Photovoltaic device, manufacturing method thereof, and photovoltaic module

A photovoltaic device and light-receiving surface technology, applied in photovoltaic power generation, final product manufacturing, sustainable manufacturing/processing, etc., can solve problems such as increased compound speed, reduced photovoltaic power, and reduced quality of semiconductor crystals, achieving ease of constraints, high photoelectricity Improve conversion efficiency and achieve cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

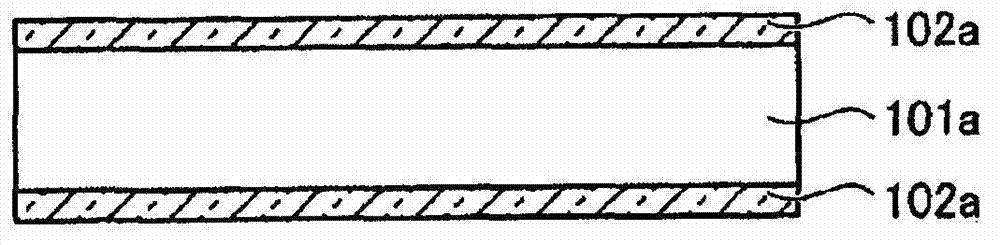

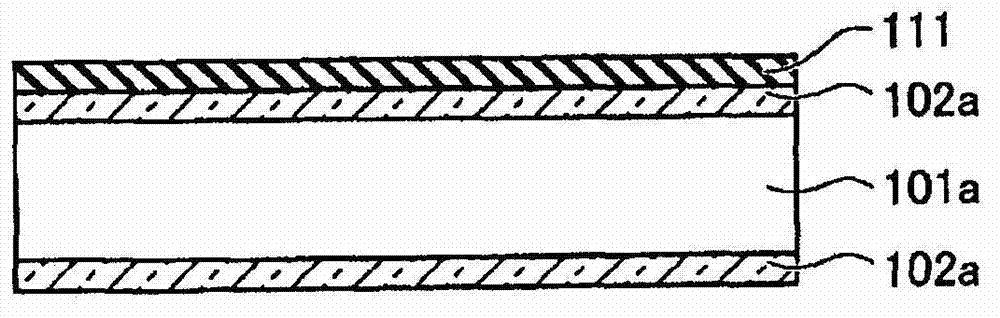

[0057] Below, refer to Figure 1-1 to Figure 1-10 as well as Figure 2-1 to Figure 2-10 , while following the manufacturing process, the embodiment of the present invention will be described. Figure 1-1 to Figure 1-10 It is a sectional view showing an example of a method of manufacturing a photovoltaic device according to an embodiment of the present invention. Figure 2-1 to Figure 2-10 It is a perspective view showing an example of a method of manufacturing a photovoltaic device according to an embodiment of the present invention. Figure 2-1 to Figure 2-10 The steps shown correspond to the Figure 1-1 to Figure 1-10 the steps shown.

[0058] First, as a semiconductor substrate, for example, a p-type polysilicon substrate (hereinafter referred to as a p-type silicon substrate 101 a ) that is most widely used as a commercial solar cell is prepared ( Picture 1-1 , diagram 2-1 ).

[0059] The p-type silicon substrate 101a is produced by cutting and slicing a single-crys...

example 1

[0106] In the case of grid electrode spacing = 1 mm, process limit for patterning of high-concentration n-type diffusion layer = 100 μm (0.1 mm):

[0107] (0.1mm×0.1mm) / (1mm×1mm)=0.01(=1%)

[0108] (lower limit value example 2)

[0109] In the case of grid electrode spacing = 2 mm, process limit for patterning of high-concentration n-type diffusion layer = 100 μm (0.1 mm):

[0110] (0.1mm×0.1mm) / (2mm×2mm)=0.0025 (=0.25%)

[0111] In addition, in addition to the discontinuous shape, as the shape of the high-concentration n-type diffusion layer, a "wavy shape" that is continuous in the direction perpendicular to the longitudinal direction of the grid electrode in the light-receiving surface of the photovoltaic device and has a variable width is also proposed. "shape( Figure 9 ). Figure 9 It is a plan view schematically showing an example of the pattern of the high-concentration n-type diffusion layer 102a in this embodiment. exist Figure 9 middle, Figure 9 (a) shows a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com