System comprising an electrically excited machine

A technology of excitation winding and potential, applied in the field of operating the system according to the present invention, can solve the problem that the battery system does not provide a constant DC voltage and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

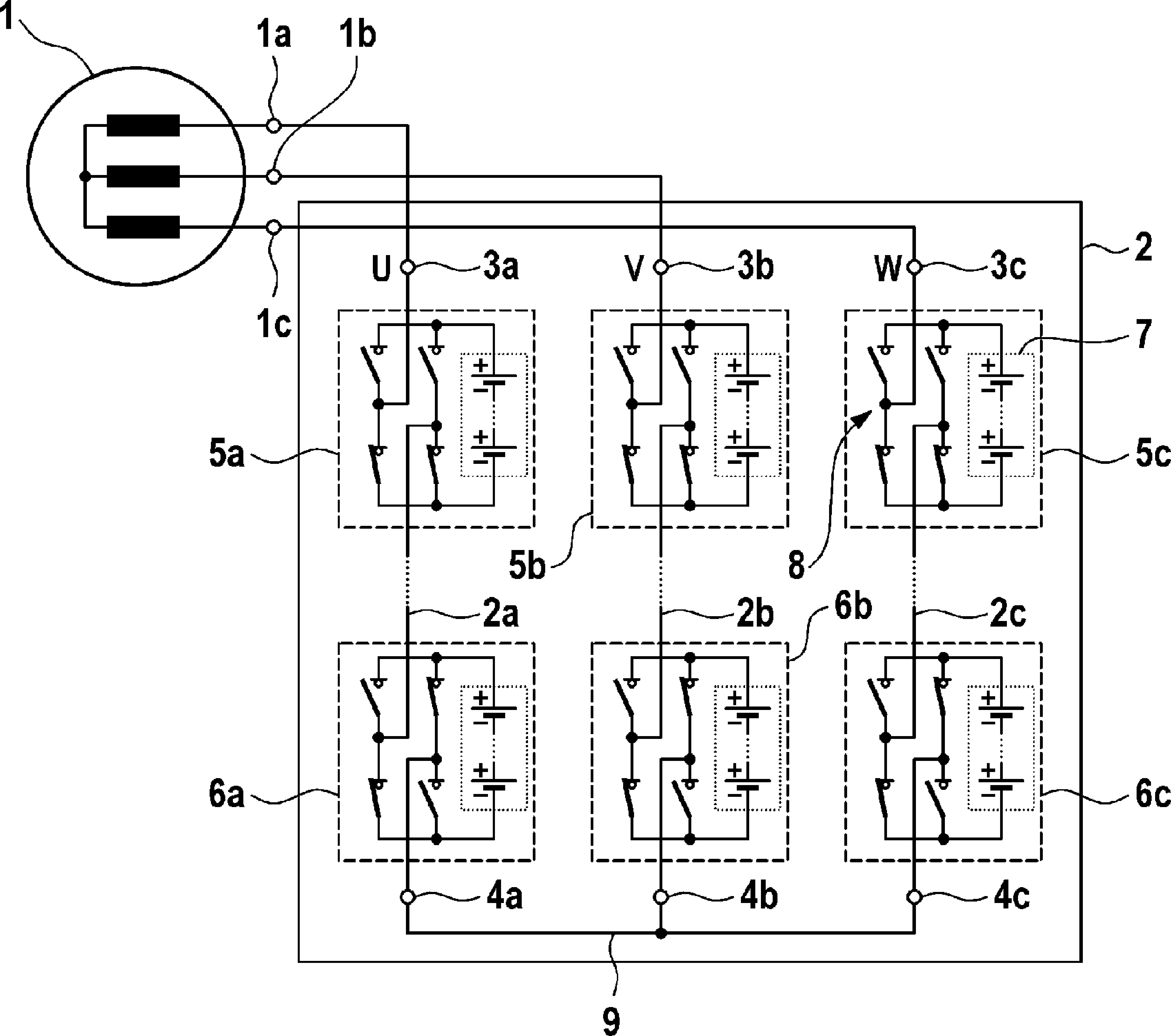

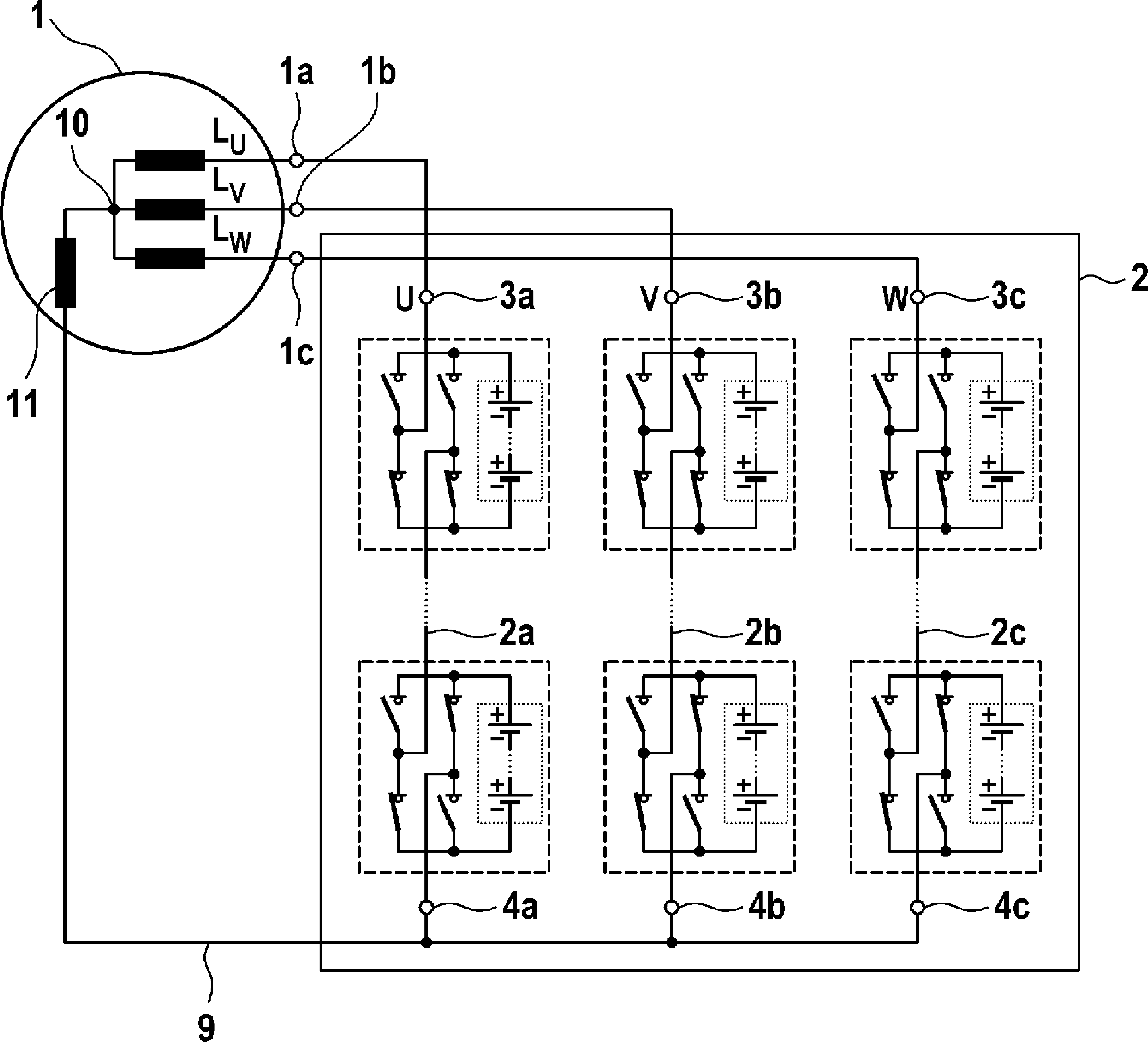

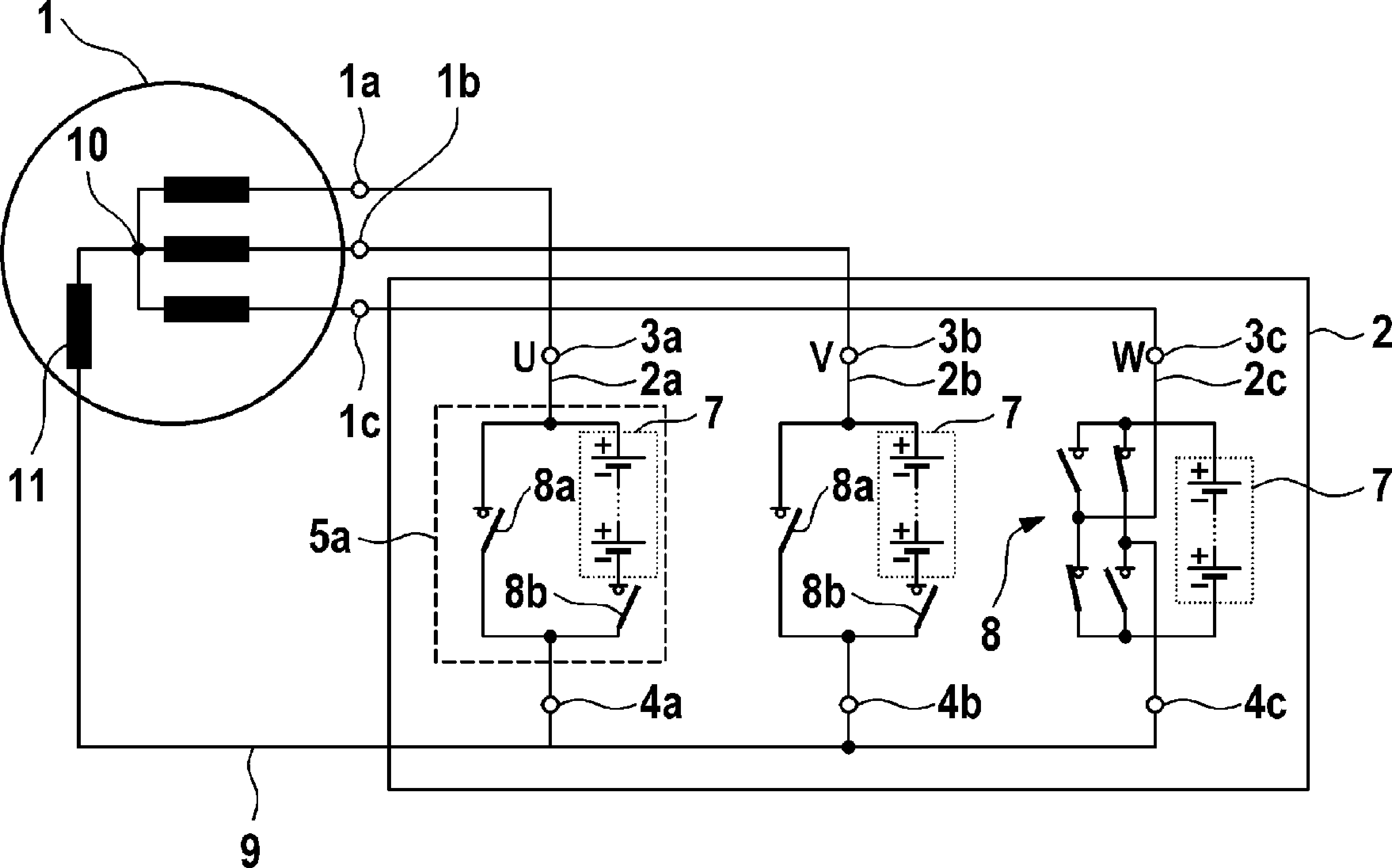

[0017] figure 2 A system with an electric machine 1 and a controllable energy store 2 is shown. The electric machine 1 is shown by way of example as a three-phase electric machine 1 , which is supplied with energy via a first controllable energy store 2 . The first controllable energy store 2 comprises three energy supply branches 2a, 2b, 2c, which are connected on one side via terminals 4a, 4b, 4c to a reference potential 9 (reference busbar), said reference In the embodiment shown, the potential 9 conducts an average potential with respect to the phases U, V, W of the electric machine 1 , and the energy supply branches are connected on the other side to the respective phases U, V, W of the electric machine 1 . In this case, the terminal 3a of the first energy supply branch 2a is coupled to the first phase terminal 1a of the electric machine 1, the terminal 3b of the second energy supply branch 2b is coupled to the second phase terminal 1b of the electric machine 1, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com