Single-polymer composite product melt-coating roll forming method and equipment

A composite material and roll forming technology, applied in the field of polymer composite material forming and processing, can solve the problems of incapable of continuous production, long forming cycle, small product size, etc., and achieve the effects of low density, high production efficiency and easy operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

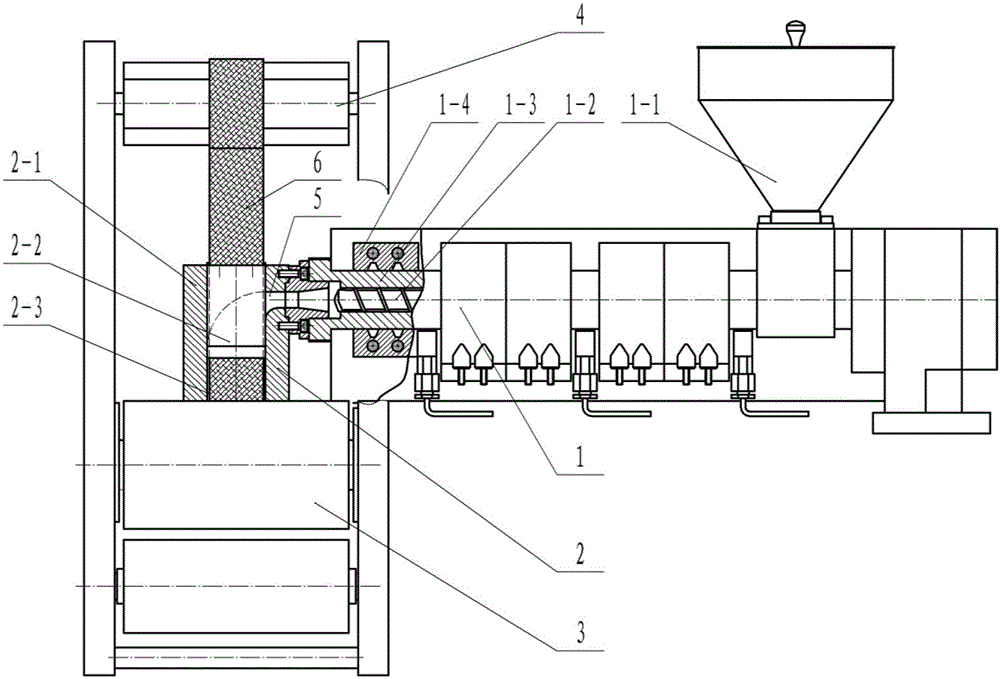

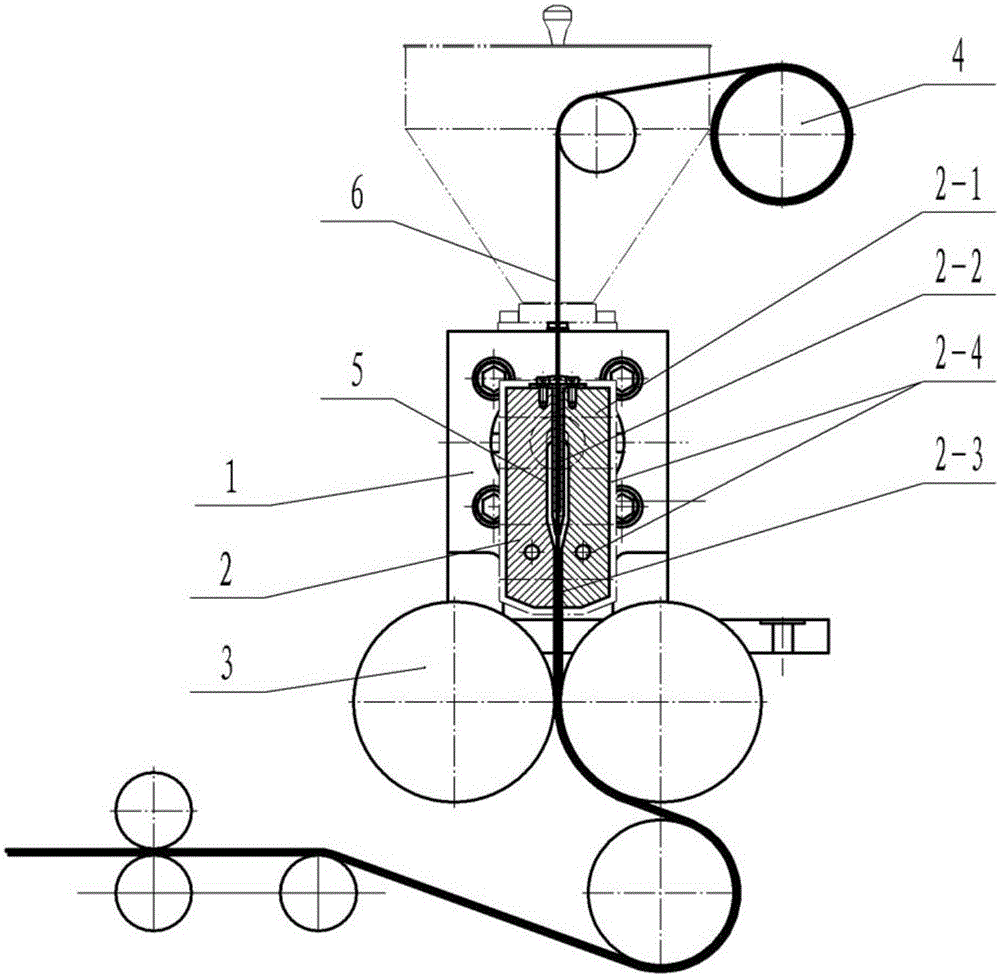

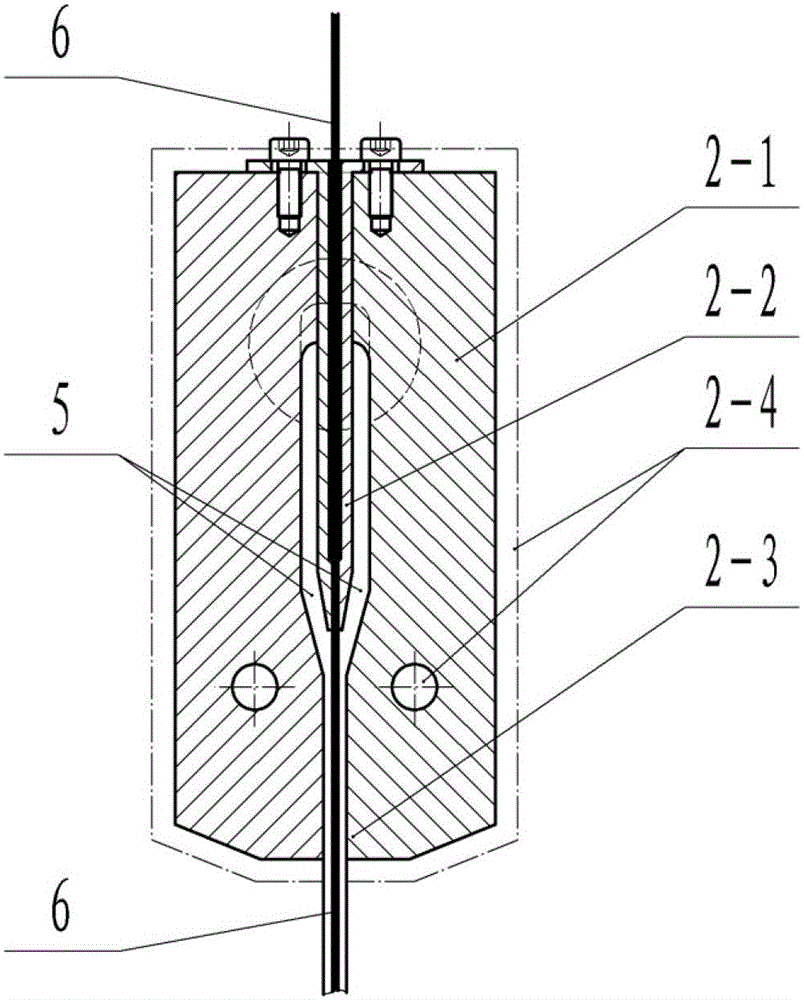

[0041] A single-polymer composite material product melt-coating roll forming equipment, the equipment is composed of an extruder (1), a machine head (2), a roller press (3) and a traction device (4), the extruder (1) It is mainly composed of hopper (1-1), screw (1-2), barrel (1-3), heating and cooling system I (1-4), and the machine head (2) is mainly composed of machine head body (2 -1), distribution pipe (2-2), die (2-3), heating and cooling system II (2-4), characterized in that: the outer wall or / and wall of the barrel (1-3) There is a heating and cooling system I (1-4), the screw (1-2) is inside the barrel (1-3), the hopper (1-1) is at the rear end of the barrel (1-3); the barrel ( 1-3) The front section is fixedly connected with the rear end of the machine head body (2-1), the shunt pipe (2-2) is set inside the machine head body (2-1), and the die (2-3) is set in the machine head body (2-1) front end, heating and cooling system II (2-4) is set in the outer wall or / and w...

Embodiment 2

[0051] The difference from Example 1 is that the machine head (2) is designed according to a plate product with a thickness of 6 mm and a width of 40 mm; the shunt pipe (2-2) has three tube holes, all of which are rectangular holes with a length of 38 mm and a width of 1 mm. The reinforcement adopts three layers of fiber tapes with a thickness of 1mm and a width of 38mm, which can pass through the three pipe holes of the middle shunt pipe (2-2) through traction; the outlet hole of the die (2-3) is 40mm long and 7mm wide The two rollers of the roller press (3) are set at the front end of the die (2-3), and the gap between the two rollers is 6mm, so that a single polymer compound with a thickness of 6mm and a width of 40mm can be finally formed. Material sheet products.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com