A treatment, regeneration and cyclic utilization method for tobacco sheet production wastewater

A technology for the production of waste water and tobacco flakes, which is applied in the fields of water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc. and other problems to achieve high activity and prevent scaling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

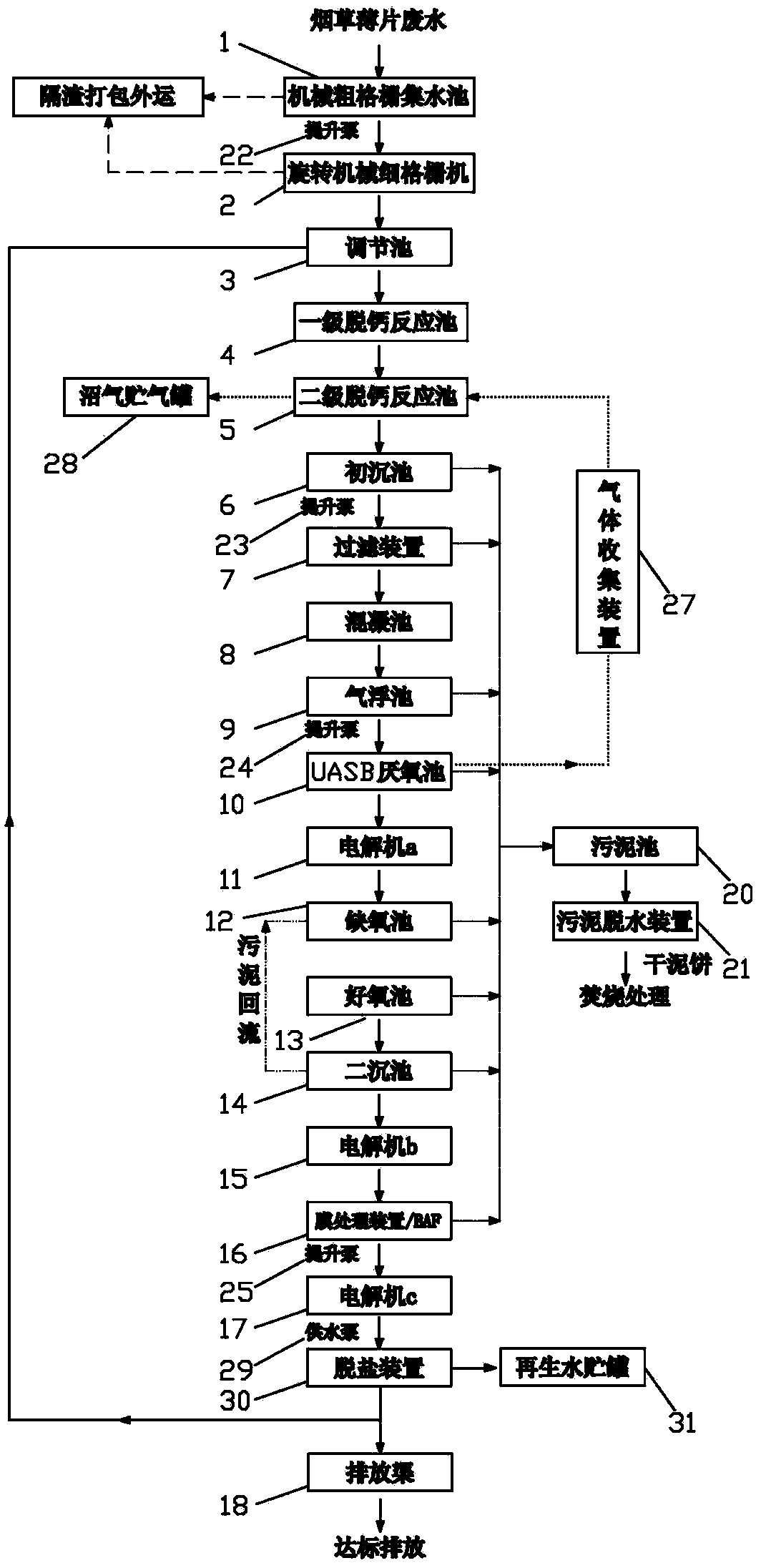

Image

Examples

Embodiment 1

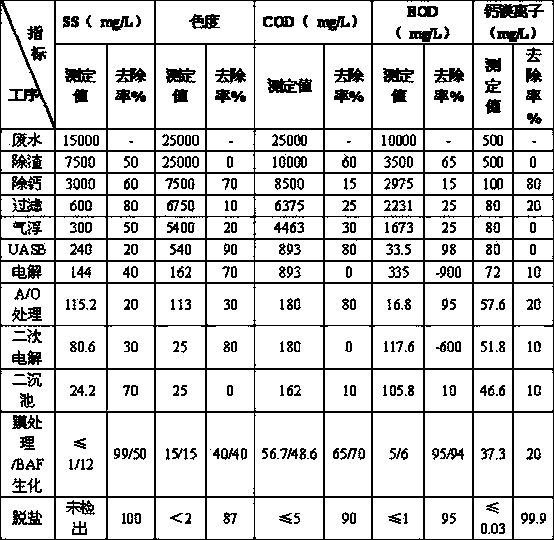

[0056] 20 tons / day tobacco flake production wastewater treatment and recycling method.

[0057] Table 2 shows the water quality indicators of the tobacco sheet production wastewater after determination.

[0058] serial number project unit measured value serial number project unit measured value 1 COD Cr mg / L 25000 5 Chroma times 25000 2 BOD 5 mg / L 6000 6 Ca 2+ mg / L 500 3 SS mg / L 15000 7 water temperature ℃ 50 4 pH value —— 5.5

[0059] (1) Slag removal

[0060] Wastewater from tobacco flake production is collected by pipelines and then discharged into mechanical coarse grid pool 1. Coarse grids are set in the pool to isolate and remove medium and coarse floating objects in the sewage to prevent subsequent processing equipment from clogging, and then through the lifting pump 22, Elevate the waste water from tobacco flake production to the rotary mechanical fine grid machine 2, and furt...

Embodiment 2

[0087] A method for the treatment and recycling of 50 tons / day tobacco flake production wastewater.

[0088] The water quality indicators of the tobacco sheet production wastewater were determined and shown in Table 5.

[0089] serial number project unit measured value serial number project unit measured value 1 COD Cr mg / L 9000 5 Chroma times 12000 2 BOD 5 mg / L 3000 6 Ca 2+ mg / L 300 3 SS mg / L 5000 7 water temperature ℃ 65 4 pH value —— 6.2

[0090] (1) Slag removal

[0091] Wastewater from tobacco flake production is collected by pipelines and then discharged into mechanical coarse grid pool 1. Coarse grids are set in the pool to isolate and remove medium and coarse floating objects in the sewage to prevent subsequent processing equipment from clogging, and then through the lifting pump 22, Elevate the waste water from tobacco flake production to the rotary mechanical fine grid machi...

Embodiment 3

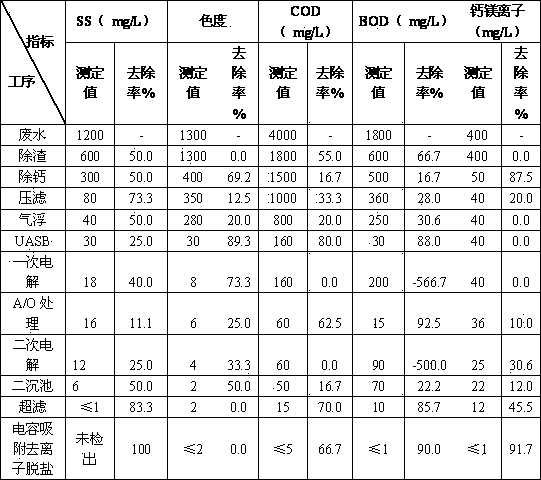

[0118] 10 tons / day tobacco flake production wastewater treatment and recycling method.

[0119] The water quality indicators of the tobacco sheet production wastewater were determined as shown in Table 8.

[0120] serial number project unit measured value serial number project unit measured value 1 COD C mg / L 4000 5 Chroma times 1300 2 BOD 5r mg / L 1800 6 Ca 2+ mg / L 400 3 SS mg / L 1200 7 water temperature ℃ 50 4 pH value —— 6.5

[0121] (1) Slag removal

[0122] Wastewater from tobacco flake production is collected by pipelines and then discharged into mechanical coarse grid pool 1. Coarse grids are set in the pool to isolate and remove medium and coarse floating objects in the sewage to prevent subsequent processing equipment from clogging, and then through the lifting pump 22, Elevate the waste water from tobacco flake production to the rotary mechanical fine grid machine 2, and furth...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Current density | aaaaa | aaaaa |

| Current density | aaaaa | aaaaa |

| Current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com