Preparation method of silicon oxynitride thin film

A technology of silicon oxynitride and manufacturing method, which is applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve the problems of strong reading and writing performance and unstable product performance, achieve stable reading and writing performance, and reduce reading and writing performance. , the effect of uniform oxygen content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

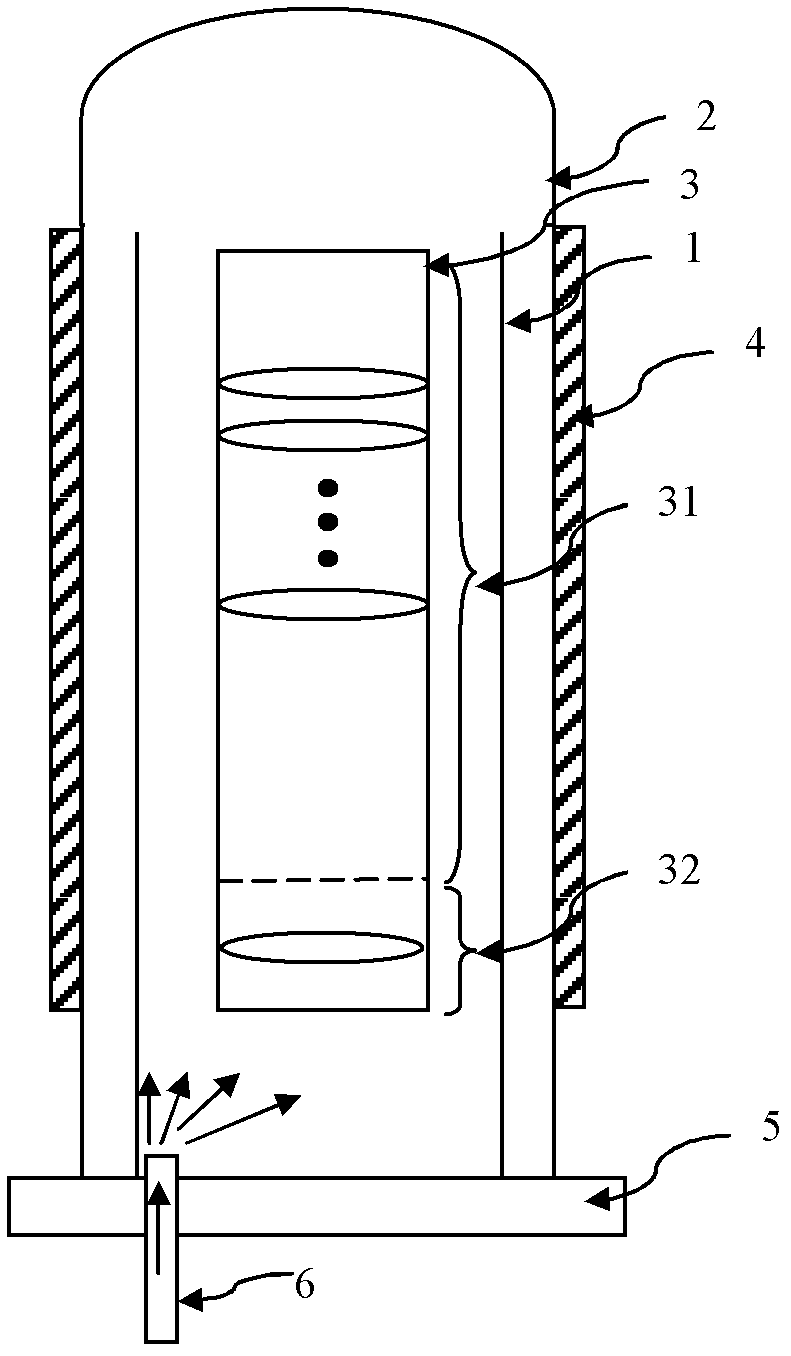

[0022] The manufacturing method of embodiment of the present invention-silicon oxynitride thin film adopts such as figure 1 The shown vertical LP CVD furnace tube grows a silicon oxynitride film, and the silicon wafer product is placed in the product operation area 31 of the vertical LP CVD furnace tube, and in the accompanying sheet placement area of the vertical LP CVD furnace tube 32 Place a quartz sheet, the diameter of the quartz sheet is the same as that of the silicon sheet product and both are 8 inches, and the thickness of the quartz sheet is more than 3 mm.

[0023] When the silicon oxynitride film is grown, the process gases used include: dichlorosilane (DCS), nitrous oxide and ammonia gas, which are silicon source, oxygen source and nitrogen source for forming the silicon oxynitride film respectively. Various process gases are equipped with different inlet pipes 6 respectively, and various process gases enter the bottom of the reaction chamber through their respe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com