Electroosmosis united air pressure separation device and technology

A technology of air pressure and electroosmosis, which is applied in infrastructure engineering, soil protection, construction, etc., can solve the problems of restricting the development of electroosmosis, poor economic benefits, and poor treatment effect of deep soil, so as to facilitate drainage and consolidation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

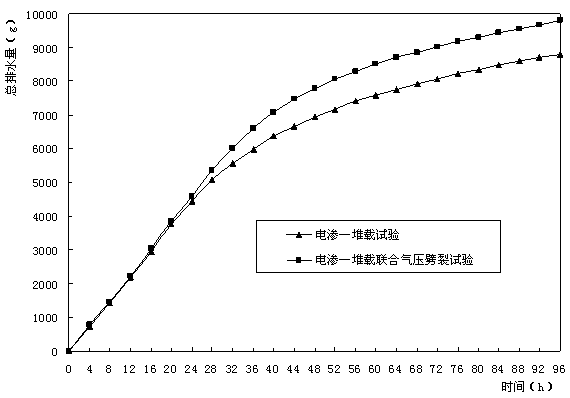

[0036] Experimental protocol

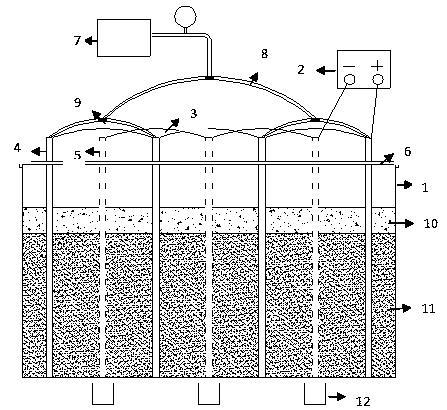

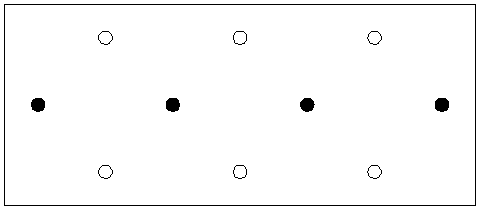

[0037] The size of the model box used is 700×300×400mm (outer edge). The electrode material is aluminum tube. During the test, the anode is also used as a jet tube. The anode is 450mm long, 16mm in outer diameter, and 10mm in inner diameter. Small holes with a diameter of 2mm are drilled at the bottom 50mm and 150mm. The cathode is 450mm long, with an outer diameter of 24mm and an inner diameter of 18mm, and small holes with a diameter of 4mm are evenly distributed in the bottom 300mm. The arrangement of the electrodes is in parallel dislocation arrangement, the distance between the electrodes of the same sex is 200 mm, and the distance between the electrodes of the opposite sex is 141 mm.

[0038] Set up a group of control experiments, that is, compare the two situations of electroosmosis-surcharge combined splitting and electroosmosis-surcharge. Electroosmosis-surcharge combined splitting test steps are as follows:

[0039] 1) Screw the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com