Polyamide material with surface modified with quaternary ammonium salt and salicylaldehyde functional groups and preparation method of polyamide material

A functional group and surface modification technology, applied in the field of functional polymer materials, can solve the problems of waste of monomer raw materials, reduction of permeability, micropore blockage of polyamide materials, etc., achieve uniform distribution, reduce drug resistance, and simple method easy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

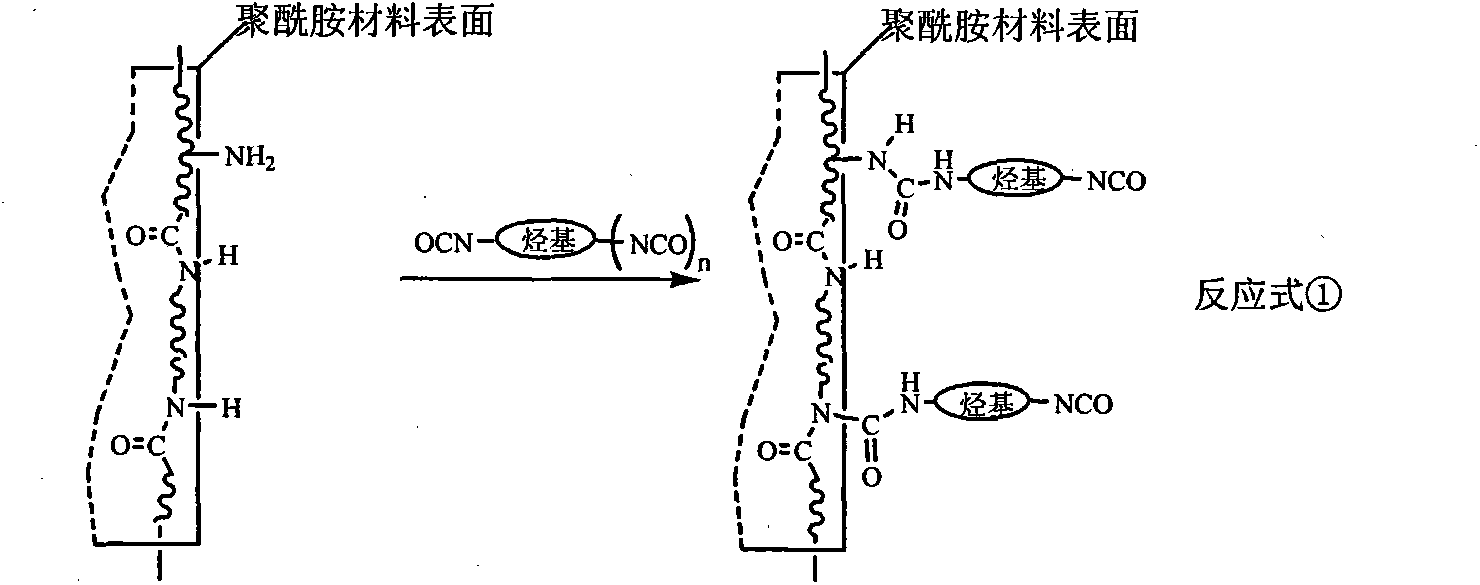

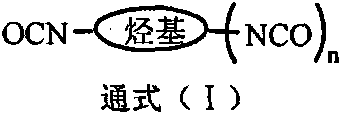

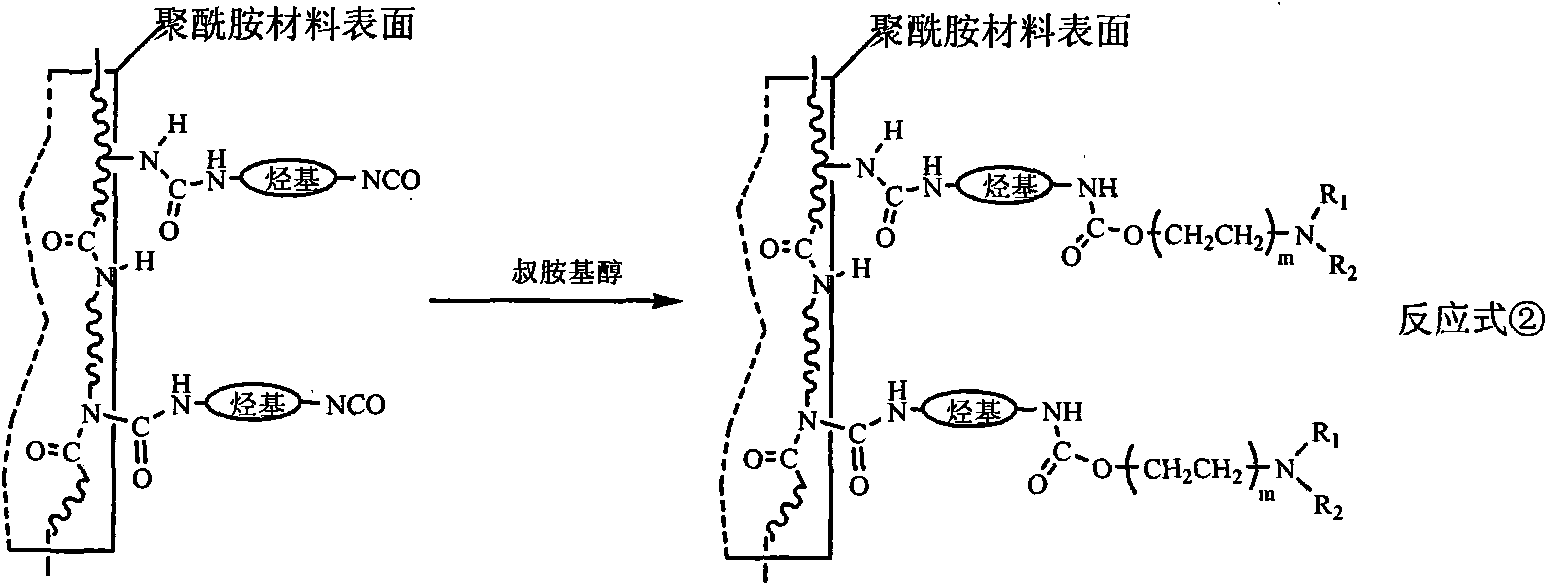

Method used

Image

Examples

Embodiment 1T

[0048] Example 1TDI-Et 2 Preparation of N-CMS-PA-66

[0049] Step 1, the preparation of TDI-PA-66

[0050] Take the purified and dried nylon-66 microfiltration membrane with a weight of 0.7751 grams produced by Shanghai Chuding Analytical Instrument Co., Ltd. and the model is 50mm*0.45μm. Immerse it in 1,4-dioxane solvent and activate it at room temperature for 24 hours. . Weigh 0.55 g of toluene diisocyanate and dissolve it in 2.5 ml of 1,4-dioxane solvent, add an appropriate amount of 4-dimethylaminopyridine to prepare a toluene diisocyanate solution. After taking out the activated nylon-66 microfiltration membrane and drying it by centrifugation, immerse the nylon-66 microfiltration membrane in toluene diisocyanate solution, control the temperature to 60-65°C and seal the reaction for 2 hours, then use 1,4- Dioxane solvent washes the nylon-66 microfiltration membrane after reaction, removes free toluene diisocyanate, and dries, that is, the nylon-66 microfiltration membr...

Embodiment 2D

[0055] Embodiment 2DMI-Et 2 Preparation of N-CMS-PA-66

[0056] According to the method and operating steps of Example 1, the toluene diisocyanate in Step 1 of Example 1 was replaced with diphenylmethane diisocyanate (abbreviated as DMI), and DMI-Et 2 N-CMS-PA-66.

Embodiment 3

[0057] Example 3TDI-Et 2 Preparation of NPEG-CMS-PA-66

[0058] According to the method and operation steps of Example 1, the N,N-diethylethanolamine in Step 2 of Example 1 was replaced with monodiethylamino polyethylene glycol (abbreviated as Et 2 NPEG), TDI-Et was obtained 2 NPEG-CMS-PA-66.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com