Apparatus and method for detecting multiple optical axis consistency of platform photoelectric instrument

A technology for optoelectronic instruments and detection devices, which is used in optical instrument testing, measuring devices, and optical devices, etc., can solve the problems of heavy weight, large volume, and high environmental requirements, and achieve the effects of small weight, small volume, and high degree of automation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0066] Embodiment 1: Multi-optical axis consistency detection device for a platform photoelectric instrument.

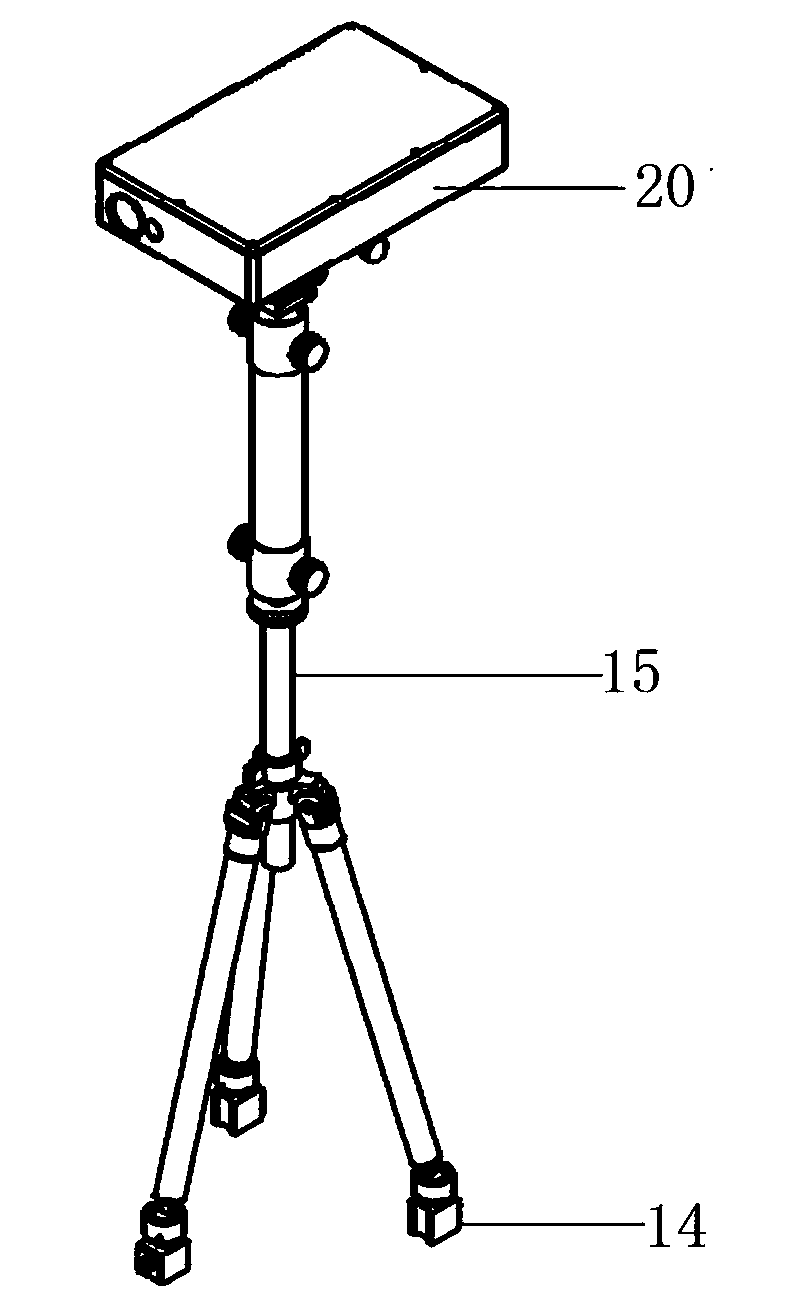

[0067] The multi-optical axis consistency detection device of the platform photoelectric instrument provided by the present invention includes a detection host, a support mechanism and a data control and processing system.

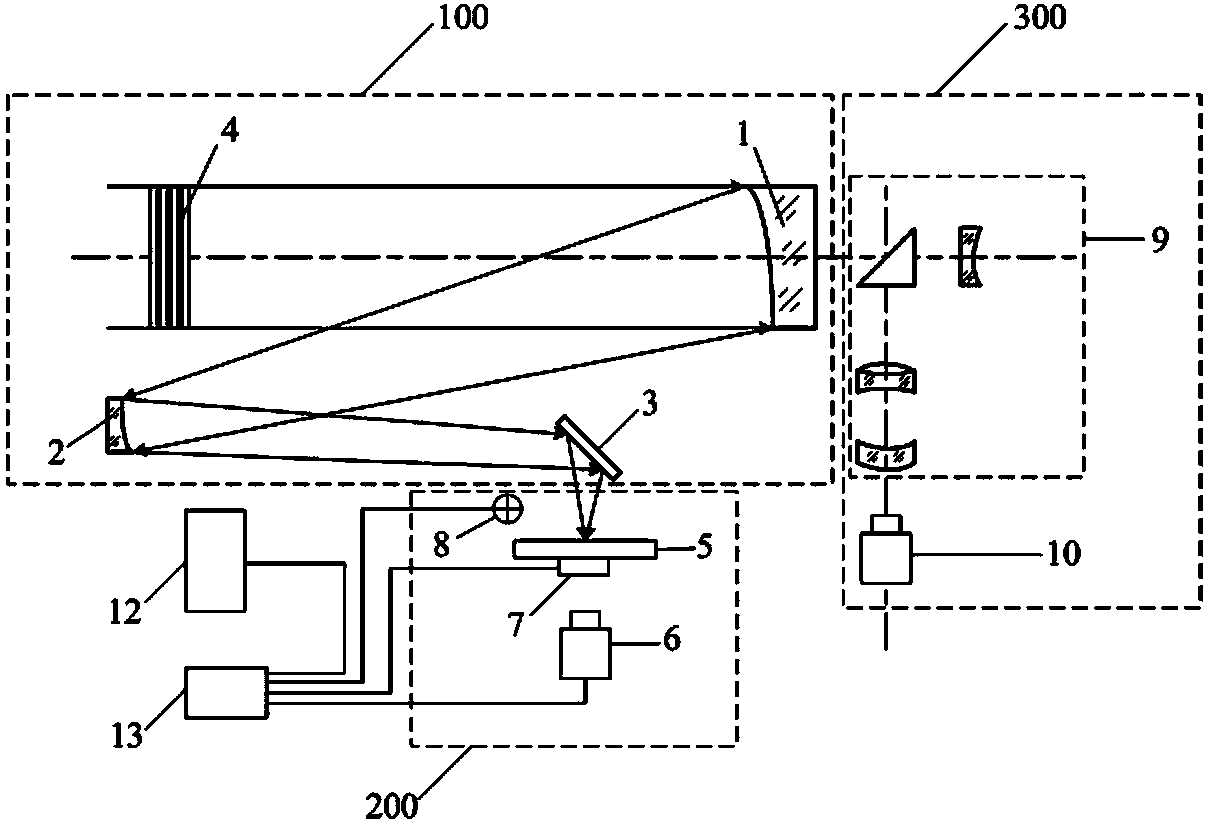

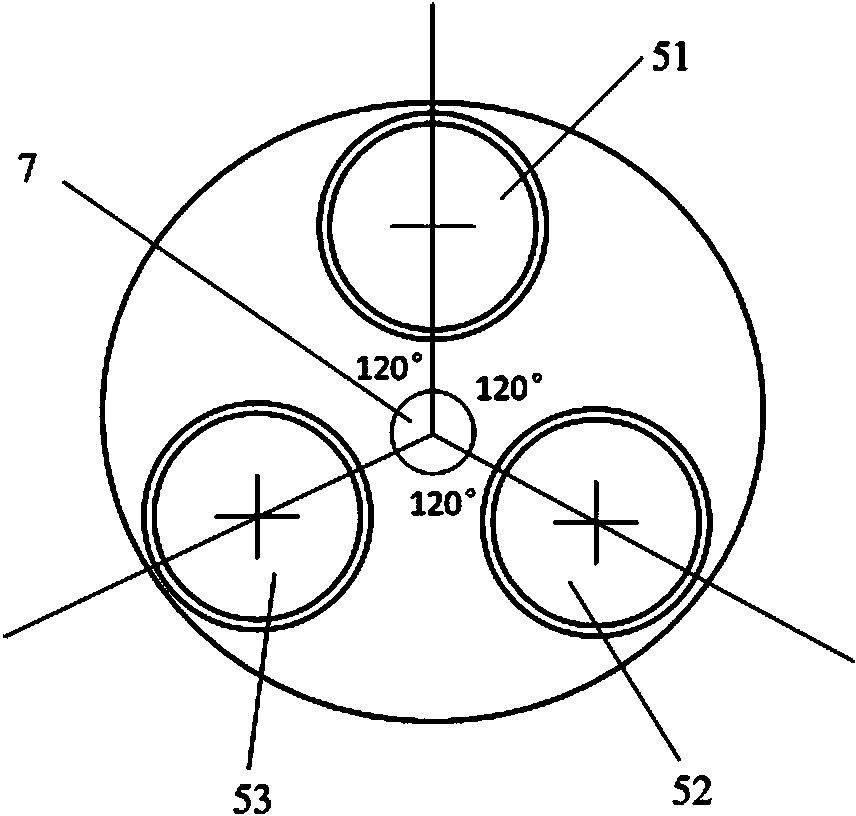

[0068] Such as figure 1 As shown, the detection host includes a catadioptric optical collimation system 100 , a multi-band target plate and a target light source 200 , a CCD aiming module 300 , a wireless video transmitting module 12 and a power supply 13 .

[0069] The catadioptric optical collimation system 100 includes a primary mirror 1 , a secondary mirror 2 , a mirror 3 and an attenuation sheet group 4 . The primary mirror 1 is an off-axis parabolic mirror; the secondary mirror 2 is an off-axis high-order hyperboloid mirror; the mirror 3 deflects the main optical path light, making the main structure of the catadioptric optical collimation...

Embodiment 2

[0077] Embodiment 2: A method for detecting consistency of multiple optical axes of a platform photoelectric instrument.

[0078] The detection method is based on non-cooperative targets and image processing technology, and the specific steps are as follows:

[0079] combine Figure 1 ~ Figure 4 , the optoelectronic instrument of the platform measured in the present invention is composed of a visible light sighting system (including low light), an infrared imaging system and a laser emitting module.

[0080]First, aim the photoelectric instrument of the platform under test at a fixed non-cooperative target at the infinite field of view, place the detection host 20 in the optical path of the laser emission module, and use the support mechanism to erect the detection host 20 . The process of setting up the detection host 20 is: according to the actual installation position of the photoelectric instrument of the platform to be tested, the length of the connecting pipe assembly 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com