Hydrophobic surface, preparation method and application thereof in dropwise condensation heat transfer

A hydrophobic surface, drop-like condensation technology, applied in the application of hydrophobic surface, drop-like condensation heat transfer, preparation field, to achieve the effect of simple process, low cost, accelerated merging and shedding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] In the preparation method of the above-mentioned hydrophobic surface, the hydrophobic surface is directly constructed on the surface of the substrate, or the prepared hydrophobic flexible film with a micro-nano two-level structure is fixed on the surface of the substrate. The construction methods of surface micro-nano two-level structure include but not limited to spin-coating, photolithography, electrolysis and other micro-nano structure processing methods. details as follows:

[0031] 1) Fabricate a photoresist insulation shielding film with a grid line pattern on the surface of the metal sample by combining spin coating and photolithography, and grind the surface of the metal sample to make the surface smooth;

[0032] 2) After step 1), use the metal sample (metal surface) as the electrolysis anode, turn on the power, and carry out electrolysis;

[0033] 3) After the electrolysis is finished, turn off the power first, then take the metal sample out of the holding de...

Embodiment 1

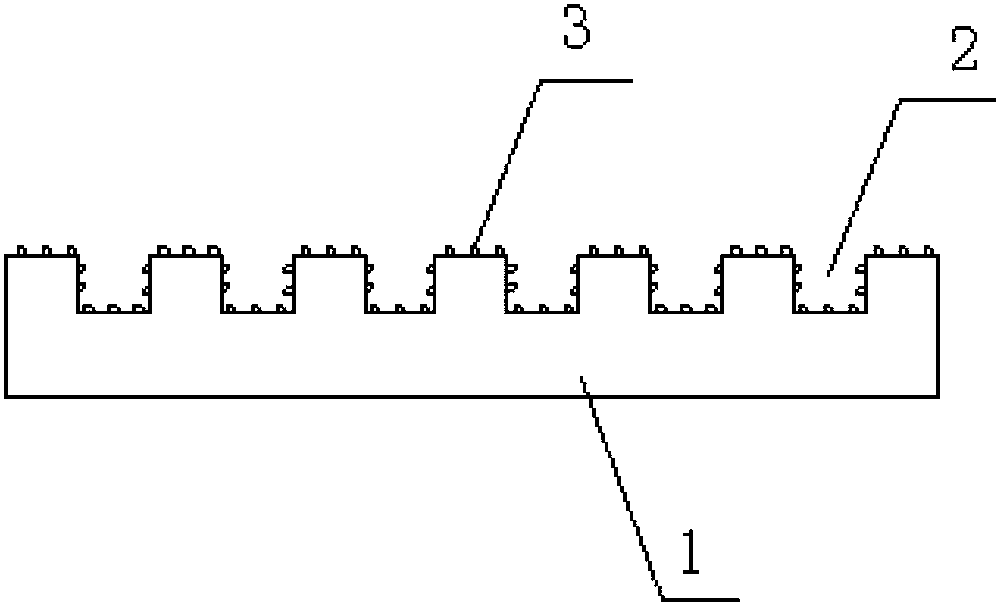

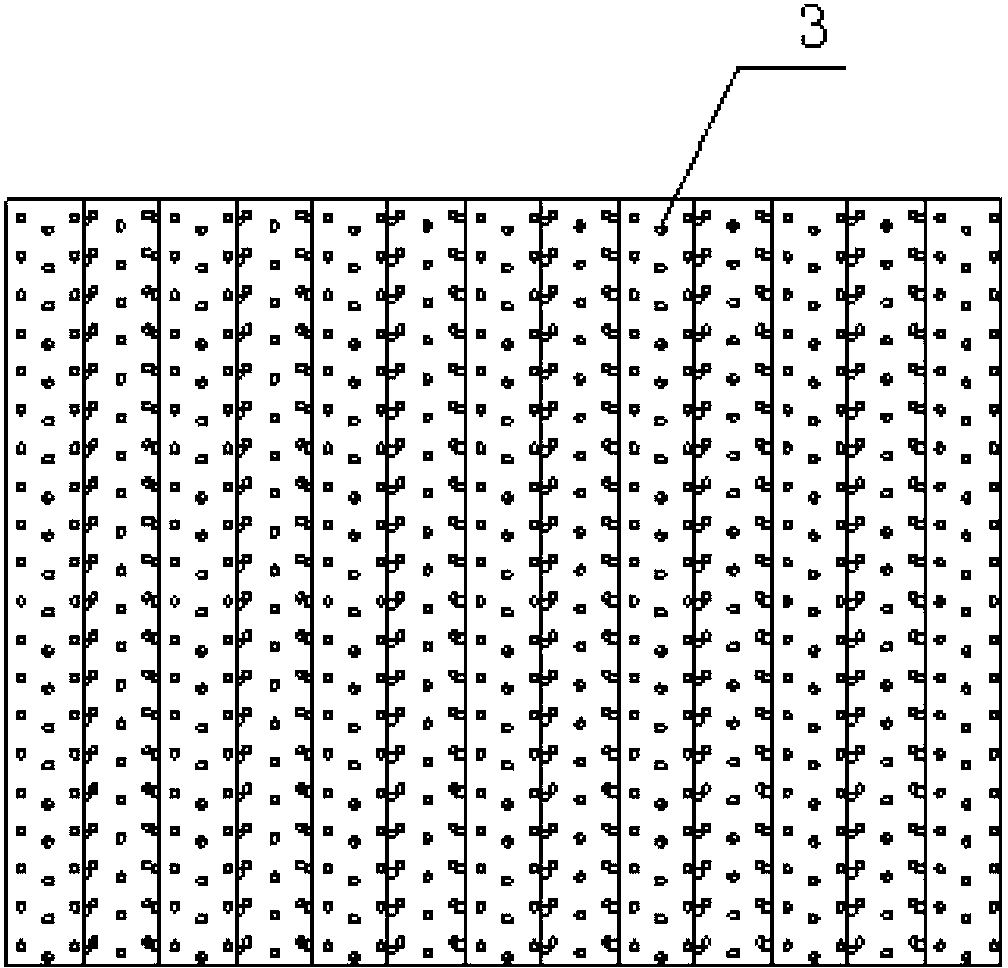

[0039] refer to figure 1 and figure 2 , the overall shape of the micro-nano two-level structure constructed on the surface of the substrate by the hydrophobic surface is mainly a grid-shaped structure; the size of the strip-shaped protrusions and grooves in the grid-shaped structure is micron, and the random columnar array spread over it is nanometer level structure. The direction of the grid lines is consistent with the direction of gravity during the condensation heat transfer process.

[0040] Based on the integral model of droplet condensation heat conduction established by Rose, taking the maximum diameter of droplet in the condensation process of each surface as the main comparison index, the anisotropic micro-nano structure hydrophobic surface prepared by the present invention and the existing non-anisotropic micro-nano structure hydrophobic The heat flux of the surface and nano-structured hydrophobic surface was calculated, and the results proved that the heat flux ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com