Current temperature on-line fault indicator and method for judging fault

A fault indicator and temperature sensor technology, used in thermometers, thermometer parts, measuring current/voltage, etc., can solve the problems of magnets burning insulating shells, accidents, and insufficient response, and achieve long-distance or wireless transmission. , saving space and cost, quick and responsive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

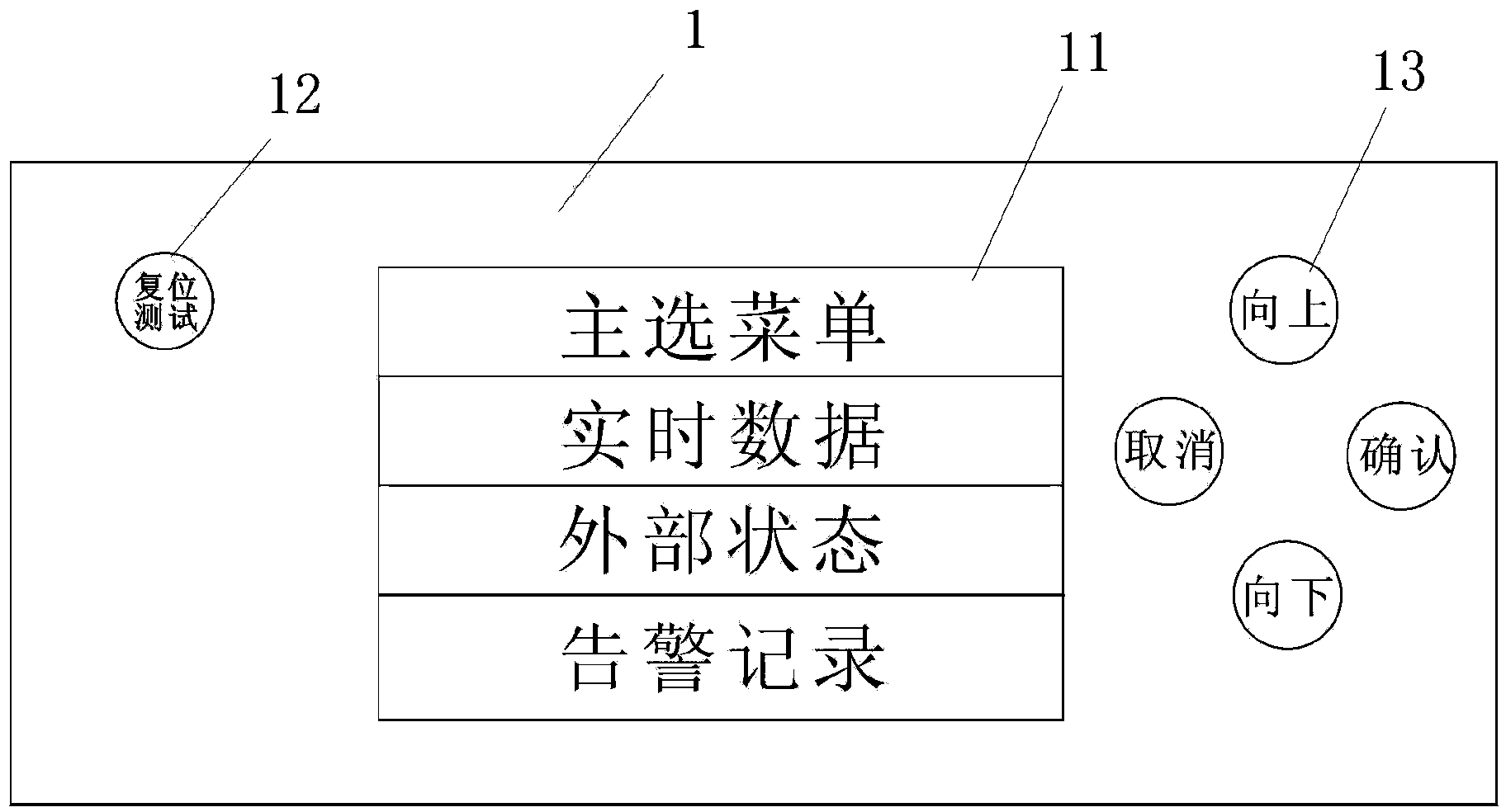

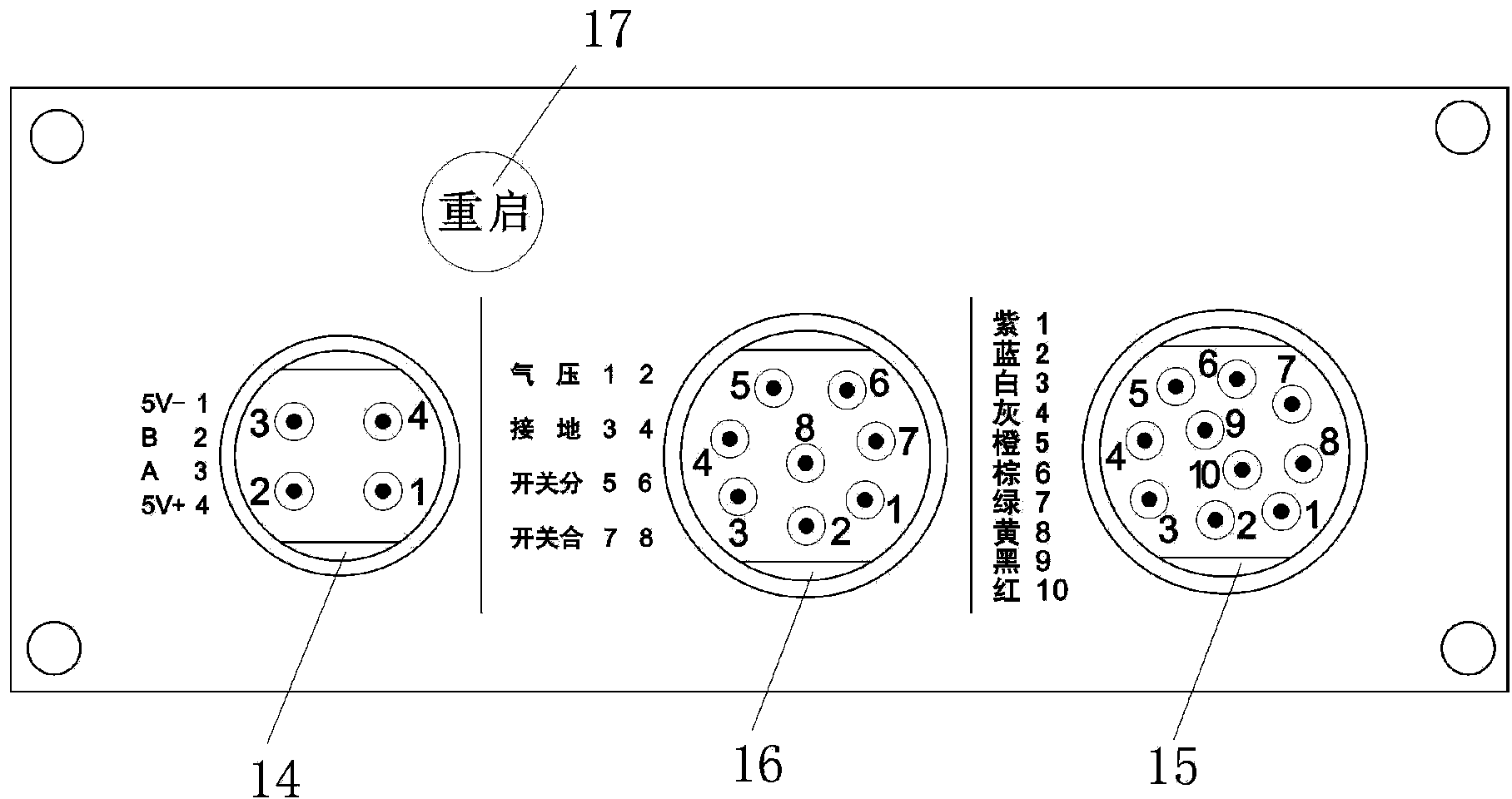

[0063] see figure 1 On the front panel of the host 1, there are a color LCD display window 11, a reset / test button 12 and a function button 13, and the signals of the phase line current and temperature sensors are transmitted to the host through cables and displayed on the color LCD display window 11. Current and temperature, the signal of the grounding current sensor is transmitted to the host through the cable and displays the current through the color LCD display window 11. The host computer includes a main chip connected with an analog-to-digital conversion module, a button control module, a voltage monitoring module, a reset circuit, a power supply circuit, a clock circuit, a liquid crystal display circuit, a signal transmission circuit and a communication circuit. The analog-to-digital conversion circuit of the main chip is used to convert the switch signal of the cable into a digital signal and send it.

[0064] The host has a function menu, which can simultaneously di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com