Preparation method of catalyst protective agent filler

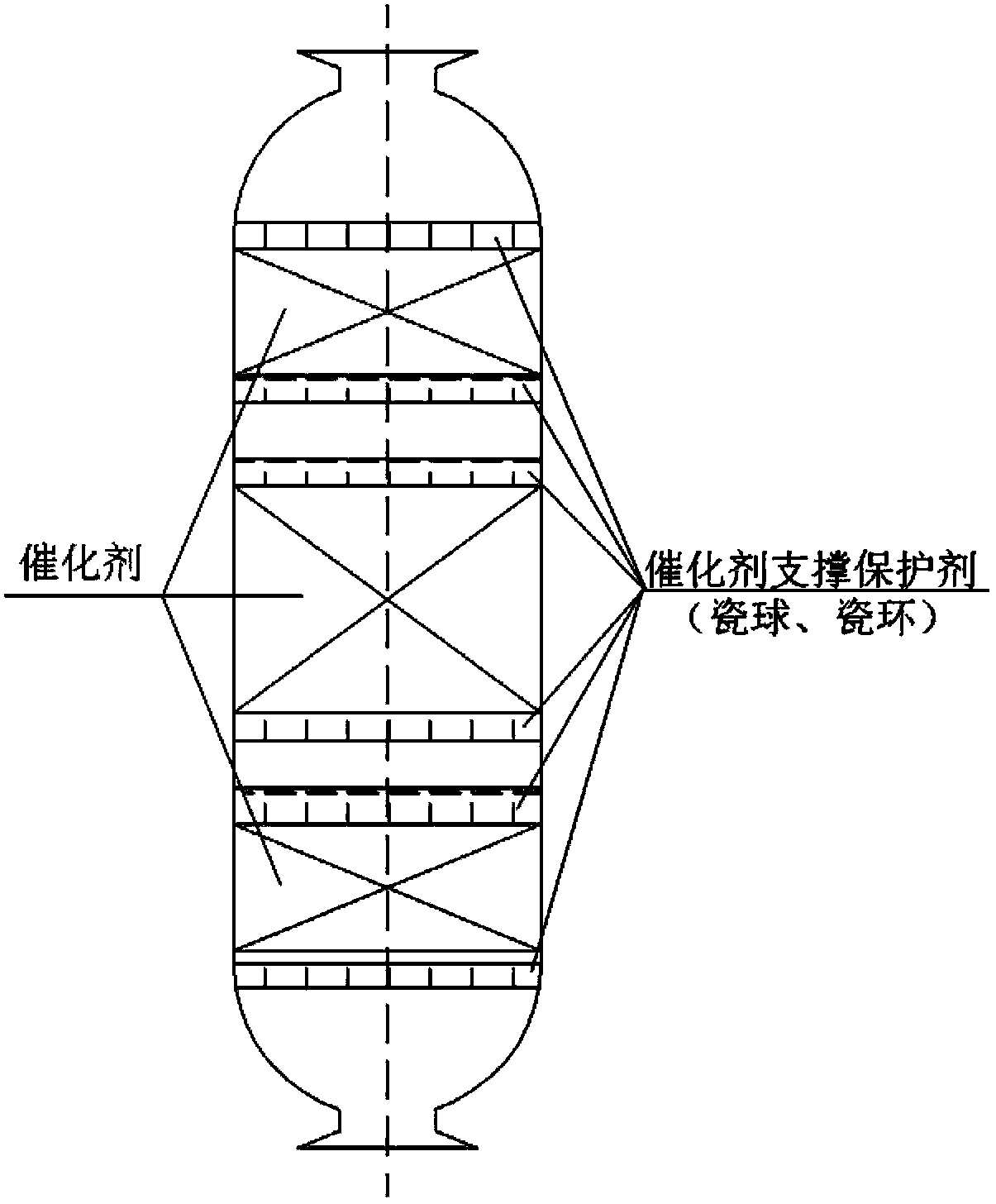

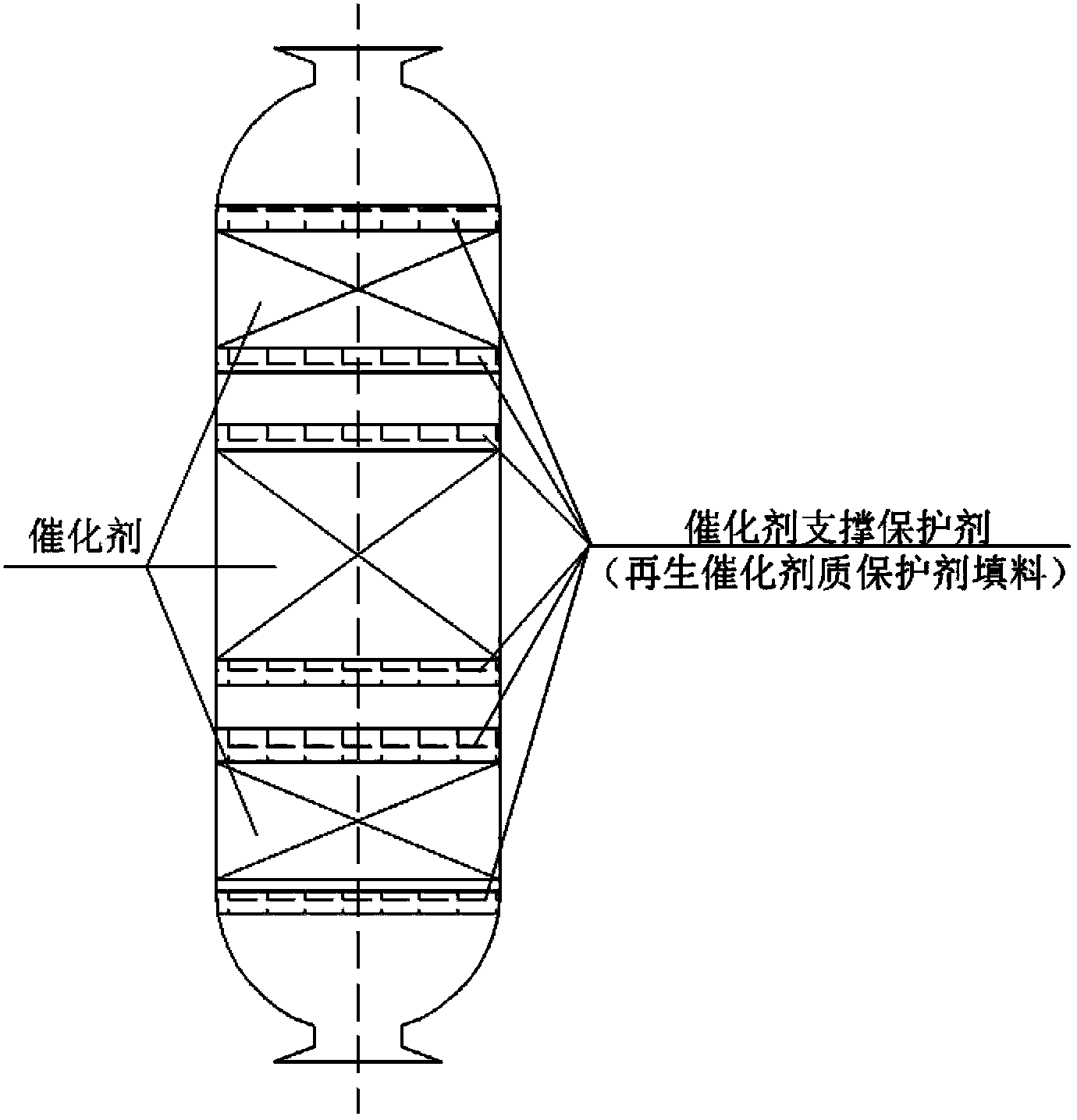

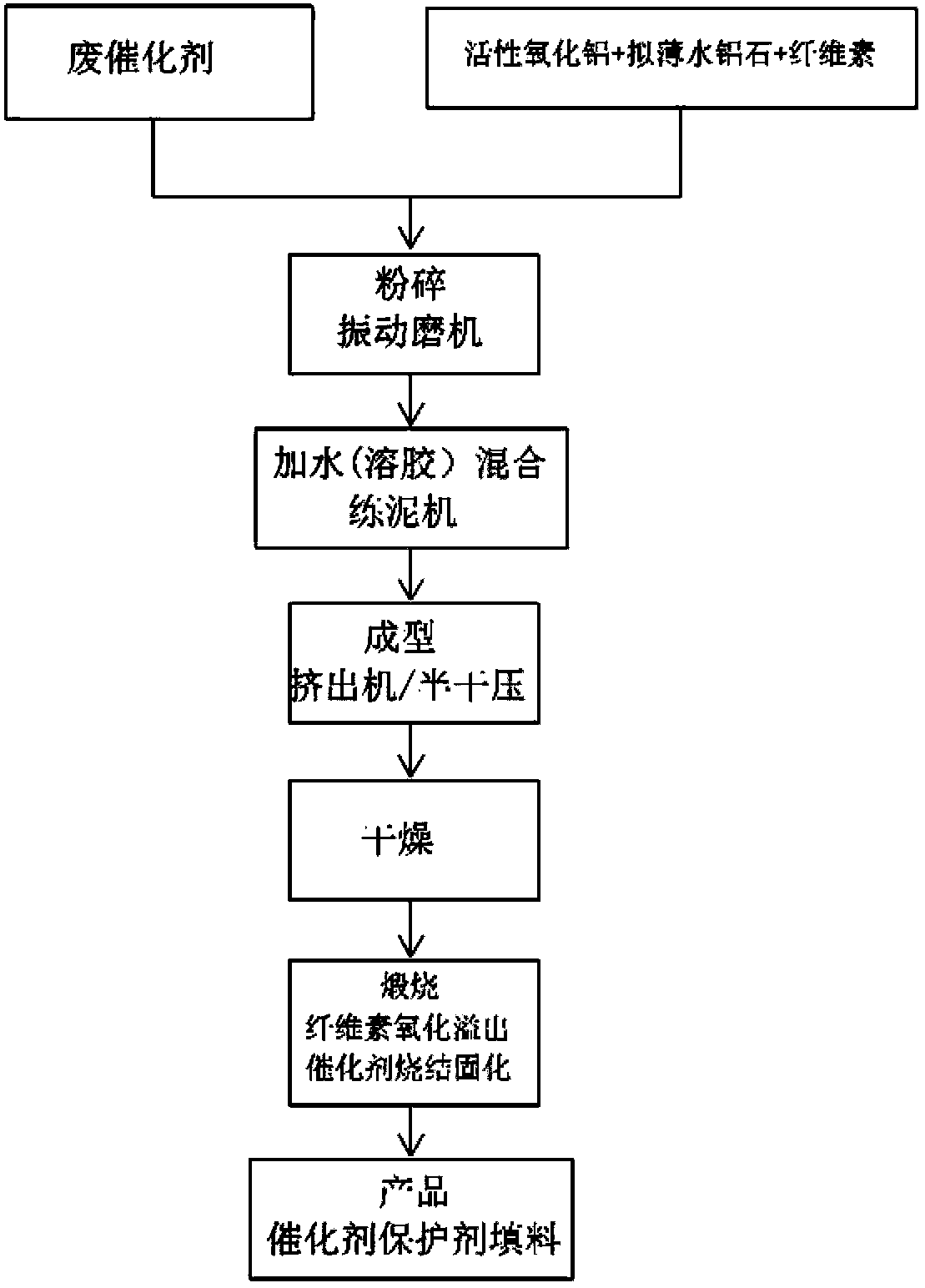

A technology of protecting agent and catalyst is applied in the field of preparation of catalyst protecting agent filler, which can solve the problems of polluting the environment and high energy consumption, and achieve the effects of improving efficiency, saving resources and high catalytic activity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Use the method shown above: by weight, active alumina is added 15%, pseudo-boehmite is added 15%, waste catalyst containing molybdenum, nickel, cobalt components 70%, cellulose 1%, water 25%, program The sintering process is: 20°C-160°C for 2 hours, 160°C-380°C for 2 hours, and 380°C-580°C for 4 hours to obtain the catalyst protection agent packing of Example 1: Ф5mm Raschig rings (such as Figure 5 ), the chemical composition is by weight:

[0041] Al 2 o 3 : 87%MoO 3 : 8.5%NiO: 1.5%CoO: 3% Physical properties: specific surface area 133m 2 / g, bulk density 720Kg / m 3 ,compressive strength≥33N / grain

Embodiment 2

[0043] Using the method shown above: by weight, activated alumina 15%, pseudoboehmite 15%, spent catalyst containing molybdenum and cobalt components 70%, cellulose 1%, water 25%, programmed sintering process For: 20 ° C ~ 160 ° C for 2 hours, 160 ° C ~ 380 ° C for 1 hour, 380 ° C ~ 580 ° C for 4 hours, to obtain Example 2 Catalyst protection agent filler: Ф6mm Raschig rings, the chemical composition is by weight:

[0044] Al 2 o 3 : 90% MoO 3 : 8%CoO: 2%

[0045] The physical properties are: the specific surface area is 130m 2 / g, bulk density 700Kg / m 3 ,compressive strength≥33N / grain

Embodiment 3

[0047] Use the method shown above: by weight, add 25% of activated alumina, 60% of spent catalyst containing nickel and cobalt components, 15% of aluminum sol, 1.5% of cellulose, 20% of water, and the programmed sintering process is: 20°C ~160°C for 1 hour, 160°C~380°C for 2 hours, 380°C~580°C for 4 hours to obtain Example 3 Catalyst protection agent packing: Ф8mm Raschig rings, chemical composition by weight:

[0048] Al 2 o 3 : 90%NiO: 2.5%MoO 3 : 7.5%

[0049] The physical properties are: the specific surface area is 139m 2 / g, bulk density 650Kg / m 3 ,compressive strength≥66N / grain

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com