Double-L shaped current sharing stress-resistant IGBT (insulated gate bipolar transistor) module busbar terminal

A module busbar and stress-resistant technology, which is applied in the direction of electrical components, electric solid devices, circuits, etc., can solve problems that affect the reliability of IGBT modules, weaken the symmetry of the liner 1, and uneven current distribution, so as to reduce non-current Flow through the path area, good current sharing characteristics, and reduce the effect of the magnetic field penetration area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

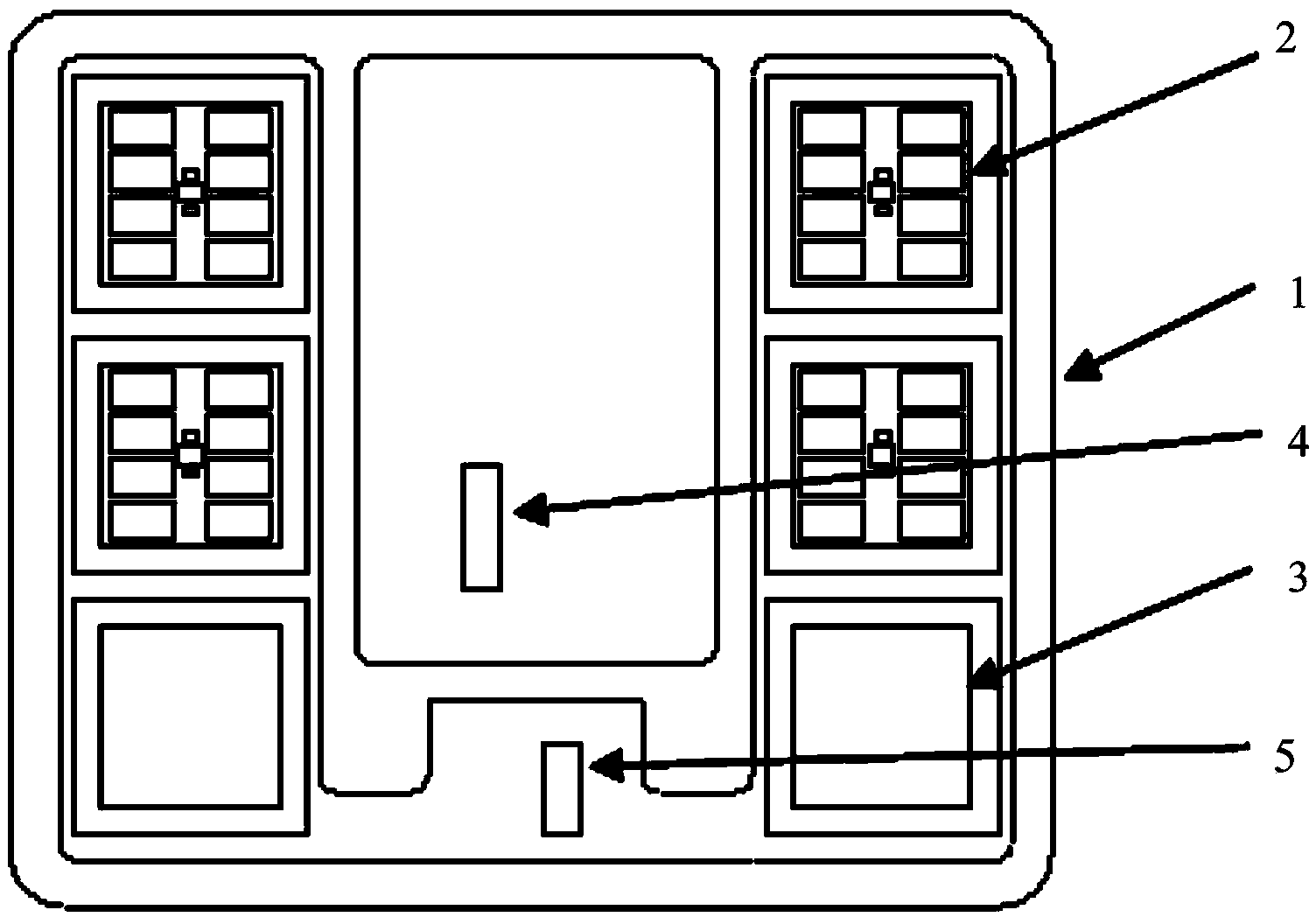

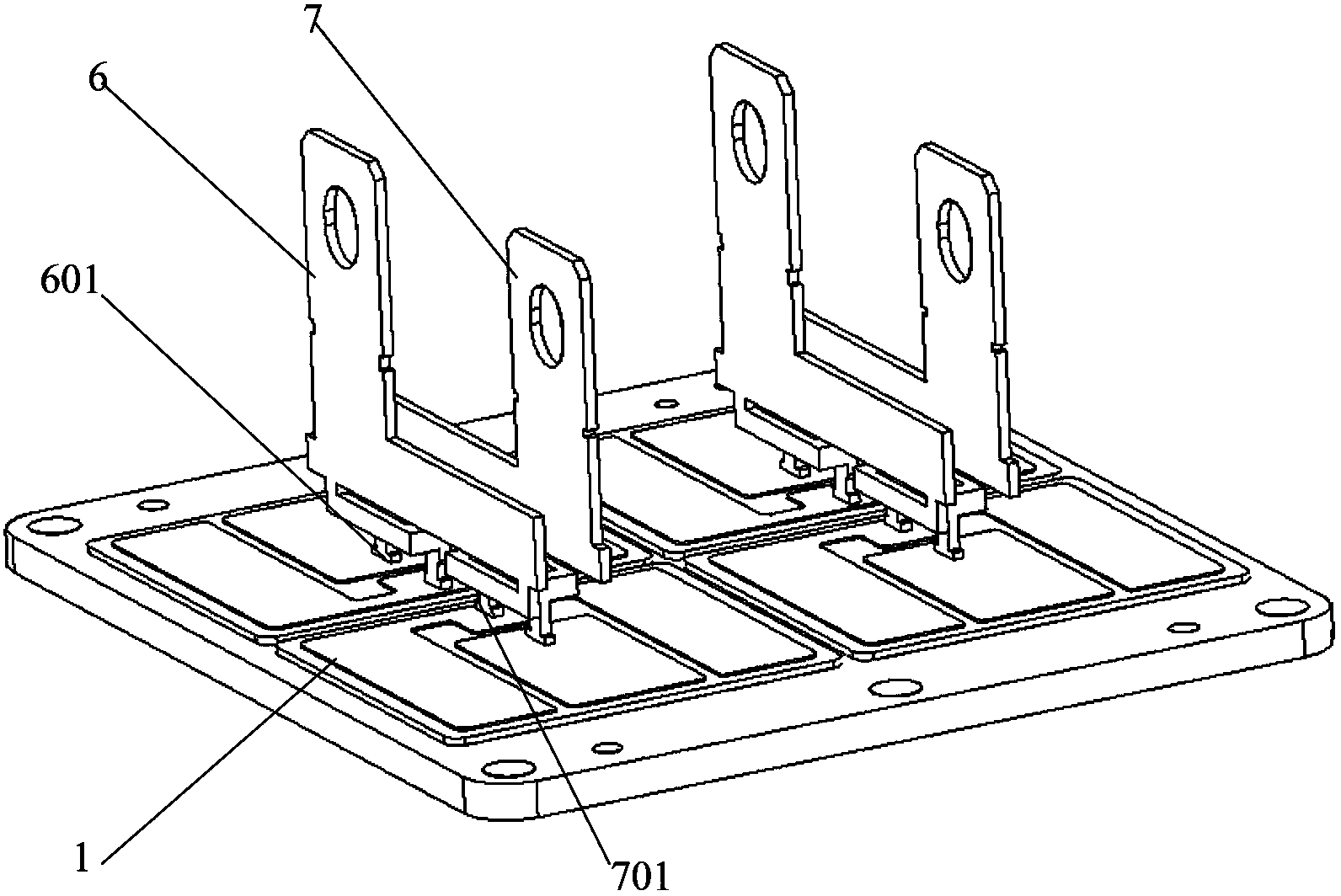

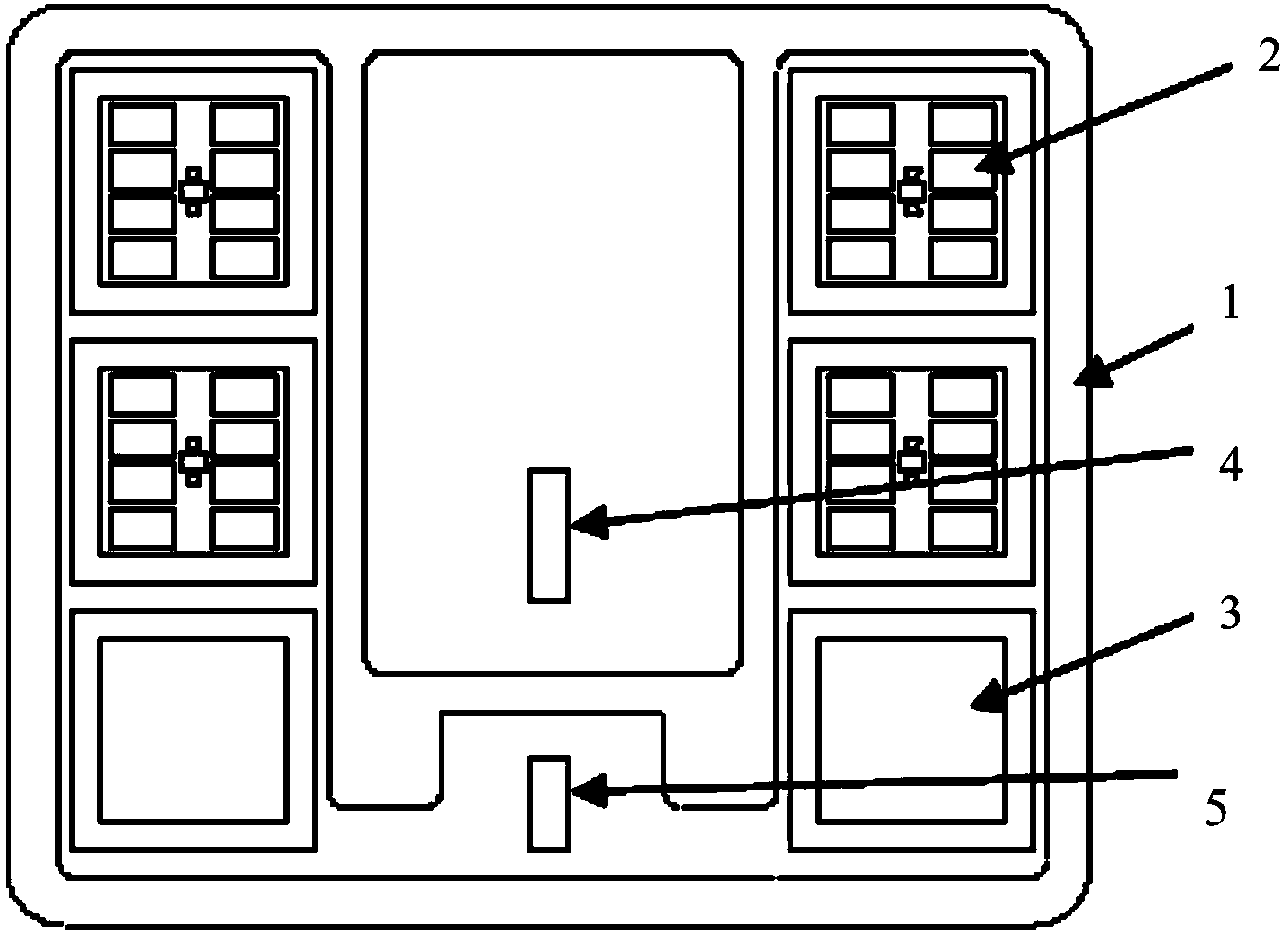

[0022] like figure 2 , image 3 , Figure 4 and Figure 5 As shown, the double L-shaped current-sharing and stress-resistant IGBT module busbar terminal of the present invention includes an emitter busbar 6 and a collector busbar 7, and two L-shaped first pins are arranged below the emitter busbar 6 601, two L-shaped second pins 701 are arranged below the collector busbar 7, and the two first pins 601 and the two second pins 701 are on the same straight line during welding.

[0023] In this embodiment, the distance between the two first pins 601 on the emitter busbar 6 is greater than the distance between the two second pins 701 on the collector busbar 7, and the two second pins 701 during welding 701 is located between the two first pins 601 .

[0024] In another embodiment, the distance between the two second pins 701 on the e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com