A method for cutting tempered glass

A technology of strengthening glass and cutting method, applied in glass cutting device, glass production, glass manufacturing equipment and other directions, can solve the problems of inability to strengthen glass cutting, limited production capacity, high processing cost, etc., to increase output, reduce manufacturing cost, The effect of increasing process efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

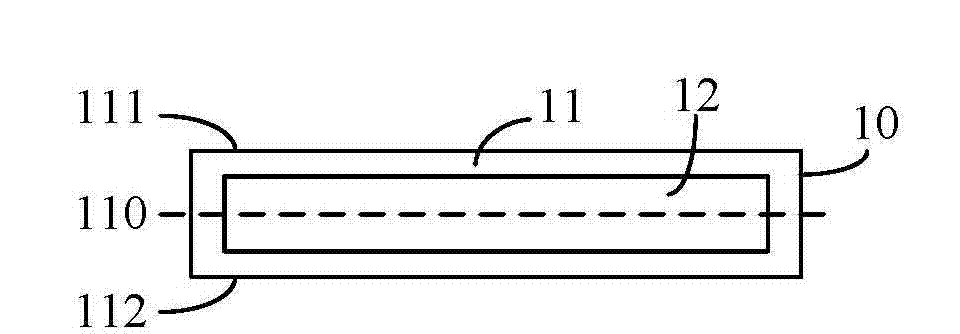

Embodiment 1

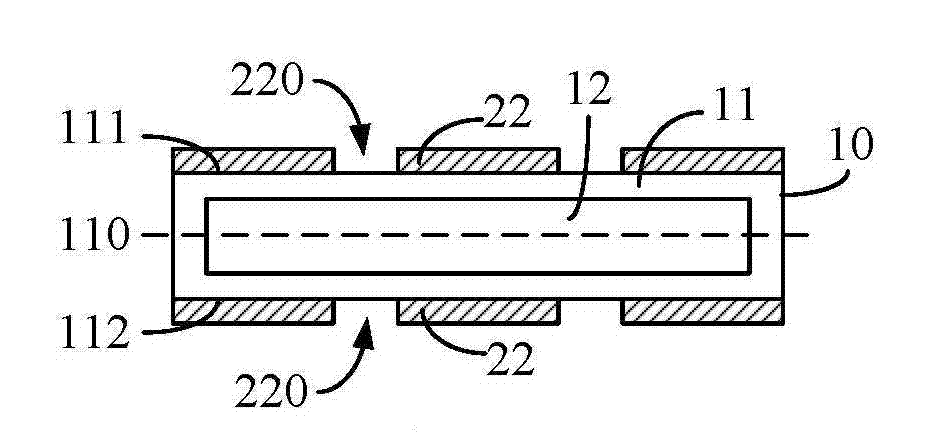

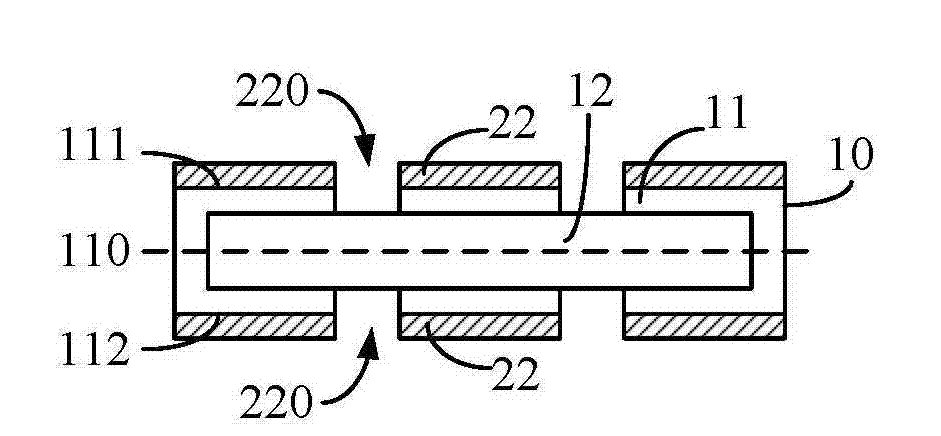

[0039] Firstly, the area to be cut 220 to be cut is planned on the strengthened glass 10, and then the cut adhesive film is directly attached to the surface of the strengthening layer 11 according to the distribution of the area to be cut 220 designed in advance, that is to say, using An adhesive film is attached to form the protection layer 22 including the area 220 to be cut.

Embodiment 2

[0041] completely coating the soluble material (or colloidal material) on the surface of the strengthening layer 12 of the strengthened glass 10, and then removing the soluble material according to the predetermined distribution of the region 220 to be cut, so that the distribution of the removed region of the soluble material Consistent with the distribution of the predetermined area 220 to be cut, the soluble material whose distribution has been designed is finally dried or baked to form the protective layer 22 including the area 220 to be cut.

Embodiment 3

[0043] A mask is covered on the surface of the strengthened layer 11 of the strengthened glass 10. This mask is designed according to the distribution of the predetermined region to be cut 220. The pattern of the mask is consistent with the distribution of the predetermined region to be cut 220, and then the The shield is placed together with the strengthened glass 10 in a chemical deposition machine, and a corrosion-resistant layer or an acid-resistant layer is plated on it, and then the shield is removed, that is to say, the patterned resist is formed by chemical deposition. In this way, the protective layer 22 including the area 220 to be cut is formed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com