Preparation method for two-dimensional ultrathin mesh-shaped ZnO nano photocatalyst

A nano-photocatalyst and ultra-thin technology, applied in chemical instruments and methods, physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, etc., can solve the problem of small increase in photocatalytic activity and reduction The area of the photocatalyst absorbing light, weakening the ability of the semiconductor to absorb light, etc., to achieve the effect of improving quantum conversion efficiency, simple production process, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

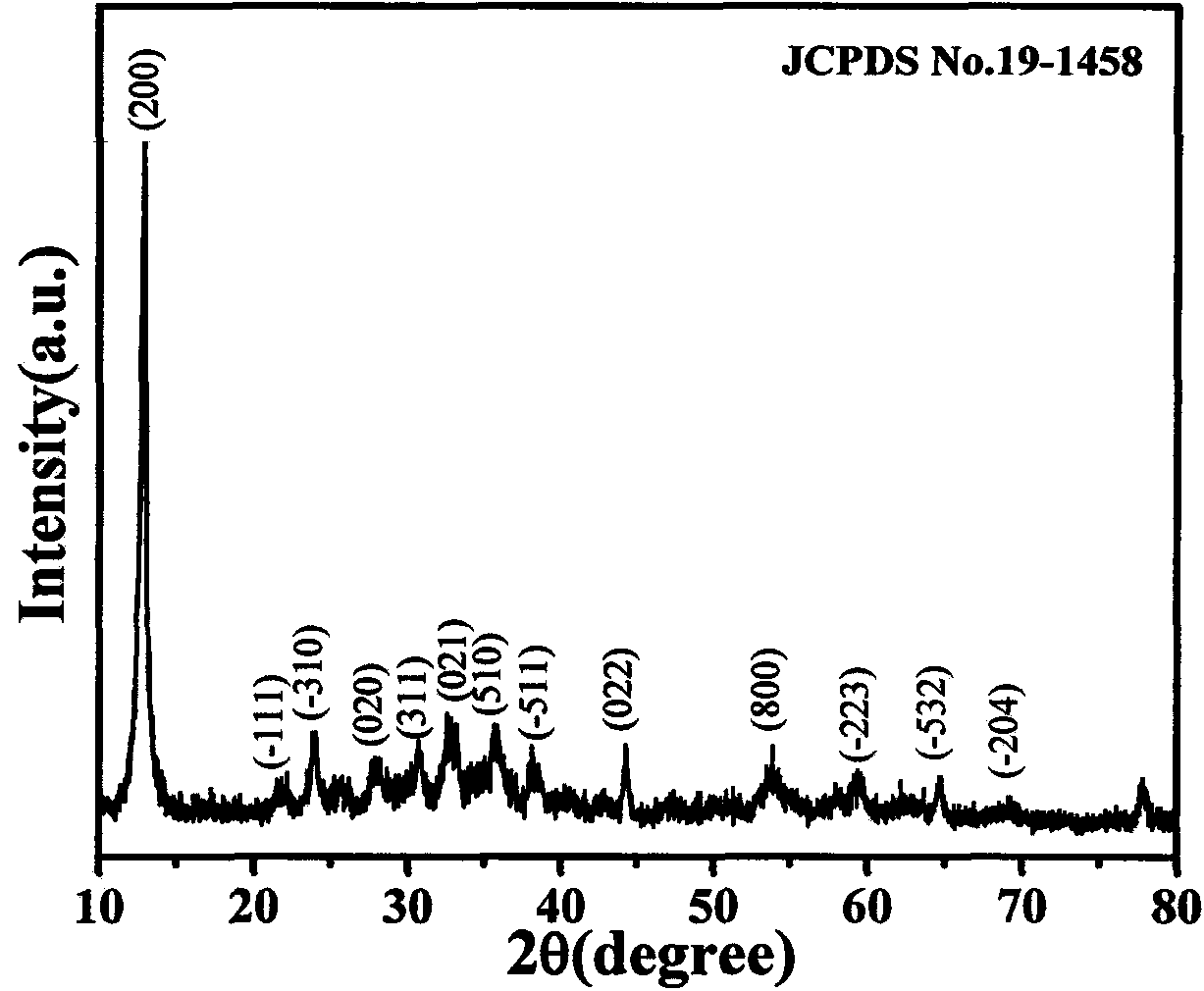

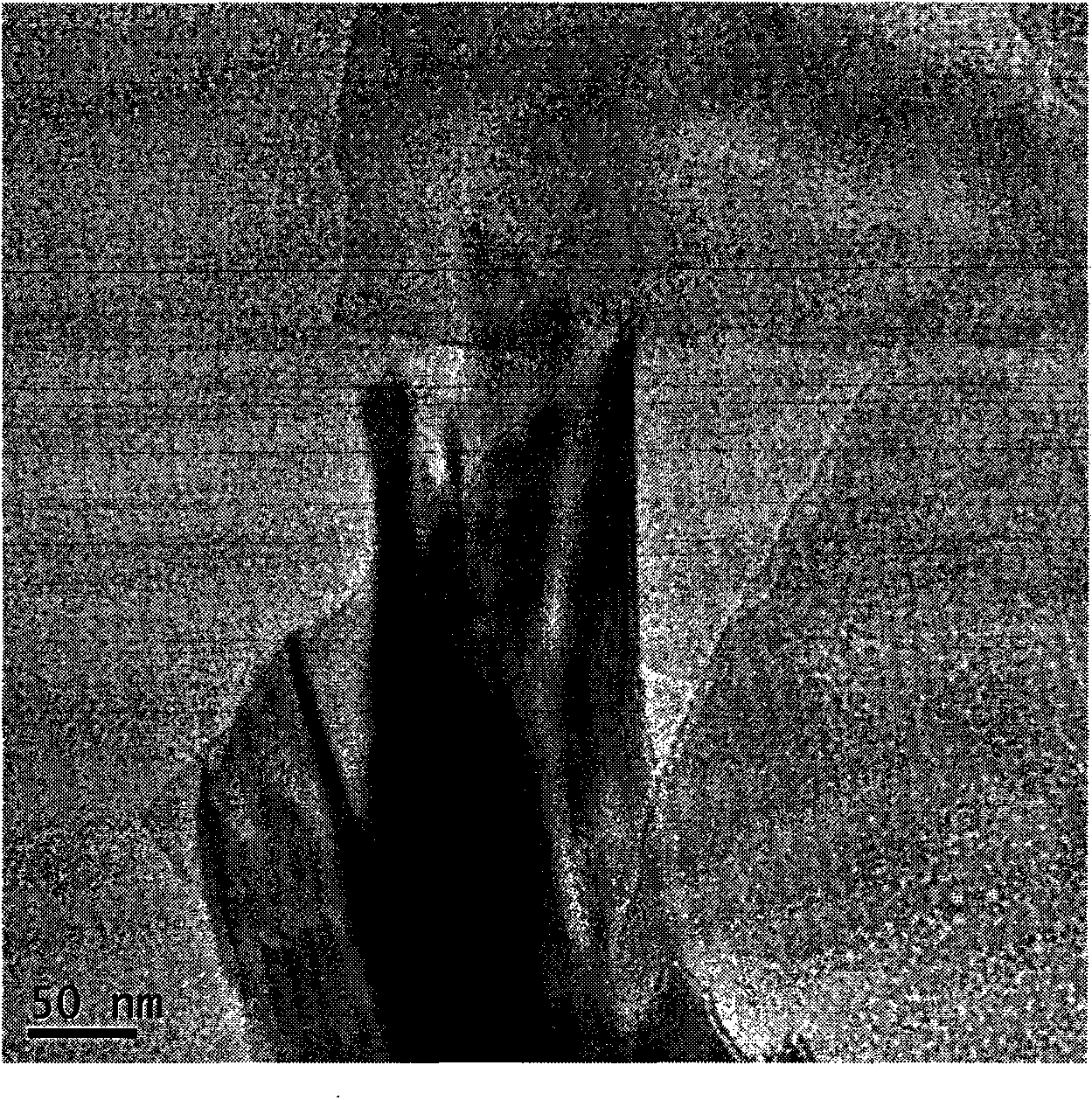

[0026] A preparation method of a two-dimensional ultrathin mesh ZnO nano photocatalyst, comprising the steps of:

[0027] (1) At room temperature, add zinc acetate dihydrate, 2-2'-bipyridyl, and urea with a molar ratio of 1:1:5 to a mixed solution of ethanol and distilled water at a volume ratio of 1:1, and stir magnetically to make it Fully dissolve, then continue stirring for 1 hour to obtain a uniform mixed solution; the concentration of zinc acetate in the mixed solution is 1.0×10 -2 M, the concentration of 2-2'-bipyridine is 1.0×10 -2 M, the concentration of urea is 5.0×10 -2 M;

[0028] (2) transfer the obtained mixed solution into the inner lining of the autoclave, and place the autoclave at a temperature of 120° C. for heating for 12 hours to obtain a white flocculent precipitate, and the heating equipment is a blast drying oven;

[0029] (3) The white flocculent precipitate was washed several times with ethanol and distilled water respectively, and then centrifuged...

Embodiment 2

[0033] A preparation method of a two-dimensional ultrathin mesh ZnO nano photocatalyst, comprising the steps of:

[0034] (1) At room temperature, add zinc acetate dihydrate, 2-2'-bipyridyl, and urea with a molar ratio of 1:1:5 to a mixed solution of ethanol and distilled water at a volume ratio of 1:1, and stir magnetically to make it Fully dissolve, then continue stirring for 1 hour to obtain a uniform mixed solution; the concentration of zinc acetate in the mixed solution is 5.0×10 -3 M, the concentration of 2-2'-bipyridine is 5.0×10 -3 M, the concentration of urea is 2.5×10 -2 M;

[0035] (2) transfer the obtained mixed solution into the inner lining of the autoclave, and place the autoclave at a temperature of 150° C. for heating for 12 hours to obtain a white flocculent precipitate, and the heating equipment is a blast drying oven;

[0036] (3) The white flocculent precipitate was washed several times with ethanol and distilled water, and then centrifuged, and then dr...

Embodiment 3

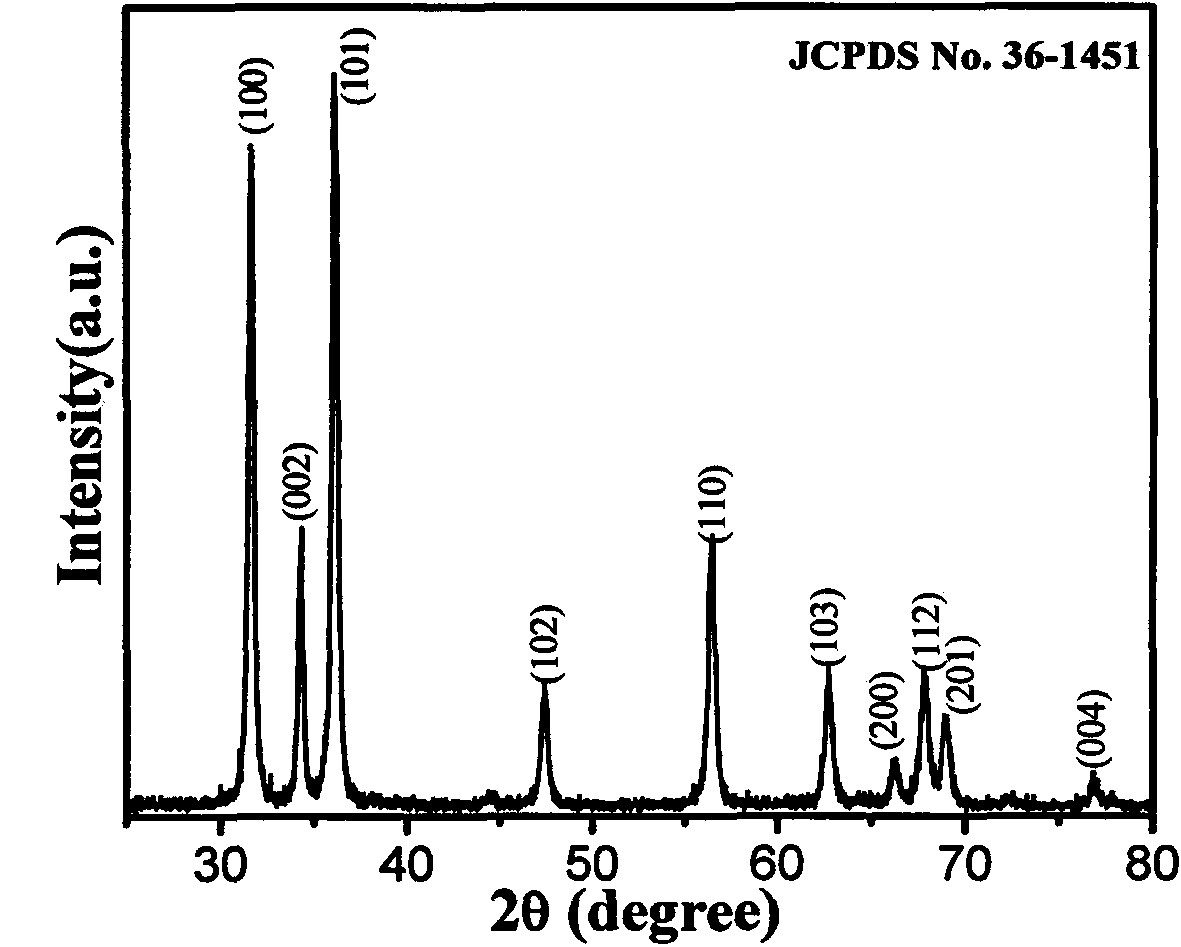

[0040] A preparation method of a two-dimensional ultrathin mesh ZnO nano photocatalyst, comprising the steps of:

[0041] (1) At room temperature, add zinc acetate dihydrate, 2-2'-bipyridyl, and urea with a molar ratio of 1:1:5 to a mixed solution of ethanol and distilled water at a volume ratio of 1:1, and stir magnetically to make it Fully dissolve, then continue stirring for 1 hour to obtain a uniform mixed solution; the concentration of zinc acetate in the mixed solution is 1.0×10 -2 M, the concentration of 2-2'-bipyridine is 1.0×10 -2 M, the concentration of urea is 5.0×10 -2 M;

[0042] (2) Transfer the obtained mixed solution into the inner lining of the autoclave, place the autoclave at a temperature of 180° C. and heat for 12 hours to obtain a white flocculent precipitate, and the heating equipment is a blast drying oven;

[0043] (3) The white flocculent precipitate was washed several times with ethanol and distilled water, and then centrifuged, and then dried in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com