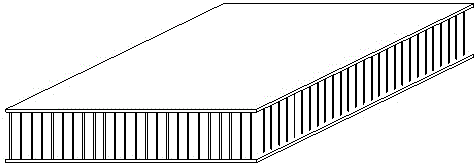

A composite thermal insulation exterior wall panel

A composite thermal insulation and exterior wall panel technology, applied in building components, buildings, building structures, etc., can solve problems such as hot air flow, unfavorable composite board installation, loss, etc., to improve thermal insulation performance, solve heat loss, and improve thermal insulation. effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

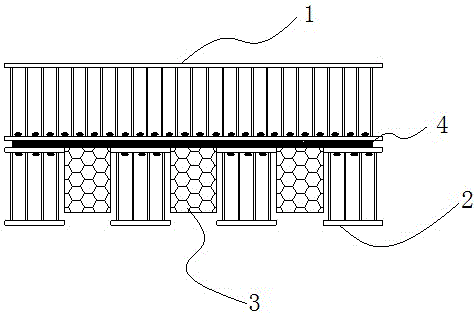

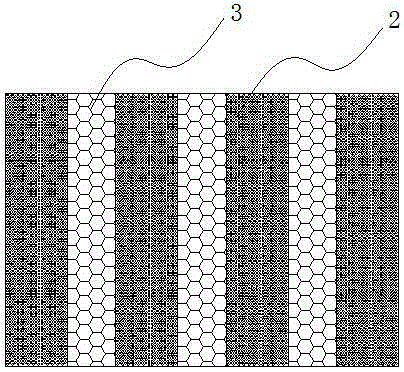

[0026] according to figure 2 As shown, the composite thermal insulation exterior wall panel in the present invention is mainly composed of a mother board 1, a sub-board 2 and a foam board 3 respectively pasted on one side panel of the mother board by resin. There are at least two sub-boards and foam boards, and in the embodiment, there are four sub-boards 2 and three foam boards 3 .

[0027] Among them, the main board 1 and the daughter board 2 are mainly cut and made of a three-dimensional hollow fabric composite rigid grid.

[0028] The three-dimensional hollow fabric composite rigid grid is mainly made of three-dimensional three-dimensional fabrics woven from fiber materials impregnated with resin and then cured (basalt fibers are preferred in this embodiment). The three-dimensional fabric is mainly composed of a surface layer woven from basalt fiber yarns, a basalt fiber connecting warp and a back layer woven from basalt fiber yarns. The three-dimensional fabric is wove...

Embodiment 2

[0033] Such as Figure 5As shown, on the basis of the technical solution described in Embodiment 1, the other side panel of the mother board 1 in the direction away from the daughter board 2 is densely covered with third through holes, and an inorganic phase change material insulation layer is bonded by resin 5. After the resin passes through the third through hole, it solidifies on the back of the other side panel of the motherboard 1 to form a coagulation with a diameter larger than that of the third through hole. These coagulations also act as "rivets" similar to the aforementioned "rivets" for anti-delamination role. Of course, it is also possible to directly spray polystyrene particle thermal insulation mortar on the other side panel of the motherboard 1. After the thermal insulation mortar passes through the third through hole, it solidifies on the back of the other side panel of the motherboard 1 to a diameter larger than that of the third through hole. Congealed block...

Embodiment 3

[0036] On the basis of the above embodiments, the motherboard 1 is further improved: the motherboard 1 is composed of two (or more) three-dimensional hollow fabric composite rigid grids that are sequentially laminated and bonded to form the motherboard 1 The three-dimensional hollow fabric composite rigid grid is also densely covered with through holes for resin to pass through on the panels bonded to each other. The two three-dimensional hollow fabric composite rigid grids are bonded by resin, and the resin is solidified on the back of the panel after the through hole under pressure to form a coagulated block with a diameter larger than the diameter of the through hole. These clots lock the two three-dimensional hollow fabric composite rigid grids like "rivets" one by one, which greatly strengthens the anti-delamination ability of the two three-dimensional hollow fabric composite rigid grids after bonding.

[0037] For the technical solutions described in the above embodiment...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com