Preparation method of supercapacitor cobaltous oxide electrode material

A technology for supercapacitors and electrode materials, which is applied in the fields of electrochemical science and energy, can solve problems such as limiting capacitance performance, and achieve the effects of stable working window, low manufacturing cost, and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

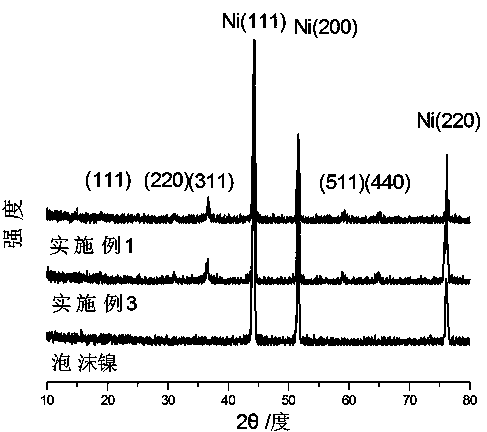

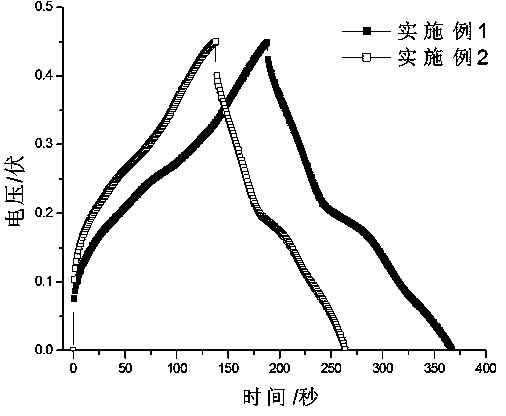

[0038] Example 1: Using absolute ethanol as a solvent to prepare a cobalt oxide electrode and evaluate its capacitance performance

[0039] Cobalt nitrate and cetyltrimethylammonium bromide are mixed according to the mass ratio of 10:1, dissolved in 15ml of absolute ethanol; the solution is poured into a reaction kettle with a capacity of 25ml, and simultaneously in the reaction kettle Put in the foamed nickel substrate; put the reactor into a constant temperature oven at a temperature of 160°C, and the solvent heating time is 24 hours; after the solvent thermal reaction is completed, take out the black foamed nickel electrode from the reactor and rinse it with deionized water Clean; dry the cleaned electrode in a constant temperature oven at a temperature of 80°C for 6 hours to obtain a cobalt oxide electrode.

[0040]The cobalt oxide electrode was electrochemically tested, and the prepared cobalt oxide electrode was used as the working electrode, the saturated calomel electr...

Embodiment 2

[0041] Embodiment 2: Change the solvothermal time to the evaluation of the capacitive performance of cobalt oxide electrode

[0042] According to the preparation process of Example 1, cobalt nitrate and cetyltrimethylammonium bromide are in a mass ratio of 10:1, using absolute ethanol as a solvent, the temperature is 160 ° C, and the solvent heating time is 12 hours, and the same can be A cobalt oxide electrode was prepared. With 5mol / L KOH aqueous solution as the electrolyte, when the current density is 2A / g, the specific capacitance reaches 595.11F / g.

Embodiment 3

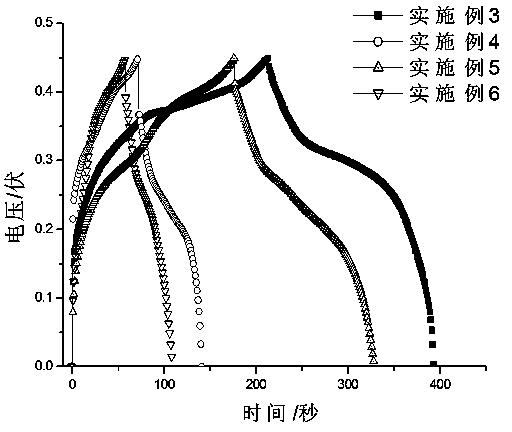

[0043] Example 3: Preparation of Cobalt Oxide Electrode and Evaluation of Capacitance Performance Using Isopropanol as Solvent

[0044] The solvent in the preparation process of Example 1 was replaced by isopropanol instead of absolute ethanol as the solvent, cobalt nitrate and cetyltrimethylammonium bromide in a mass ratio of 10:1, the temperature was 160°C, and the time For 24 hours, a cobalt oxide electrode was prepared. With 5mol / L KOH aqueous solution as the electrolyte, when the current density is 2A / g, the specific capacitance reaches 857.5F / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Current density | aaaaa | aaaaa |

| Specific capacitance | aaaaa | aaaaa |

| Specific capacitance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com