Electrostatic suppressing element and production method thereof

A technology of electrostatic suppression and manufacturing method, applied in electrical components, resistor manufacturing, resistor components and other directions, can solve the problems of high product trigger voltage, electrode end face ablation, high production cost, low product cost and short response time , the effect of low leakage current

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

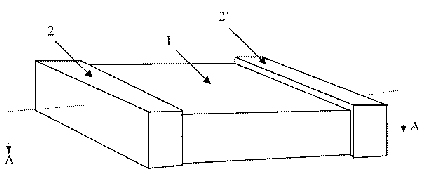

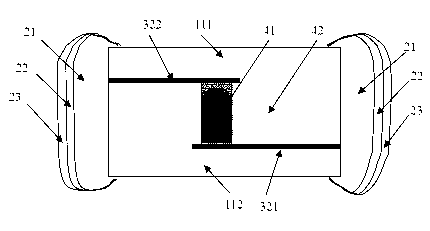

[0031] Such as figure 2 As shown, an electrostatic suppression component includes a ceramic substrate 1, a left external electrode 2 and a right external electrode 2', the left external electrode 2 and the right external electrode 2' are respectively located at both ends of the ceramic substrate 1, and the ceramic substrate 1 is protected by the upper layer 112, the second electrode layer 321, the via layer 42, the first electrode layer 322 and the lower protective layer 111, the via layer 42 is provided with an opening, and is filled with the pressure-sensitive ceramic functional phase 41, the via hole The upper and lower surfaces of the openings in the layer 42 are covered by printed electrode layers (322, 321). The printed electrode layers are alternately led out from both ends of the product, and each printed electrode layer is only connected to one external electrode. The thickness and shape of the printed electrode layer have no significant impact on product performance...

Embodiment 2

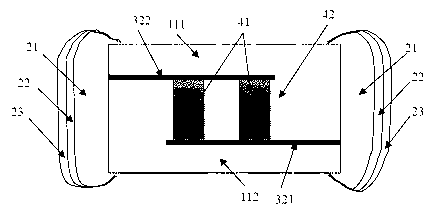

[0034] Such as image 3 As shown, an electrostatic suppression component includes a ceramic substrate 1, a left external electrode 2 and a right external electrode 2', the left external electrode 2 and the right external electrode 2' are respectively located at both ends of the ceramic substrate 1, and the ceramic substrate 1 is protected by the upper layer 112, the second electrode layer 321, the via layer 42, the first electrode layer 322 and the lower protective layer 111, the via layer 42 is provided with two openings, and both are filled with the pressure-sensitive ceramic functional phase 41, The upper and lower surfaces of the openings in the through-hole layer 42 are covered by printed electrode layers (322, 321), and the printed electrode layers are alternately drawn from both ends of the product, and each printed electrode layer is only connected to one external electrode .

[0035] Others are similar to Example 1.

Embodiment 3

[0037] Such as Figure 4 As shown, an electrostatic suppression component includes a ceramic substrate 1, a left external electrode 2 and a right external electrode 2', the left external electrode 2 and the right external electrode 2' are respectively located at both ends of the ceramic substrate 1, and the ceramic substrate 1 contains three layers The via layer 42 is composed of an upper protective layer 112 and a lower protective layer 111 located in the outermost layer. Each via layer 42 is provided with an opening and is filled with a pressure-sensitive ceramic functional phase 41. The via layer The upper and lower surfaces of the openings in 42 are covered by printed electrode layers, and the printed electrode layers on the upper and lower surfaces of the through-hole layer 42 are alternately arranged. The printed electrode layers are respectively drawn out from both ends of the product alternately. The side external electrodes are connected.

[0038] Others are similar ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com