An Improved Diffusion Furnace Exhaust Gas Emission Device

A technology of tail gas emission and diffusion furnace, applied in the directions of diffusion/doping, crystal growth, post-processing, etc., can solve problems such as being unfavorable to ensure the stability of airflow in the quartz tube, achieve constant pressure, increase stability and repeatability, maintain The effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

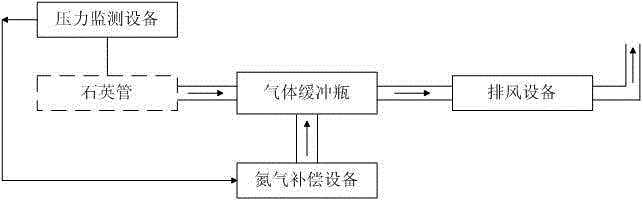

Problems solved by technology

Method used

Image

Examples

Embodiment 1

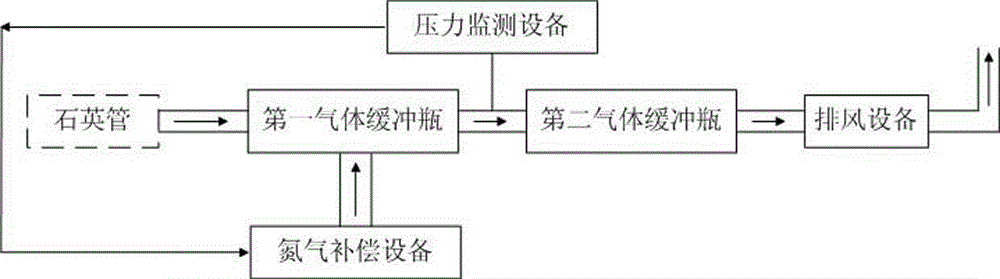

[0023] Depend on image 3 It can be seen that the improved diffusion furnace tail gas treatment device includes the first gas buffer bottle, the second gas buffer bottle, exhaust equipment, pressure monitoring equipment and nitrogen compensation equipment, and the one-way connection between the pressure monitoring equipment and the nitrogen compensation equipment One end of the first gas buffer bottle is connected to the quartz tube of the diffusion furnace, the other end of the first gas buffer bottle is connected to the exhaust equipment after passing through the second gas buffer bottle, and the nitrogen compensation device is located at On the first gas buffer bottle, the pressure monitoring device is arranged on the connecting pipe between the first gas buffer bottle and the second gas buffer bottle.

Embodiment 2

[0025] Depend on Figure 4 As can be seen, the difference from Embodiment 1 is that the pressure monitoring device is arranged on the second gas buffer bottle.

Embodiment 3

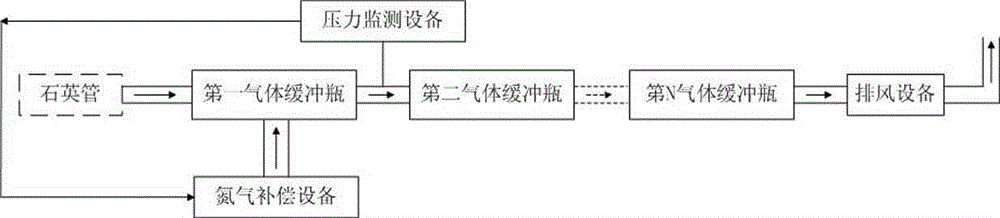

[0027] Depend on Figure 5 As can be seen, the difference from Embodiment 1 is that the first gas buffer bottle is connected to the exhaust device through the sequentially connected second gas buffer bottle and the third gas buffer bottle. The nitrogen compensation device is arranged on the first gas buffer bottle, and the pressure monitoring equipment is arranged on the connecting pipe between the first gas buffer bottle and the second gas buffer bottle or on the second gas buffer bottle.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com