Suspended filler limit denitrification method and suspended filler limit denitrification system

A technology of suspended filler and denitrification, which is applied in chemical instruments and methods, water treatment parameter control, special compound water treatment, etc. Clogging and other problems, to achieve the effect of simple composition, large processing flexibility, and improved utilization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

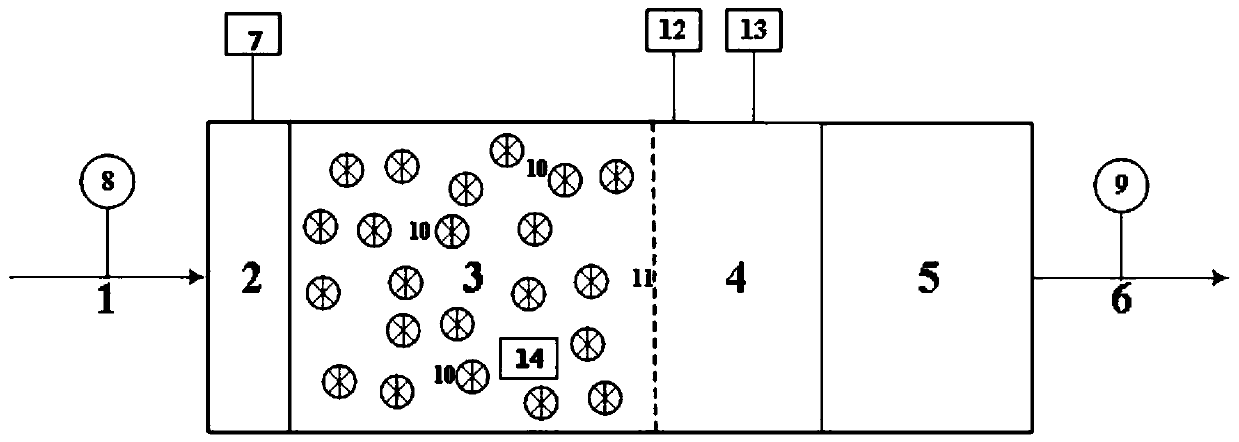

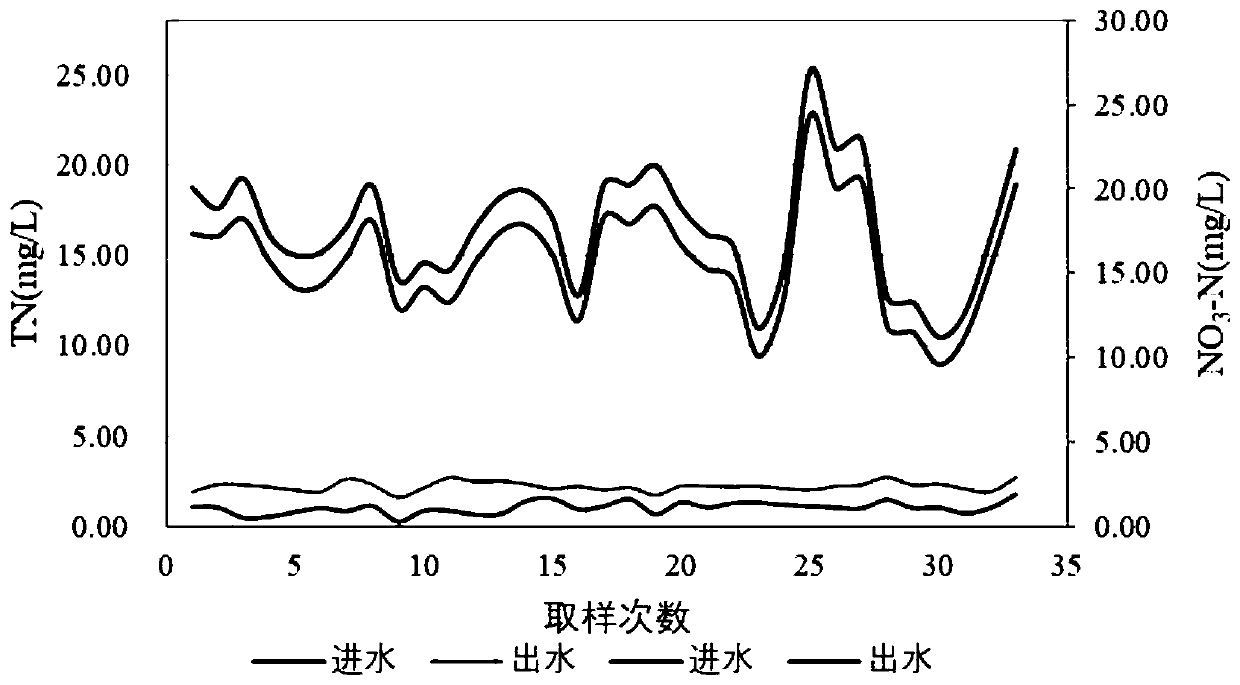

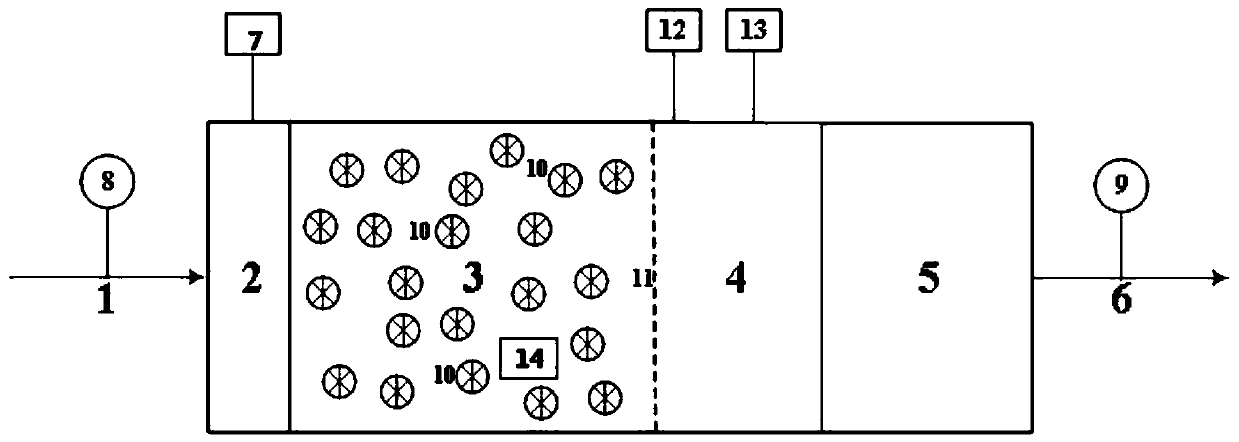

[0023] Such as figure 1 Shown: a suspended packing limit denitrification system, the system is placed behind the secondary settling tank unit and directly connected with the secondary settling tank unit. The system is composed of water inlet and distribution area 2, denitrification reaction area 3, flocculation reaction area 4 and sedimentation area 5 connected in sequence. The water inlet and distribution area is connected to the carbon source automatic control system 7 . Suspended filler 10 is added to the denitrification reaction zone, and a denitrification biofilm is attached to the surface of the suspended filler; flocculant dosing points and coagulant aid dosing points are set on the flocculation reaction zone. The system efficiently removes nitrate nitrogen in tap water under the condition of adding carbon source. According to the water quality and denitrification requirements, the proportion of suspended fillers in the denitrification reaction zone can be flexibly ad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com