Tobacco humectant 1-O-hydroxyethyl-D-mannopyranose and preparation method thereof

A technology of mannose and humectant for tobacco, which is applied in the preparation of sugar derivatives, chemical instruments and methods, tobacco, etc., and can solve the problems of no moisture-proof effect, precipitation, low temperature and easy solidification, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

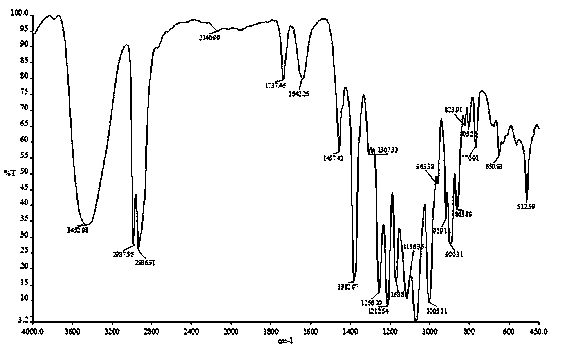

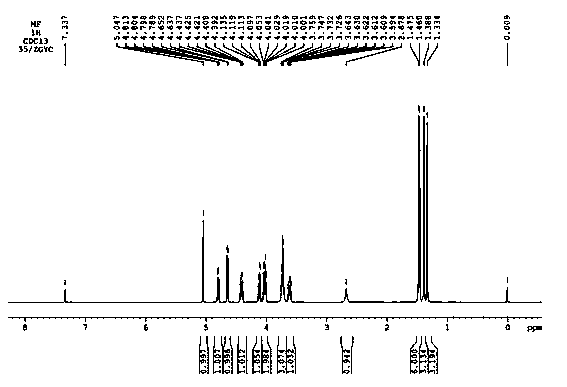

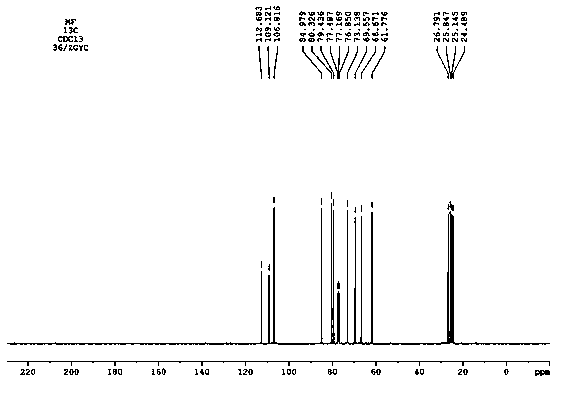

Image

Examples

Embodiment 1

[0030] The preparation method of 1-O-hydroxyethyl-D-mannopyranose, it comprises the steps:

[0031] (1) Preparation of 1-O-hydroxyethyl-2,3:5,6-di-O-isopropylidene-α-D-mannofuranose (Ⅱ)

[0032] Weigh 6.0 g of 1-O-carboxymethyl-2,3:5,6-di-O-isopropylidene-α-D-mannofuranosyl tert-butyl ester (Ⅰ) into a 250 mL three-necked flask, add 51 mL THF, stirred by magnetic force to dissolve, then protected by nitrogen, cooled in ice-water bath to below 10°C (preferably between 0-10°C), then slowly added LiAlH40.027mol, raised the temperature and reacted at 10°C 3h, TLC monitored the entire reaction process (V petroleum ether: V ethyl acetate = 3: 2), then slowly dropwise added 18mL ethyl acetate aqueous solution (V ethyl acetate: V water = 1:1) to end the reaction, filtered the precipitate, Concentration under reduced pressure gave 3.469 g of a colorless transparent viscous liquid (II), with a yield of 71.13%.

[0033] (2) Preparation of 1-O-hydroxyethyl-D-mannopyranose (Ⅲ)

[0034] A...

Embodiment 2

[0036] The preparation method of 1-O-hydroxyethyl-D-mannopyranose, it comprises the steps:

[0037] (1) Preparation of 1-O-hydroxyethyl-2,3:5,6-di-O-isopropylidene-α-D-mannofuranose (Ⅱ)

[0038] Weigh 6.0 g of 1-O-carboxymethyl-2,3:5,6-di-O-isopropylidene-α-D-mannose furanose tert-butyl ester (Ⅰ) into a 250 mL three-necked flask, add 60 mL THF, stirred by magnetic force to dissolve, then protected by nitrogen, cooled in an ice-water bath to below 10°C (preferably between 0-10°C), then slowly added LiAlH40.03mol, raised the temperature and reacted at 15°C 4h, TLC monitored the entire reaction process (V petroleum ether: V ethyl acetate = 3: 2), and then slowly dropwise added 30mL ethyl acetate aqueous solution (V ethyl acetate: V water = 1:1) to end the reaction, filtered the precipitate, Concentration under reduced pressure gave 4.338 g of a colorless transparent viscous liquid (II), with a yield of 88.95%.

[0039] (2) Preparation of 1-O-hydroxyethyl-D-mannopyranose (Ⅲ)

...

Embodiment 3

[0042] The preparation method of 1-O-hydroxyethyl-D-mannopyranose, it comprises the steps:

[0043] (1) Preparation of 1-O-hydroxyethyl-2,3:5,6-di-O-isopropylidene-α-D-mannofuranose (Ⅱ)

[0044] Weigh 6.0 g of 1-O-carboxymethyl-2,3:5,6-di-O-isopropylidene-α-D-mannofuranosyl tert-butyl ester (I) into a 250 mL three-necked flask, add 96 mL THF, stirred by magnetic force to dissolve, then protected by nitrogen, cooled in an ice-water bath to below 10°C (preferably between 0-10°C), then slowly added LiAlH40.033mol, raised the temperature and reacted at 25°C 5h, TLC monitored the entire reaction process (V petroleum ether: V ethyl acetate = 3: 2), and then slowly dropwise added 40mL ethyl acetate aqueous solution (V ethyl acetate: V water = 1:1) to end the reaction, filtered the precipitate, Concentration under reduced pressure gave 4.2 g of a colorless transparent viscous liquid (II), with a yield of 86.12%.

[0045] (2) Preparation of 1-O-hydroxyethyl-D-mannopyranose (Ⅲ)

[0046...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com