limestone, and 100 grams of kaolin, put them in a 1.5kg ball mill jar, material: ball: water = 1:2 : 0.6, ball milled for 24 to 48 hours until all passed through a million-hole sieve. After that, add about 0.3% seasoning agent, and adjust to the required viscosity with water for later use;

[0090] Then, dip in the coloring material: put a sponge of the same size as the container in a flat container with a caliber larger than the pattern, use a pen to dip the prepared coloring material and apply it eve...

Embodiment example 3

[0093] Implementation case 3: color pattern, the inner surface of the plate is surrounded by a camouflage pattern, and the center is a heart-shaped pattern.

[0094] like figure 1As shown, first, make the sponge pattern

[0095] Make a camouflage sponge pattern: use a wooden board about 3cm thick to process it into a circle with the same diameter as the plate, put a handle on one side of the wooden board, and glue a piece of thick sponge about 7cm thick and larger in area than the wooden board with glue on the other side, and then Cut off the excess sponge according to the outline of the board, process the outline of the sponge on the grinding wheel into a radian close to the inner outline of the plate, cut off the sponge in the center, make the sponge into a ring, and then smooth the outline around it. Grab the surface of the processed sponge piece by piece by hand to form a relatively uniform honeycomb shape;

[0096] Make a red heart sponge pattern: use a 3cm thick wooden...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com