Axle box, bogie, railway machine and axle box suspension device of bogie of railway machine

A bogie shaft and suspension device technology, which is applied in the field of bogies, can solve the problems of increasing the amount of wheel repair and track maintenance, easy deviation in mutual cooperation, hard impact of the car body, etc., and achieves good running stability and smoothness. Reduce the amount of track maintenance, ease the effect of good vibration damping performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The content of the present invention will be described below in conjunction with the accompanying drawings. The following description is only exemplary and explanatory, and should not have any limiting effect on the protection scope of the present invention.

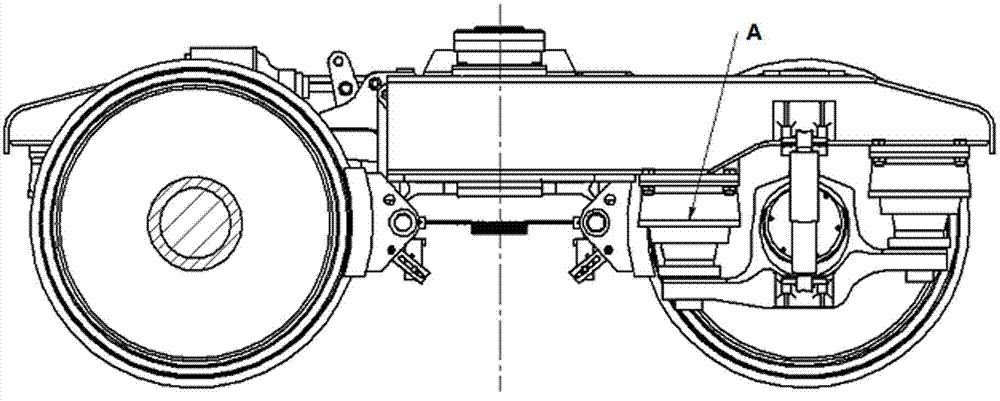

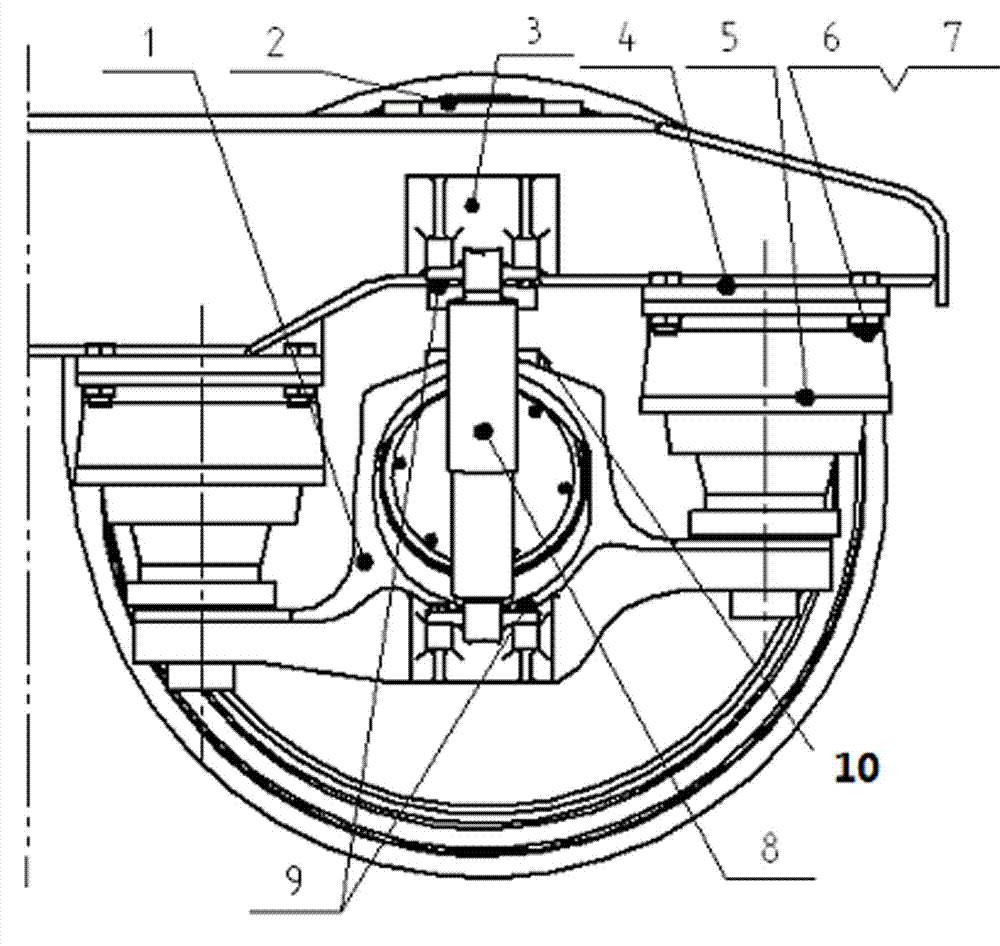

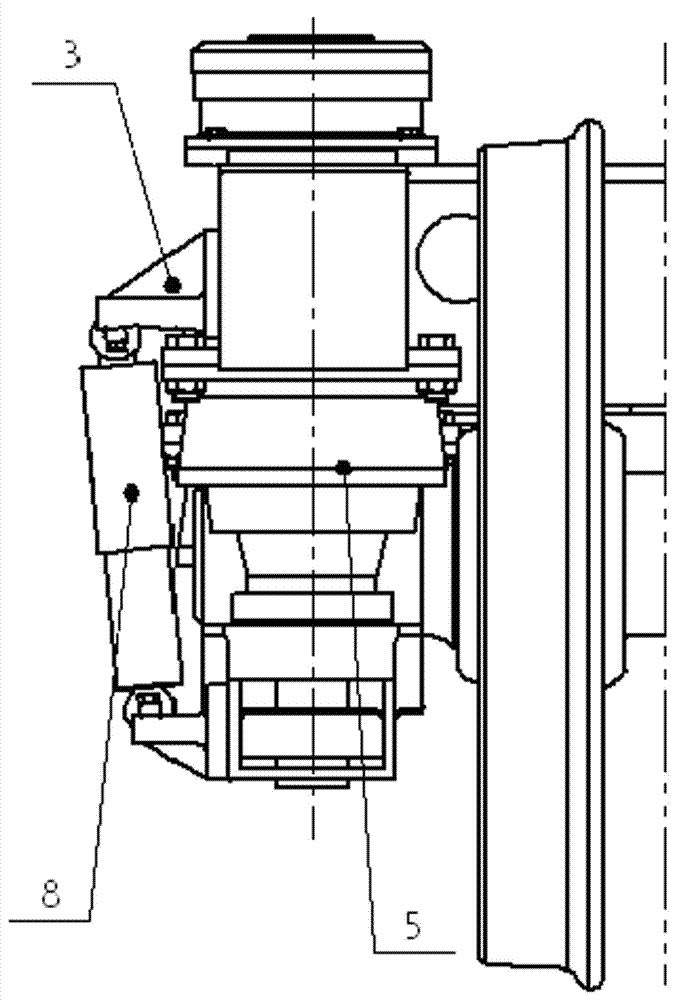

[0031] A railway machinery bogie axle box suspension device (A), such as figure 1 As shown, it is set between the railway vehicle bogie frame and the wheel set, such as figure 2 , image 3 As shown, it includes an axle box (1), a metal rubber spring (5), a vertical oil pressure shock absorber (8), a bogie frame, and a metal rubber spring mounting seat (4) arranged on the bogie frame , The vertical oil pressure shock absorber installation seat (3) set on the bogie frame, the shaft support oil cylinder (2), the axle box (1) is installed on the axle box bearing of the railway vehicle wheel set, and the metal rubber spring (5) One end is installed on the axle box (1), and the other end is connected with the metal r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com