Thermophoretic air purifying device and method

An air purification device and thermophoresis technology, which is applied in the field of air cleaning methods and devices based on the principle of thermophoresis, can solve the problems of high filter screen price, high cost of fiber filtration, secondary pollution, etc., and achieve good filtering effect and air filtration High efficiency and remarkable filtering effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

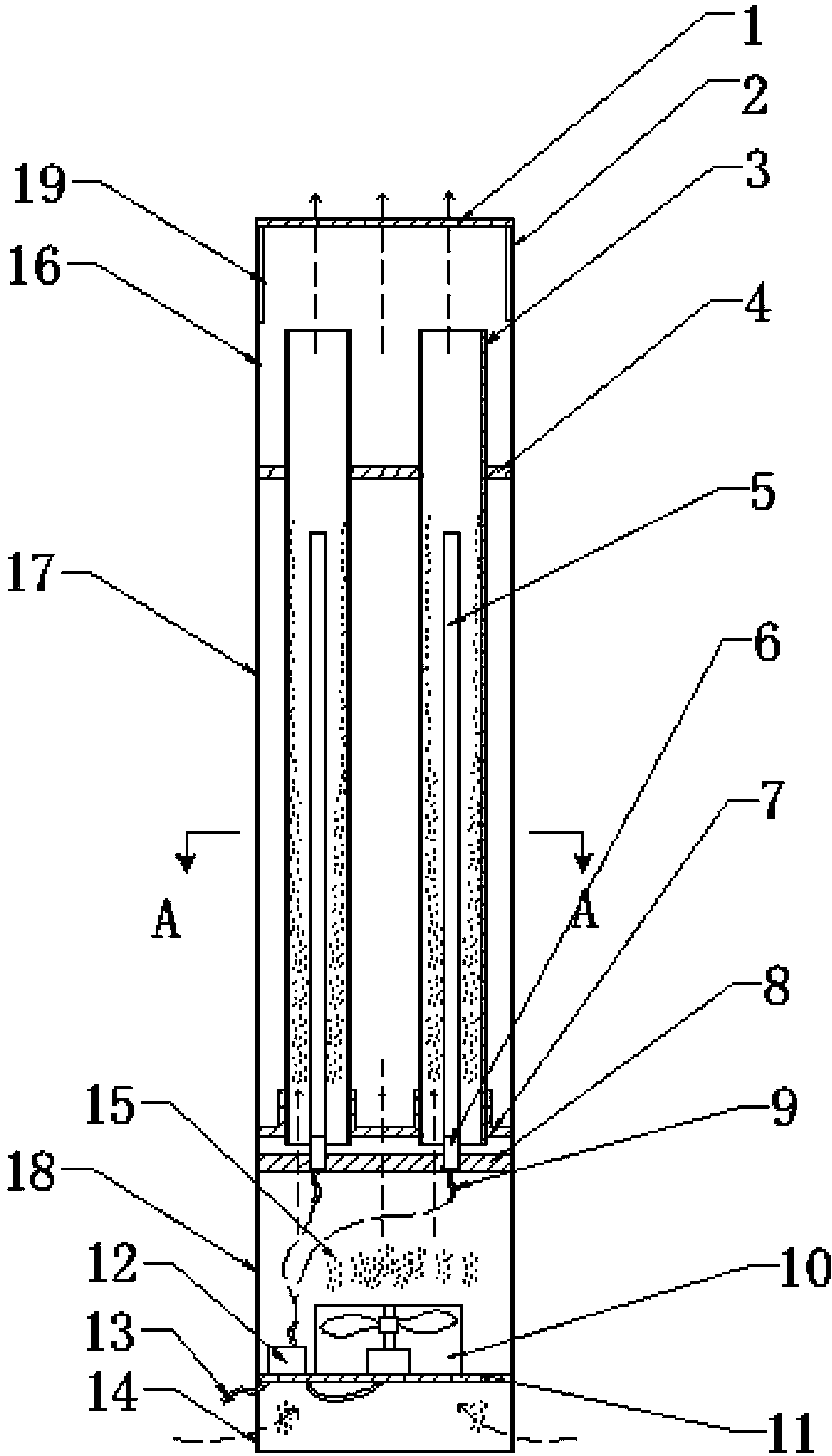

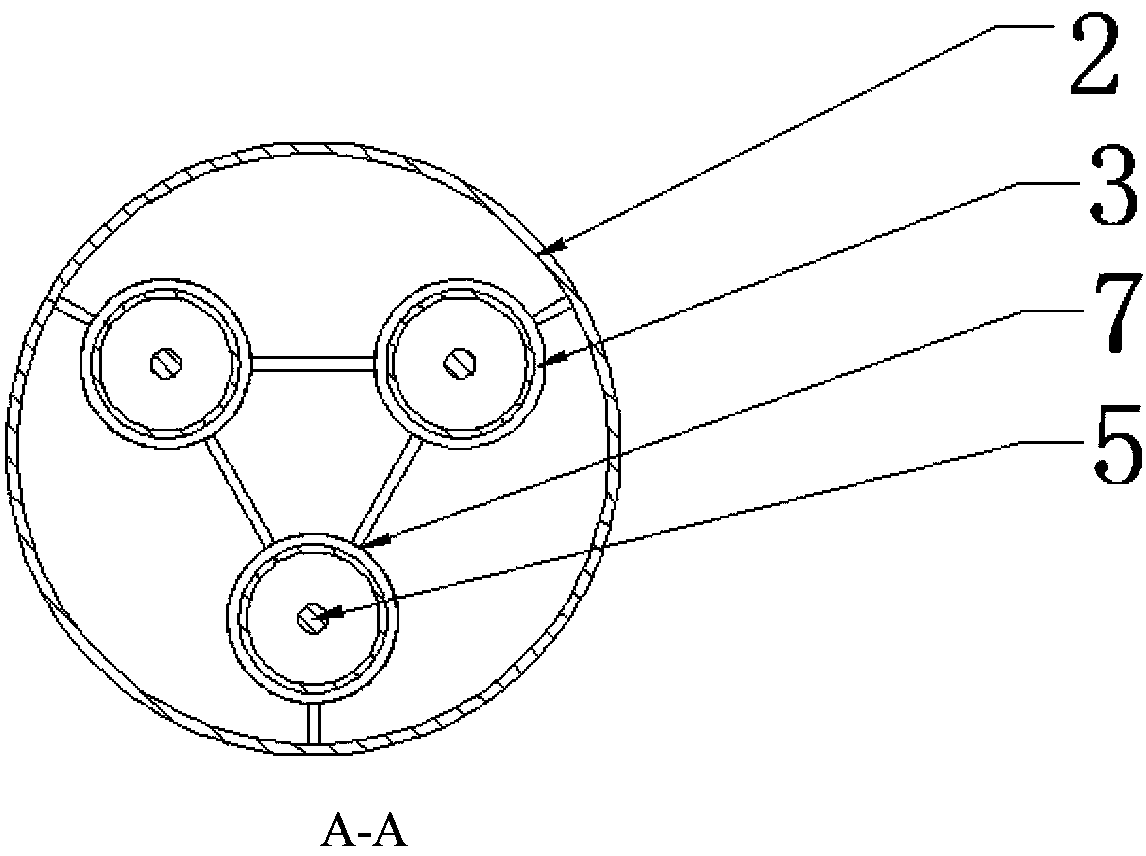

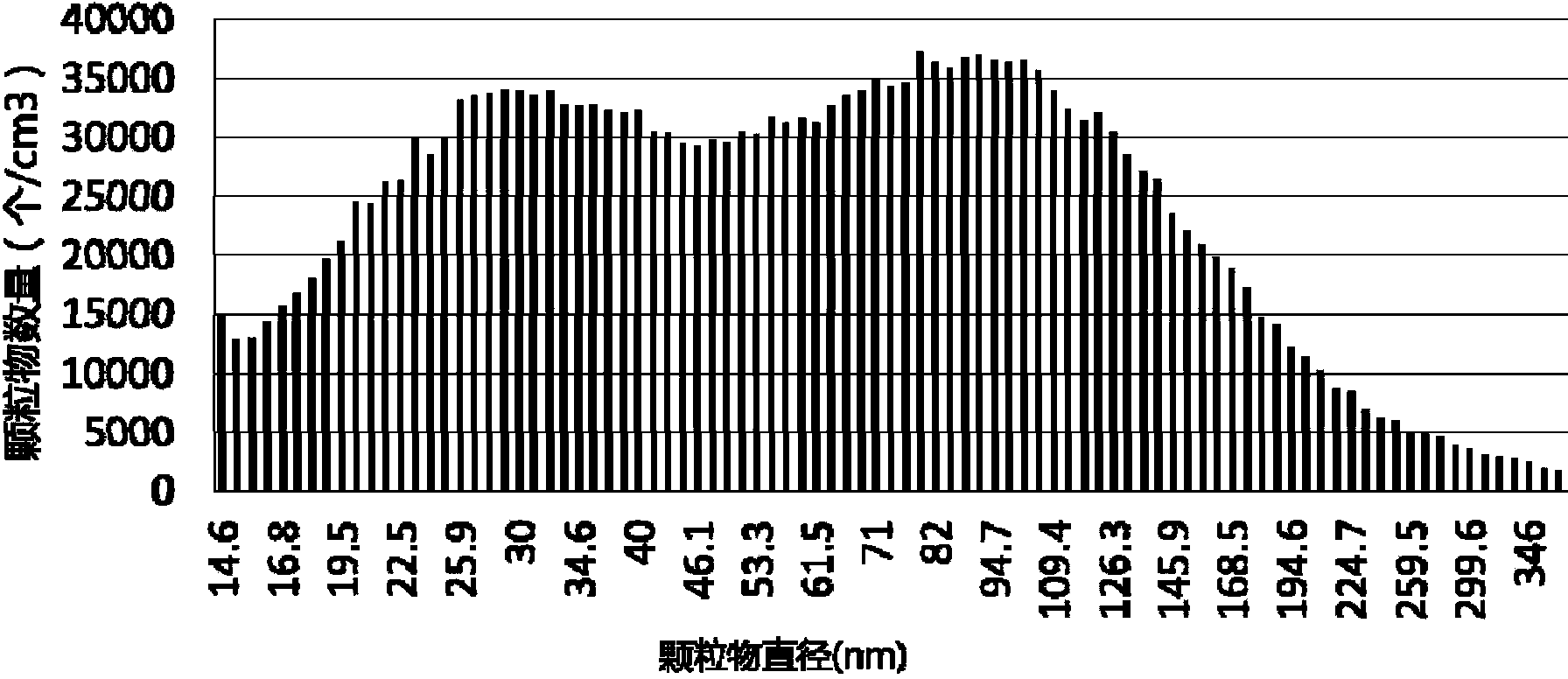

[0027] Take three thermophoresis dust accumulation pipes, the diameter of the thermophoresis dust accumulation pipe is 2.5cm, the length is 25cm, the material is aluminum; the air volume of the blower is 60m 3 / h; 35W heating rod is selected as the heating element. The air near the heating rod in the thermophoresis dust accumulation pipe is 400°C when it is working stably, the temperature of the outer wall of the thermophoresis dust accumulation pipe is 50°C, and the temperature gradient reaches 280°C / cm. The mixed air temperature is about 60°C. The distance between the two thermophoresis dust collection pipes is 2cm, and the average distance between the thermophoresis dust collection pipe and the inner wall of the device shell is 1.5cm.

[0028] Filter sample performance was tested through three experiments:

[0029] 1) Pass the efficiency test once

[0030] Instruments used: TSI3080 (detection range 14nm ~ 620nm), LPC laser dust particle counter (detection range > 300nm), ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com