Longitudinally-sealed underwater cable manufacturing method

A manufacturing method and optical cable technology, applied in the direction of fiber mechanical structure, etc., can solve the problems of complex underwater optical cable structure, poor longitudinal water tightness, high manufacturing cost, etc., achieve simple structure, good longitudinal water tightness, and improve product quality and reliability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

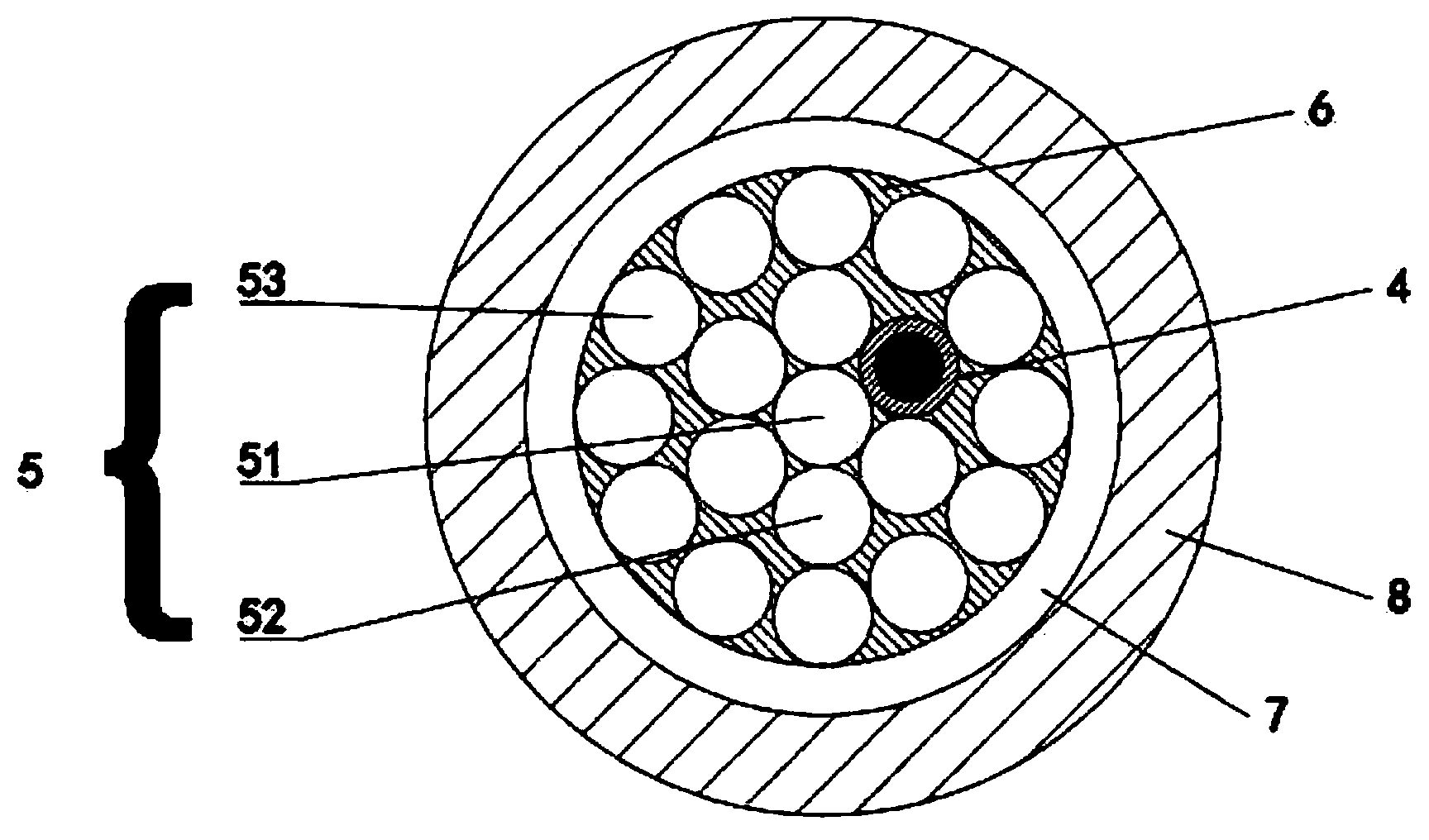

[0033] Fiber optic cable contains:

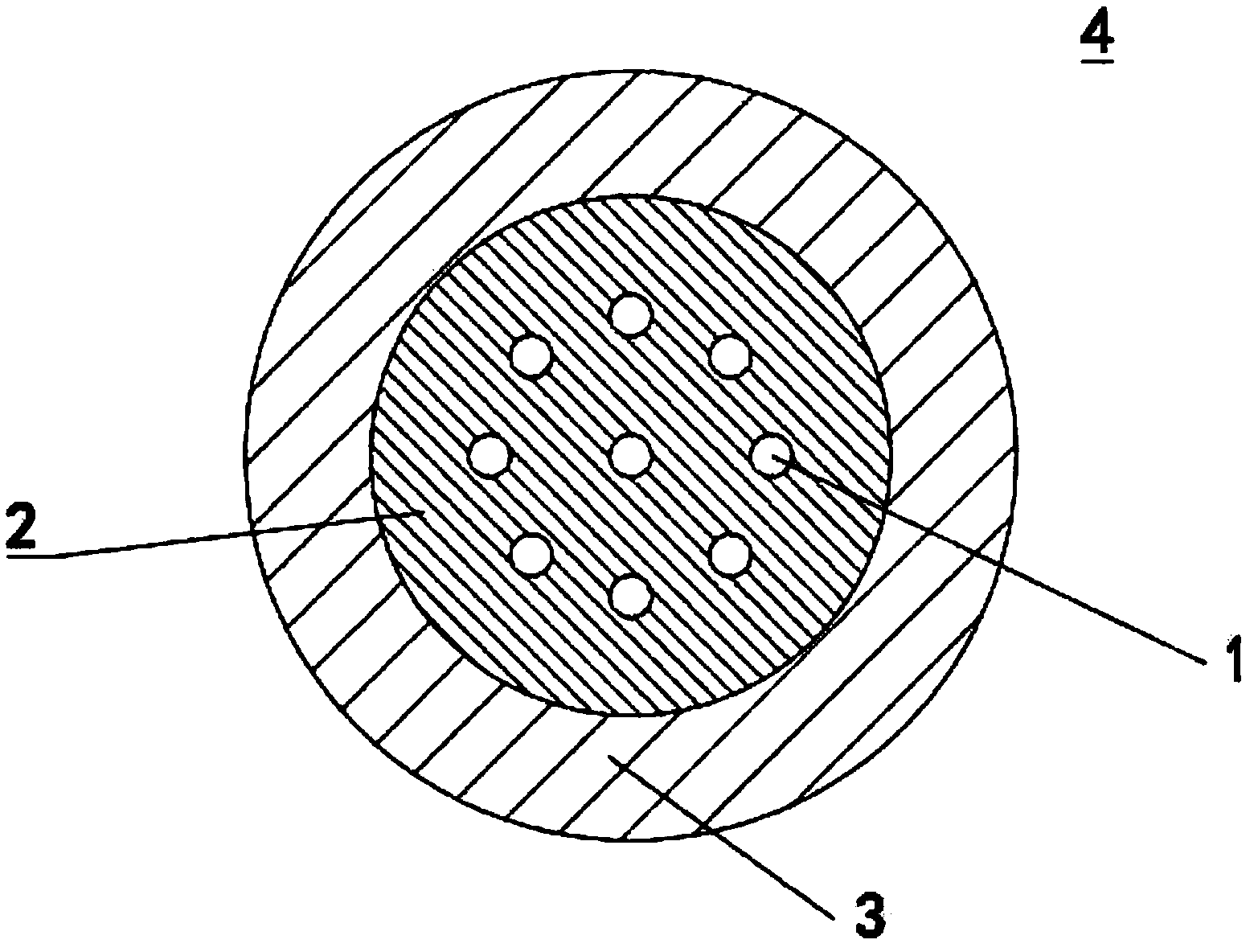

[0034] 2 optical units 4, each optical unit 4 contains: 24 optical fibers 1, hydrogen-absorbing fiber paste 2, stainless steel tube 3 with a diameter of 3 mm;

[0035] The middle line 51 is: a steel wire with a diameter of 3mm;

[0036] The strengthening device 52 between optical units includes: 4 steel wires with a diameter of 3mm;

[0037] The external strengthening device 53 of the light unit includes: 12 steel wires with a diameter of 3mm;

[0038] The water-blocking and anti-corrosion material 6 is made of hot melt adhesive;

[0039] The waterproof sheath includes: wrapping tape 7, polyurethane sheath 8.

[0040] The preparation method comprises the following steps:

[0041] The first step is to wrap the optical fiber 1 and the hydrogen-absorbing fiber paste 2 inside the stainless steel tube 3 by conventional techniques to make the optical unit 4 .

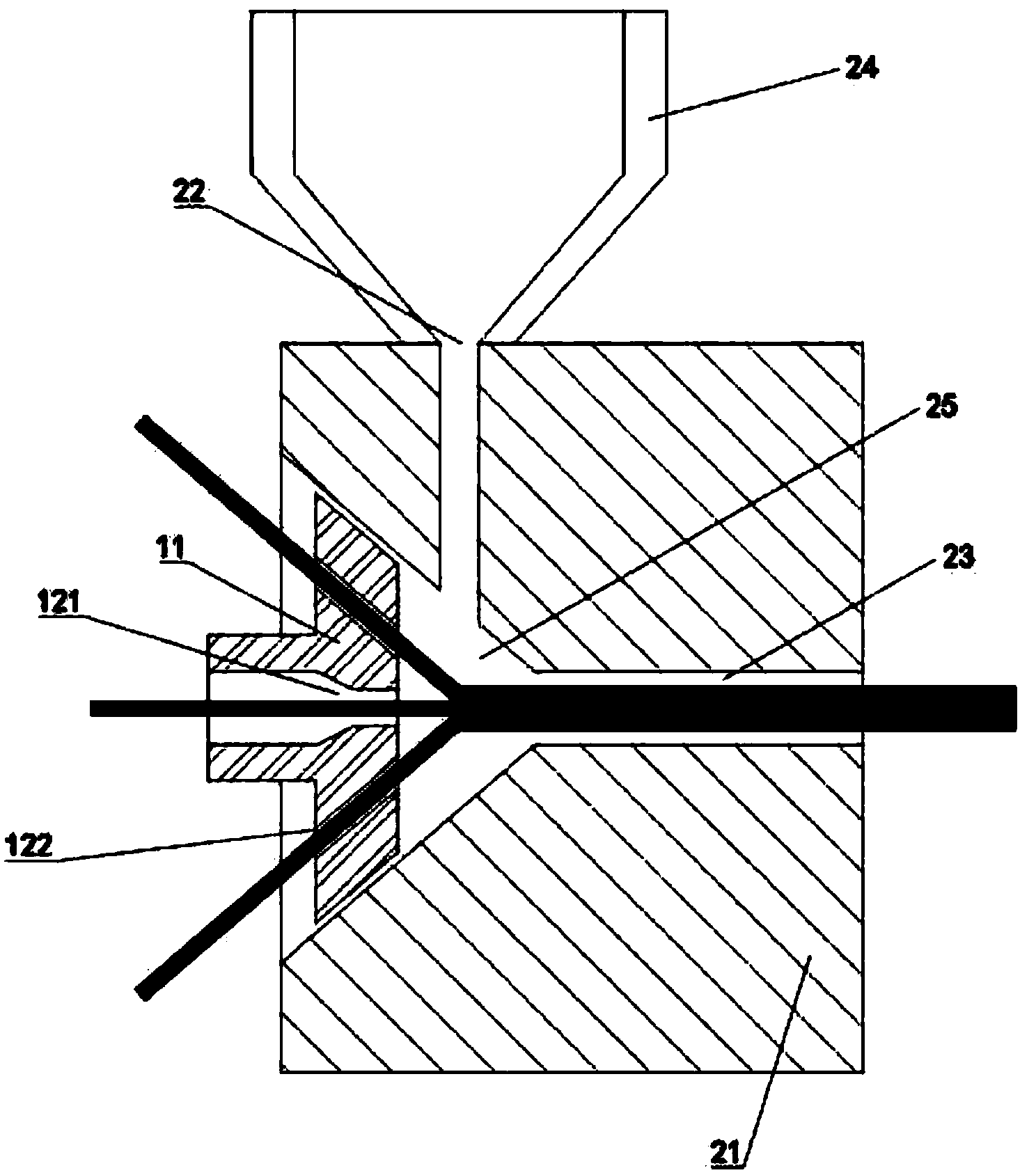

[0042] The second step is to melt the hot melt adhesive and keep it at a constant...

Embodiment 2

[0056] Fiber optic cable contains:

[0057] 1 optical unit 4, each optical unit 1 contains: 12 optical fibers 1, hydrogen-absorbing fiber paste 2, stainless steel tube 3 with a diameter of 2.8 mm;

[0058] The middle line 51 is: a steel wire with a diameter of 2.8mm;

[0059] The strengthening device 52 between optical units includes: 5 steel wires with a diameter of 2.8 mm;

[0060] The water-blocking and anti-corrosion material 6 is made of hot melt adhesive;

[0061] The waterproof sheath includes: wrapping tape 7, polyethylene sheath 8.

[0062] Repeat the preparation method of Embodiment 1 in combination with the rotating mold, except that there is no external reinforcing device 53 for the light unit in this embodiment, so the sixth step above is omitted. The preparation method comprises the following steps:

[0063] The first step is to prefabricate the light unit;

[0064] In the second step, the hot melt adhesive is melted in the constant temperature heating devic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap