Short-cut denitrification system and method combining coal chemical industry wastewater outside loop moving bed reactor and biological aerated filter

A technology of moving bed biofilm and aerated biological filter is applied in chemical instruments and methods, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., and can solve the problems of poor removal of total nitrogen in water, etc. Achieve the effect of excellent removal effect and excellent total nitrogen removal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

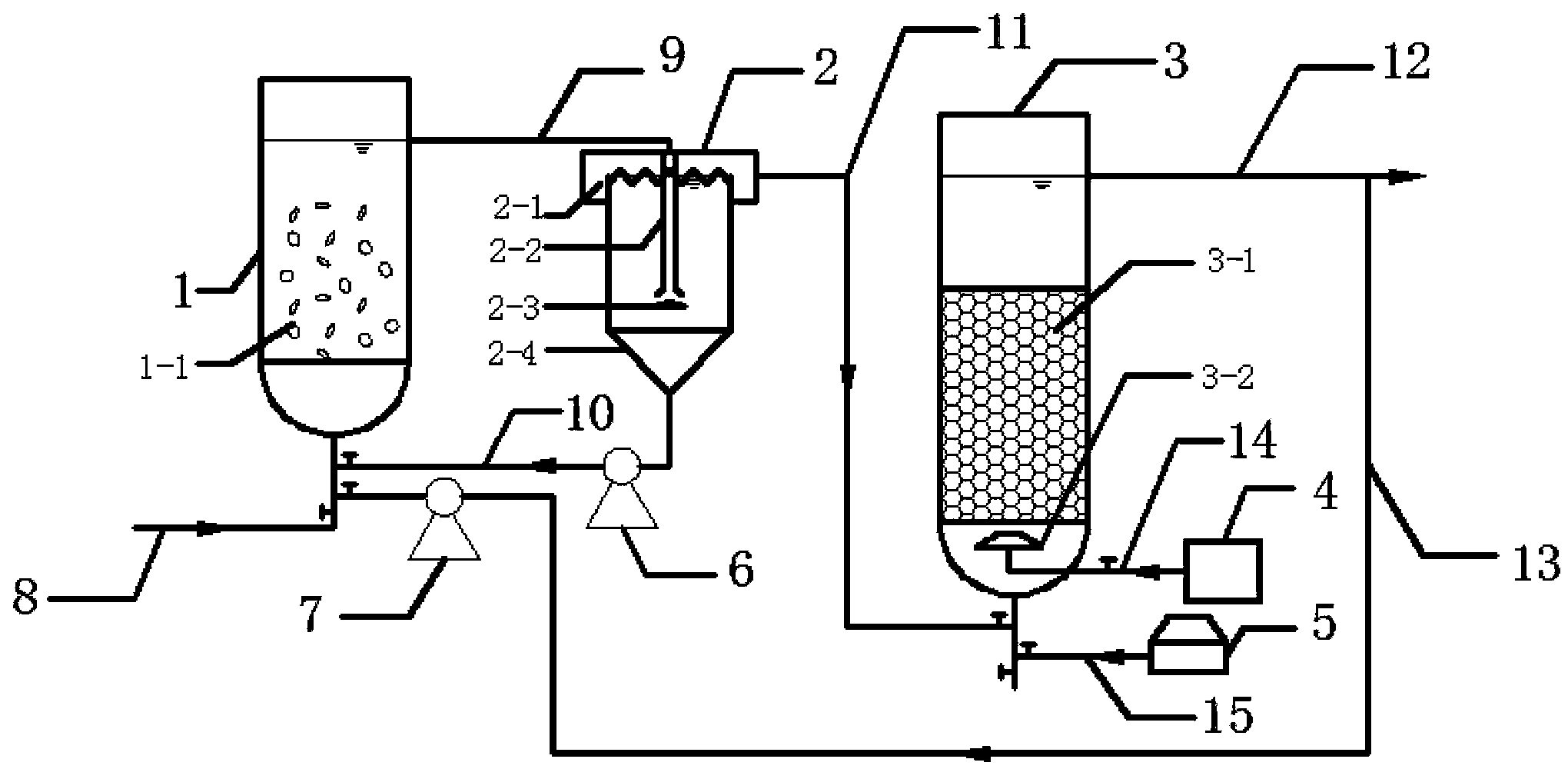

[0019] Specific implementation mode 1: In this embodiment, the combined short-range denitrification system of coal chemical wastewater external circulation moving bed reactor and biological aerated filter consists of moving bed biofilm reactor 1, sedimentation tank 2, biological aerated filter 3, air Compressor 4, clear water tank 5, sludge return pump 6, nitrifying liquid return pump 7, water inlet pipe 8, moving bed biofilm reactor outlet pipe 9, sludge return pipe 10, sedimentation tank outlet pipe 11, outlet pipe 12, The nitrifying liquid return pipe 13, the compressed air pipe 14 and the clean water pipe 15 are composed;

[0020]The carrier 1-1 is filled in the moving bed biofilm reactor 1, the water inlet pipe 8 communicates with the water inlet at the bottom of the moving bed biofilm reactor 1, and the moving bed biofilm reactor 1 passes through the moving bed biofilm reactor outlet pipe 9 and The central pipe 2-2 in the sedimentation tank 2 is connected to each other, ...

specific Embodiment approach 2

[0022] Specific embodiment two: the difference between this embodiment and specific embodiment one is that the carrier 1-1 is a polyethylene disc in the moving bed biofilm reactor 1, the diameter of the disc is 22mm, the thickness is 1mm, and the density is 0.8g / cm 3 , The carrier filling rate is 35%. Other devices are the same as in the first embodiment.

[0023] In this embodiment, before the operation of the moving bed biofilm reactor, the carrier needs to undergo 30 days of film-hanging acclimation. The process of film-hanging domestication is to put the disc-shaped carrier into the anoxic sludge for intermittent cultivation. The initial concentration of the inoculated sludge is 3000mgVSS / L, after 30 days of film-hanging, a uniform and stable biofilm is formed on the surface of the carrier, and the biomass on the carrier is 0.28g / g.

specific Embodiment approach 3

[0024] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is that the filter material 3-1 in the biological aerated filter 3 is a ceramsite homogeneous filter material, with an average diameter of 2 mm, a shape factor of 0.63, and a true density 1.5g / cm 3 , bulk density 0.86g / cm 3 , porosity 42.5%. Other devices are the same as those in Embodiment 1 or 2.

[0025] The filter materials in this embodiment are arranged in layers, and the height between filter layers is 1.2m. Before the operation of the biological aerated filter, the filter material needs to be acclimatized by hanging film for 30 days. The initial concentration of inoculated sludge on the filter material is 2500mgVSS / L, the dissolved oxygen is controlled at 2mg / L, and the acclimatization temperature is 30°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com