Hard coating composition having antifouling performance

A technology of hard coating and composition, applied in the direction of anti-fouling/underwater coating, coating, etc., which can solve problems such as insufficient, difficult to wipe off, hard to notice fingerprints, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~4

[0213] [Examples 1 to 4, Comparative Example 1]

[0214] Preparation of antifouling agent

[0215] In a 10 ml glass sample bottle, 2.0 g of any of the following antifouling additives (B) and (C) components and 8.0 g of methyl isobutyl ketone (MIBK) were weighed, sealed with a stopper, and shaken for 30 minutes. After confirming that the antifouling additive is completely dissolved, filter it through a PTFE (polytetrafluoroethylene) membrane filter with a pore size of 0.45 μm, and prepare an antifouling agent containing 20% by mass of component (B) or component (C) as an antifouling imparting component. sex conferring agent.

[0216] (B) Antifouling additives for ingredients

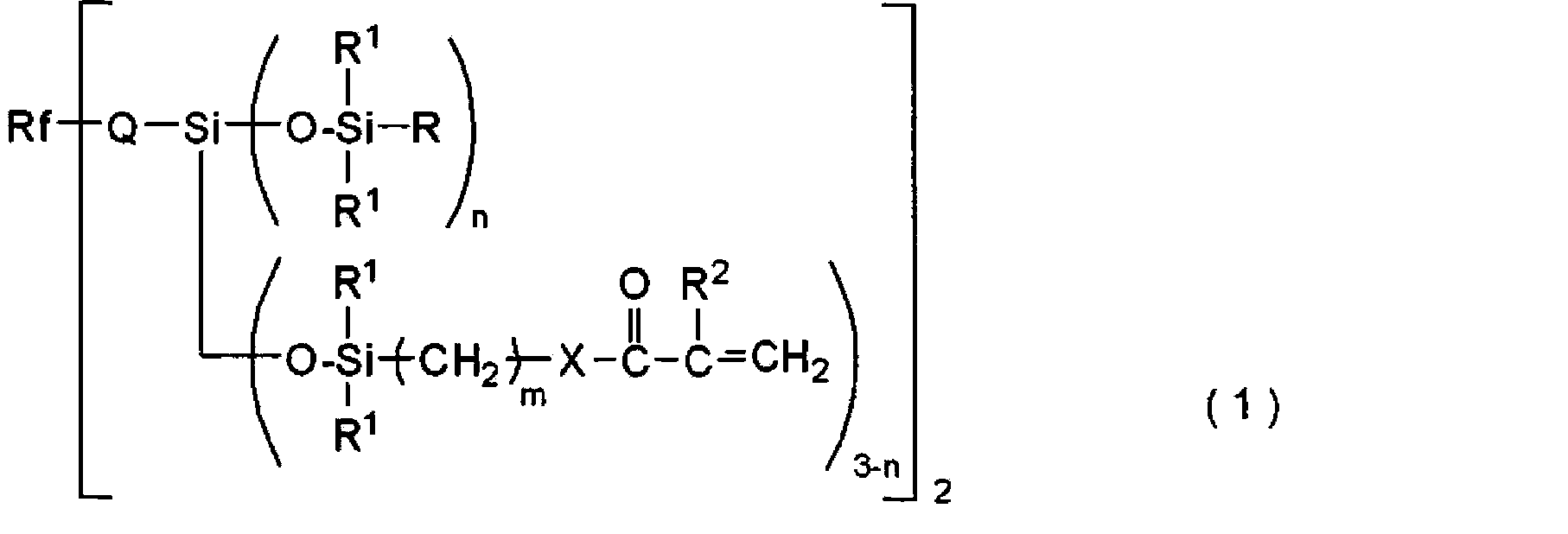

[0217] B-1

[0218] [chemical formula 29]

[0219]

[0220] B-2

[0221] [chemical formula 30]

[0222]

[0223] B-3

[0224] [chemical formula 31]

[0225]

[0226] (C) Antifouling additives of ingredients

[0227] C-1

[0228] [chemical formula 32]

[0229]

[0230] Rf': -CF ...

Embodiment 5、6、 comparative example 2~4

[0265] In the same manner as in Example 1 above, a hard coat composition was prepared according to the formulations in Table 3 below.

[0266] [table 3]

[0267]

[0268] The hard coat coating material was prepared in the same manner as in Example 1 above, and the physical properties were measured in the same manner. As a result, the results in Table 4 below were obtained.

[0269] [Table 4]

[0270]

[0271] Synthesis examples of components B-1 to B-3 are shown below.

Synthetic example 1

[0273] Modulation of B-1 Components

[0274] Fill the flask with reflux cooling tube and thermometer into the following formula (I)

[0275] [chemical formula 34]

[0276]

[0277] 43.1 g (0.050 mol) of fluorine-containing hydrosiloxane, 21.1 g of toluene, and 0.04 g of platinum / vinylsiloxane complex toluene solution (0.2 mg as platinum) are shown. After heating the internal temperature to 60°C, 44.9 g (0.20 mol) of 1-hexadecene was added dropwise using a dropping funnel with the dropping speed adjusted so that the internal temperature would not exceed 70°C. After heating at 60 to 70° C. for 1 hour, the dropping rate was adjusted so that the internal temperature would not become 70° C. or higher, and 17.2 g (0.20 mol) of 4-pentenol was added dropwise. After confirming that the absorption from the SiH group of the fluorine-containing hydrosiloxane (I) disappeared by IR spectrum measurement, hexafluoro-m-xylene and excess cyclotetrasiloxane were distilled off under reduce...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com