Supercharging device of formation pressure measurement-while-drilling instrument

A technology for formation pressure and measuring instruments, which is applied to fluid pressure actuating devices, fluid pressure converters, and earth-moving drilling and mining, etc., can solve the problems that cannot be directly used as a hydraulic power source, the formation pressure error is large, and the tool is difficult to run. Achieve the effect of widening the scope of use, prolonging the service life and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

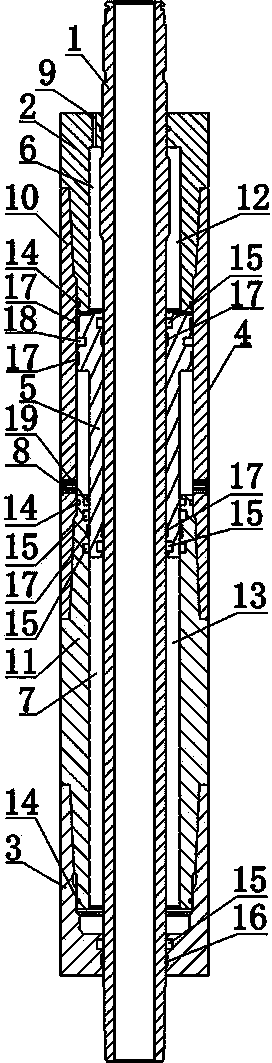

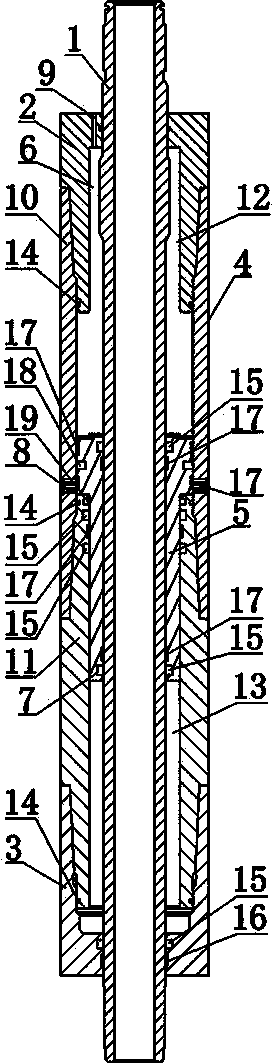

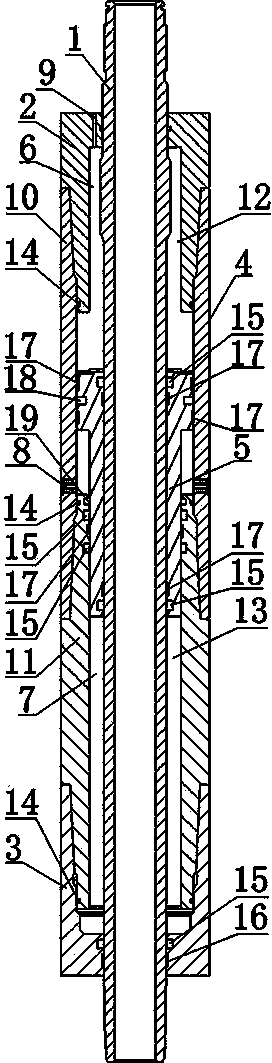

[0019] Such as figure 1As shown, a pressurization device for a formation pressure measurement instrument while drilling, which includes a hollow cylindrical central shaft 1, a test joint I2, a pressurization structure and a test joint II3 that are sequentially sleeved outside the central shaft 1, and the upper and lower ends of the central shaft 1 It is threaded and connected to the main body of the formation pressure measurement instrument while drilling to achieve fixation. The booster structure includes a housing 4 and at least one booster piston 5 arranged in the housing 4 and sleeved on the outside of the central shaft 1. The piston 5 can slide axially on the central shaft 1, one end of the test joint I2 is tightly fitted outside the central shaft 1, the other end of the test joint I2 is tightly connected to one end of the housing 4, and the other end of the housing 4 is tightly connected to the test joint One end of II3 and the other end of test joint II3 are tightly fit...

Embodiment 2

[0027] As mentioned above, in the low-pressure mud cylinder 12 at the large end of the upper end of the booster piston 5, the pressure difference between the inside and outside of the drill string is applied, and the high-pressure hydraulic cylinder at the small end of the lower end of the booster piston 5 is filled with hydraulic oil. The volume of hydraulic oil action space, according to the principle of mechanical balance, the ratio of the pressure in the high-pressure hydraulic cylinder at the lower end of the booster piston 5 to the pressure in the low-pressure mud cylinder 12 at the upper end is the area ratio of the upper and lower ends of the booster piston 5, and the actual use A reasonable size of boost piston 5 can be determined according to the required boost pressure. In actual use, a higher boost pressure is often required. Simply increasing the boost pressure by adjusting the size of the boost will weaken the strength of the boost device, making it impossible to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com