Anaerobic ammonia oxidation denitrification and phosphorus removal system and method

An anaerobic ammonia oxidation, nitrogen and phosphorus removal technology, applied in chemical instruments and methods, aerobic and anaerobic process treatment, water treatment parameter control, etc., can solve the general nitrogen removal effect, poor water quality stability, electronic It is difficult to control the stability of acceptor nitrite nitrogen, so as to solve the effect of enrichment and separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

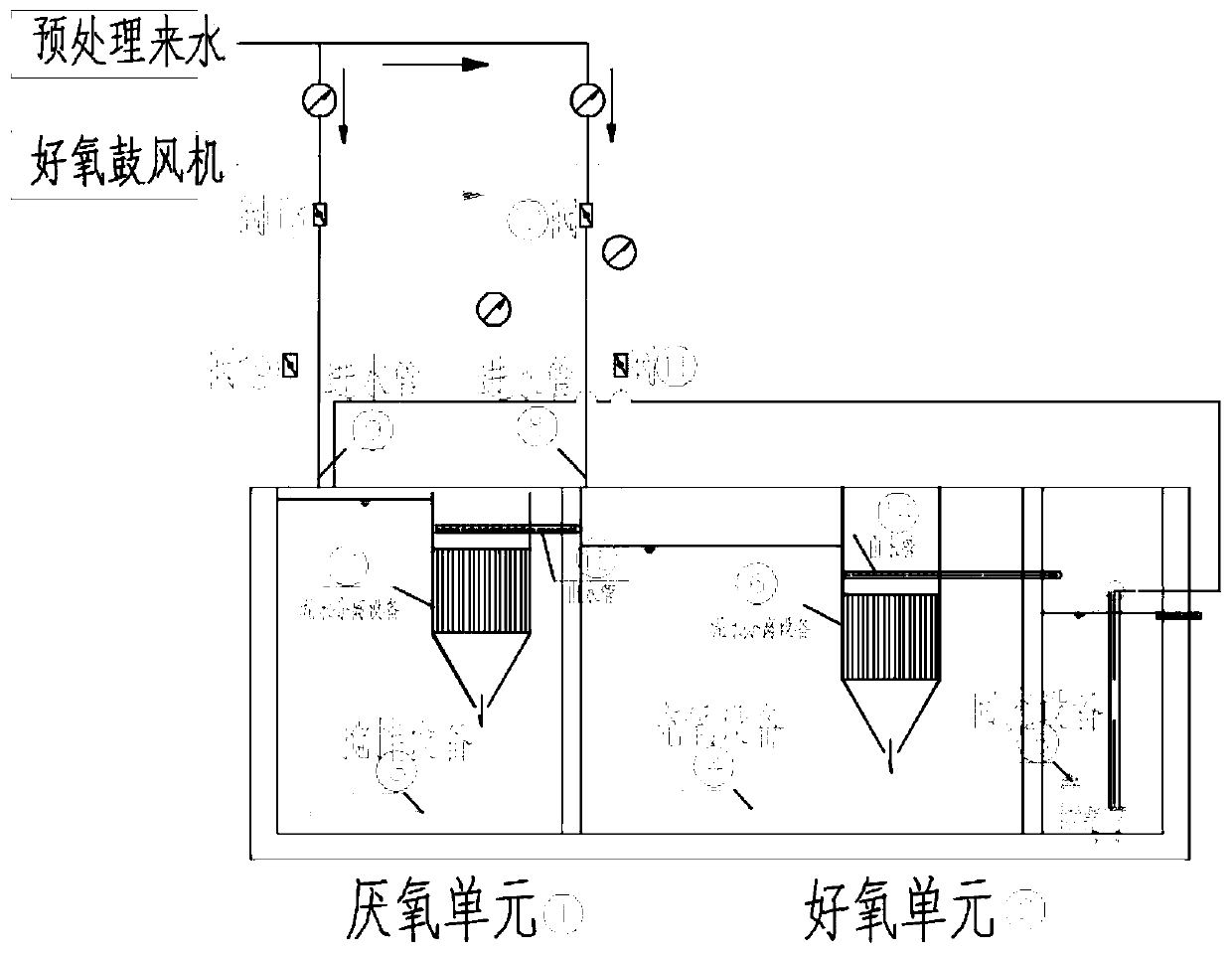

[0071] The schematic structural diagram of the anaerobic ammonium oxidation denitrification and phosphorus removal system provided in Example 1 of the present invention can be found in figure 1 Shown; Wherein, 1 is the anaerobic unit (its early inoculation anammox bacteria), 2 is the aerobic unit, 3 is the mixing equipment, 4 is the oxygenation equipment, 5 is the reflux equipment, 6 is the mud-water separation equipment (good oxygen unit), 7 is the mud-water separation equipment (anaerobic unit), 8 is the water inlet pipe (aerobic unit), 9 is the water inlet pipe (anaerobic unit), 10 is the mixing equipment control valve, 11 is the oxygenation equipment control valve, 12 is the water inlet control valve (aerobic unit), 13 is the water inlet control valve (anaerobic unit), 14 is the water outlet pipe (aerobic unit), and 15 is the water outlet pipe (anaerobic unit).

[0072] The working process of the anammox denitrification and phosphorus removal system provided in Example 1 o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com