Polybutylene succinate resin composition and its preparation method

A technology of polybutylene succinate and resin composition, which is applied in the field of polymer material modification, can solve the undiscovered problems of PBS impact resistance and tensile strength, and achieve the improvement of mechanical properties and heat resistance, High impact performance, good fluidity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

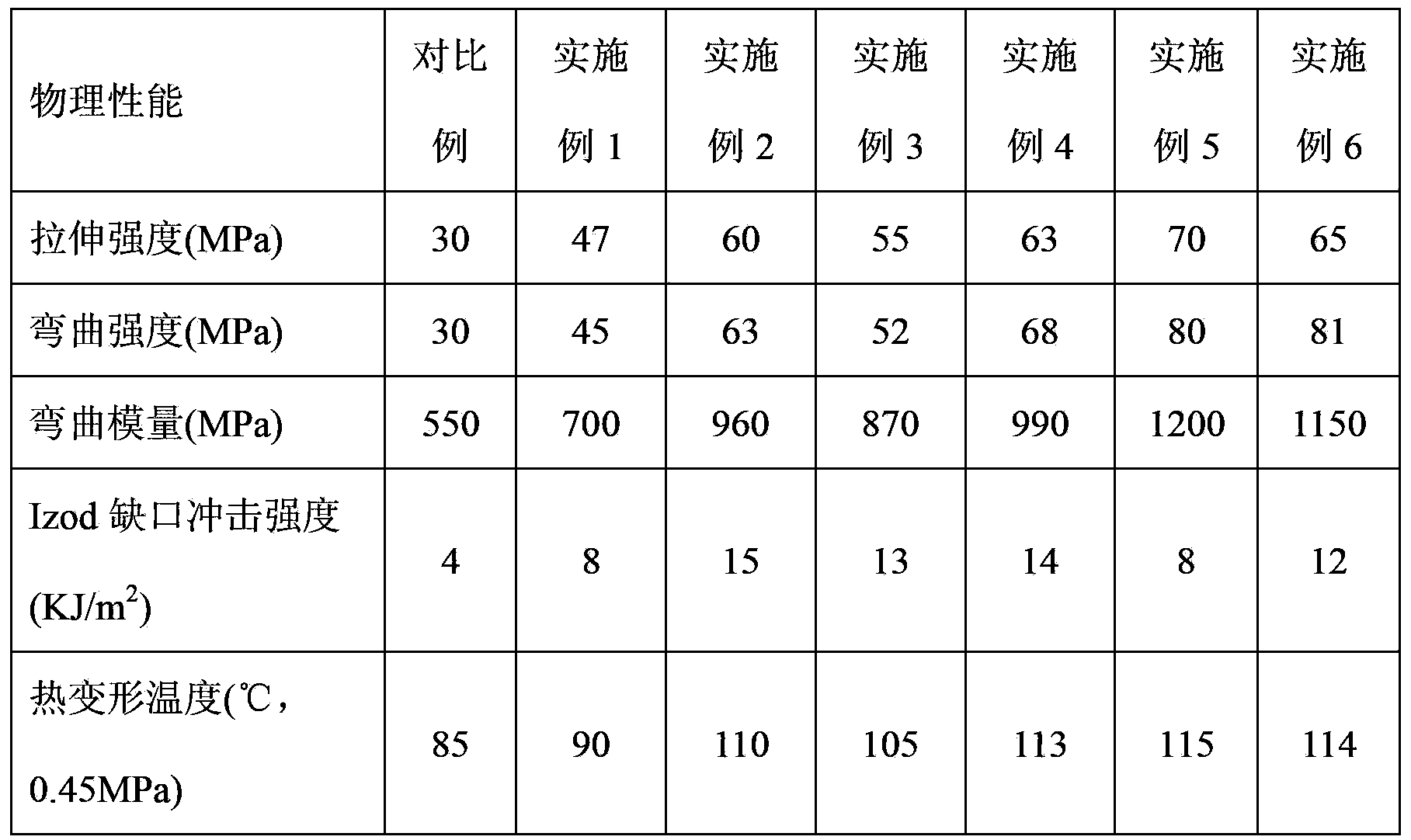

Examples

Embodiment 1

[0034]50wt% polybutylene succinate (melt index: 9g / 10min, test condition: 190°C, 2.16kg), 20wt% EPDM rubber (38% propylene content), 20wt% Malay Anhydride grafted polypropylene (maleic anhydride graft rate 3%), 1wt% aminosilane coupling agent (KH550) and 0.4wt% antioxidant β-(3,5-di-tert-butyl-4-hydroxy Phenyl)stearyl propionate (IRGANOX1076) and 0.6wt% tris(2,4-di-tert-butylphenyl)phosphite (IRGAFOS168) were stirred in a high-speed mixer for 5 minutes, and after mixing evenly, put After the twin-screw extruder, add 8wt% alkali-free glass fiber to the fiber inlet, and extrude to pelletize. The length-to-diameter ratio of the twin-screw extrusion equipment is 35, the controlled feeding speed is 8rpm, the screw speed is 200rpm, and the temperature of each partition of the screw barrel is 100°C for the first partition, 140°C for the second partition, 140°C for the third partition, and 140°C for the fourth partition. Zone 145°C, fifth zone 145°C, sixth zone 145°C, seventh zone 14...

Embodiment 2

[0036] 58.3wt% polybutylene succinate resin (melt index is 9g / 10min, test condition is 190°C, 2.16kg), 18wt% EPDM rubber (propylene content 32%), 5wt% Maleic anhydride grafted EPDM (maleic anhydride graft rate 2%), 0.5wt% epoxy silane coupling agent (KH570) and 0.2wt% antioxidant tris(2,4-di-tert-butyl phenyl) ester (IRGAFOS168) was stirred in a high-speed mixer for 4 minutes, after mixing evenly, after being put into a twin-screw extruder, 18wt% alkali-free glass fiber was added to the fiber inlet, and extruded to granulate. The aspect ratio of the twin-screw extrusion equipment is 32, the feeding speed is controlled at 8rpm, the screw speed is 300rpm, and the temperature of each zone of the screw barrel is 100°C for the first zone, 140°C for the second zone, 140°C for the third zone, and 140°C for the fourth zone. Zone 145°C, fifth zone 145°C, sixth zone 145°C, seventh zone 140°C, eighth zone 140°C, ninth zone 130°C, die head temperature 130°C, strands were watered and pelle...

Embodiment 3

[0038] 54wt% polybutylene succinate resin (melt index is 9g / 10min, test condition is 190 ℃, 2.16kg), 20wt% SBS, 10wt% maleic anhydride grafted SBS (maleic anhydride grafted Branch rate 3.2%), 0.5wt% epoxy silane coupling agent (KH570) and 0.5wt% antioxidant β-(3,5-di-tert-butyl-4-hydroxyphenyl) octadecanoic acid Alcohol ester (IRGANOX1076) was stirred in a high-speed mixer for 3 minutes. After mixing evenly, it was put into a twin-screw extruder, and 15wt% alkali-free glass fiber was added to the fiber inlet, and extruded to granulate. The length-to-diameter ratio of the twin-screw extrusion equipment is 40, the feeding speed is controlled at 8rpm, the screw speed is 280rpm, and the temperature of each partition of the screw barrel is 100°C for the first partition, 140°C for the second partition, 140°C for the third partition, and 140°C for the fourth partition. Zone 145°C, fifth zone 145°C, sixth zone 145°C, seventh zone 140°C, eighth zone 140°C, ninth zone 130°C, die head te...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melt index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com