Gas sensor based on mesoporous indium oxide gas-sensitive material and preparation method

A technology of gas sensor and gas-sensitive material, which is applied in the field of gas sensor with high gas-sensitivity performance, and can solve problems such as incompatibility with high gas-sensitivity and high selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

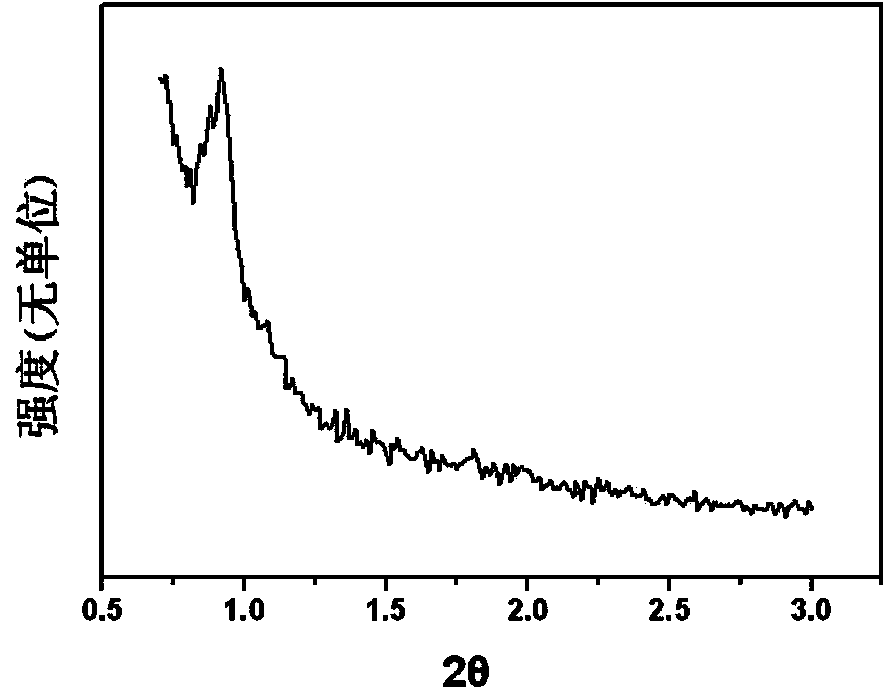

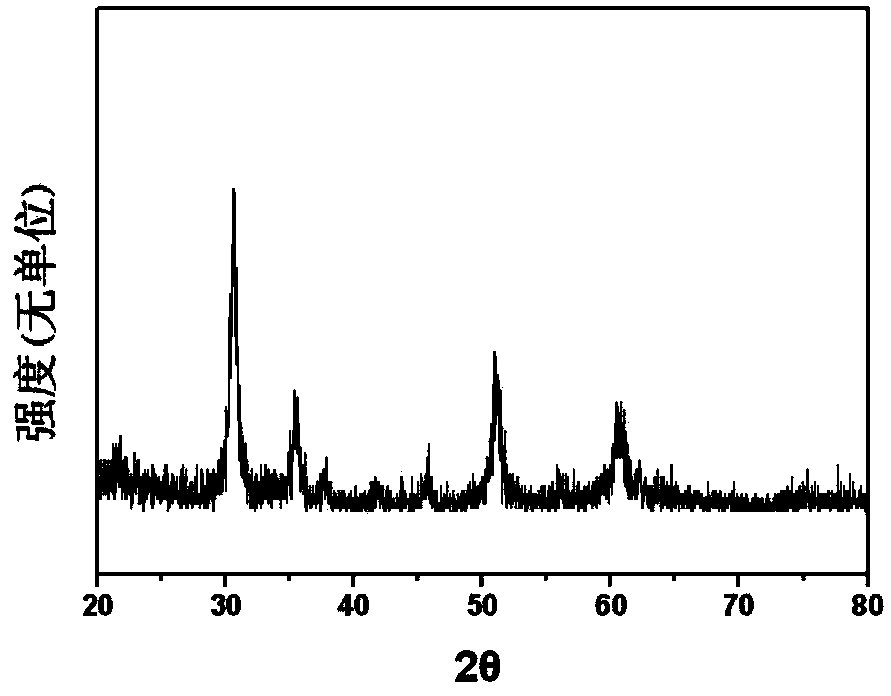

[0018] Example 1: Using ordered mesoporous silicon oxide SBA-15 as a hard template, the mass ratio of it to the precursor of indium nitrate pentahydrate is 100, and the room temperature ethanol impregnation method makes the indium precursor immersed in the silicon oxide mesoporous channel, and then The ethanol solvent was evaporated, and the obtained calcined mixture was loaded into a crucible with a ratio of the opening area of the container to the sample volume of the calcined mixture of 10-6 for calcination, the calcination temperature was 200°C, and the holding time was 20h. Then, the silicon oxide template is removed by centrifugation after stirring with sodium hydroxide solution, and an ordered mesoporous indium oxide material is obtained.

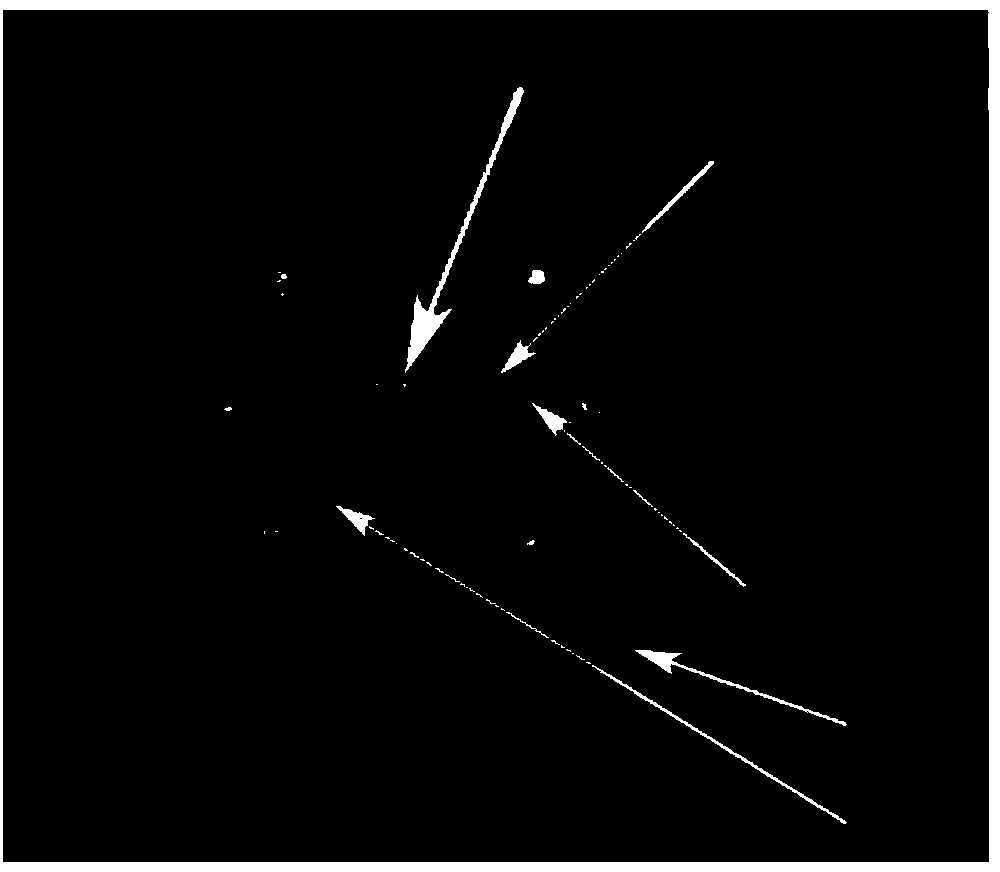

[0019] like figure 1 A schematic diagram of the fabricated sensor and its sensing layer is shown in . Prepare a mesoporous indium oxide coating slurry with a concentration of 0.1g / mL, and use a paint pen to evenly coat the slurry ...

Embodiment 2

[0020] Example 2: Using ordered mesoporous silicon oxide MCM-41 as a hard template, the mass ratio of it to the precursor of indium nitrate pentahydrate is 10, and the indium precursor is immersed in the silicon oxide mesoporous channel by the room temperature ethanol impregnation method, and then The ethanol solvent was evaporated, and the obtained calcined mixture was loaded into a crucible with a ratio of the opening area of the container to the sample volume of the calcined mixture to be calcined at 400° C. for 5 hours. Then, the silicon oxide template is removed by centrifugation after stirring with sodium hydroxide solution, and an ordered mesoporous indium oxide material is obtained.

[0021] Prepare the mesoporous indium oxide coating slurry with a concentration of 0.2g / mL, and use a paint pen to evenly coat the slurry on the outer surface of the ceramic core with gold electrodes to form an indium oxide sensing layer with a thickness of 300um. After the coating is co...

Embodiment 3

[0022] Example 3: Using ordered mesoporous silicon oxide KIT-6 as a hard template, the mass ratio of it to the precursor of indium nitrate pentahydrate is 0.1, and the indium precursor is immersed in the silicon oxide mesoporous channel by the room temperature ethanol impregnation method, and then Evaporate ethanol solvent, and the calcined mixture that obtains is packed into the ratio of container opening area and calcined mixture sample amount is 10 -4 Calcined in a crucible, the calcination temperature is 800 ℃, and the holding time is 0.2h. Then, the silicon oxide template is removed by centrifugation after stirring with sodium hydroxide solution, and an ordered mesoporous indium oxide material is obtained.

[0023] Prepare a mesoporous indium oxide coating slurry with a concentration of 0.02g / mL, and use a paint pen to evenly coat the slurry on the outer surface of a ceramic tube core with a gold electrode to form an indium oxide sensing layer with a thickness of 500nm. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com