Carbon nanometer tube negative electrode and method for preparing carbon nanometer tube negative electrode

A carbon nanotube cathode and carbon nanotube technology, which is applied in the field of field emission, can solve problems such as unsatisfactory adhesion improvement, reduced emission current density, and poor wettability of carbon nanotubes, achieving high emission current density and good stability , good effect on surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

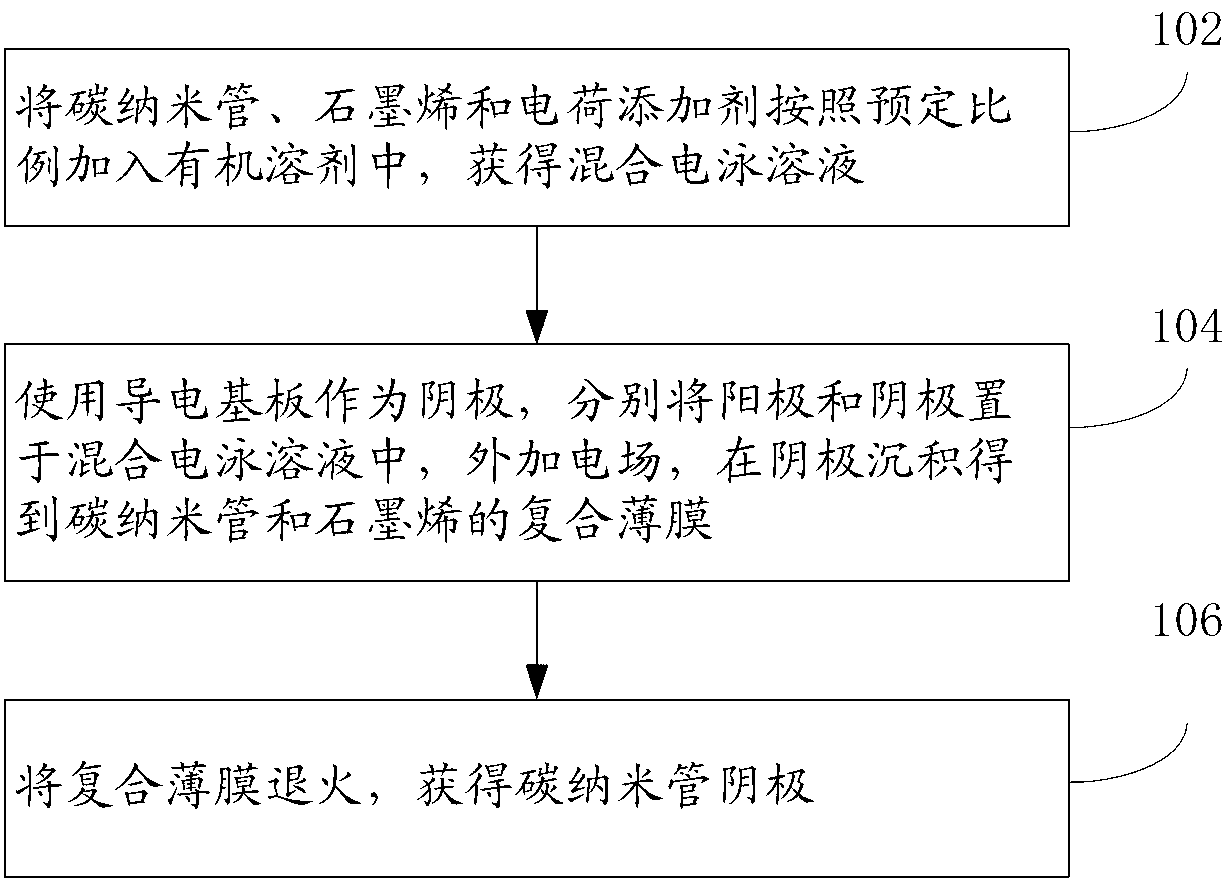

[0026] Such as figure 1 As shown, the carbon nanotube cathode preparation method of the present application, an embodiment thereof, comprises the following steps:

[0027] Step 102: adding carbon nanotubes, graphene and charge additives into an organic solvent according to a predetermined ratio to obtain a mixed electrophoresis solution.

[0028] Wherein, the weight ratio of carbon nanotubes and graphene is 2-10, and in one embodiment, the weight ratio of carbon nanotubes and graphene is 3-6. The carbon nanotubes include at least one of single-wall carbon nanotubes, multi-wall carbon nanotubes, modified single-wall carbon nanotubes, and modified multi-wall carbon nanotubes. The carbon nanotubes have a length of 10 to 100 μm. In one embodiment, the carbon nanotubes preferably have a length of 10-20 μm. Graphene includes single-layer graphene and / or multi-layer graphene, that is, graphene may be single-layer graphene, multi-layer graphene or a mixture of single-layer graphene...

Embodiment 1

[0045] Add carbon nanotubes and graphene to absolute ethanol at a weight ratio of 2:1, and add 1% MgCl 2 (Based on the total weight of carbon nanotubes and graphene) as a charge additive, the concentration of carbon nanotubes and graphene is 1mg / ml, and ultrasonically dispersed for 12h to obtain a uniform mixed solution of carbon nanotubes and graphene; The silicon chip is used as the cathode, and the oxygen-free copper sheet is used as the anode, inserted into the electrophoresis solution, the distance between the cathode and the anode is 5cm, the DC electrophoresis voltage is 200V, and the electrophoresis time is 10s to obtain a composite film of carbon nanotubes and graphene; will be attached to the conductive substrate The composite film of carbon nanotubes and graphene was dried at 90 °C for 10 min, and then in N 2 Annealing at 800° C. for 1 h under a protective atmosphere to prepare a carbon nanotube / graphene composite film cathode.

Embodiment 2

[0047] Add carbon nanotubes and graphene to absolute ethanol at a weight ratio of 10:1, and add 50% MgSO 4 (Based on the total weight of carbon nanotubes and graphene) as charge additives, the concentration of carbon nanotubes and graphene is 0.01mg / ml, ultrasonically dispersed for 1h, to obtain a uniform mixed solution of carbon nanotubes and graphene; to print Ag The glass sheet of the electrode is used as the cathode, and the oxygen-free copper sheet is used as the anode, which is inserted into the electrophoresis solution. The carbon nanotube and graphene composite film on the conductive substrate was dried at 90° C. for 10 min, and then annealed at 600° C. for 1 h under an Ar protective atmosphere to prepare a carbon nanotube and graphene composite film cathode.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com