Mixed strain fermented beer beverage and its preparation method

A technology for mixing bacterial species and bacterial liquid, which is applied in beer fermentation methods, biochemical equipment and methods, and beer brewing, etc., can solve problems such as single taste and limited health care functions, and achieve the functions of improving immunity and promoting digestion and absorption. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] 1) Before the start of fermentation, activate and expand the beer yeast, Gluconacetobacter, and Lactobacillus casei in advance, and the amplification factor is 10. Taking 5 liters of fermented liquid as an example, the expansion step is 10mL-100mL-500mL, the medium used is 13°P wort, the expansion cultivation temperature is 25°C, and the cultivation time is 3 days.

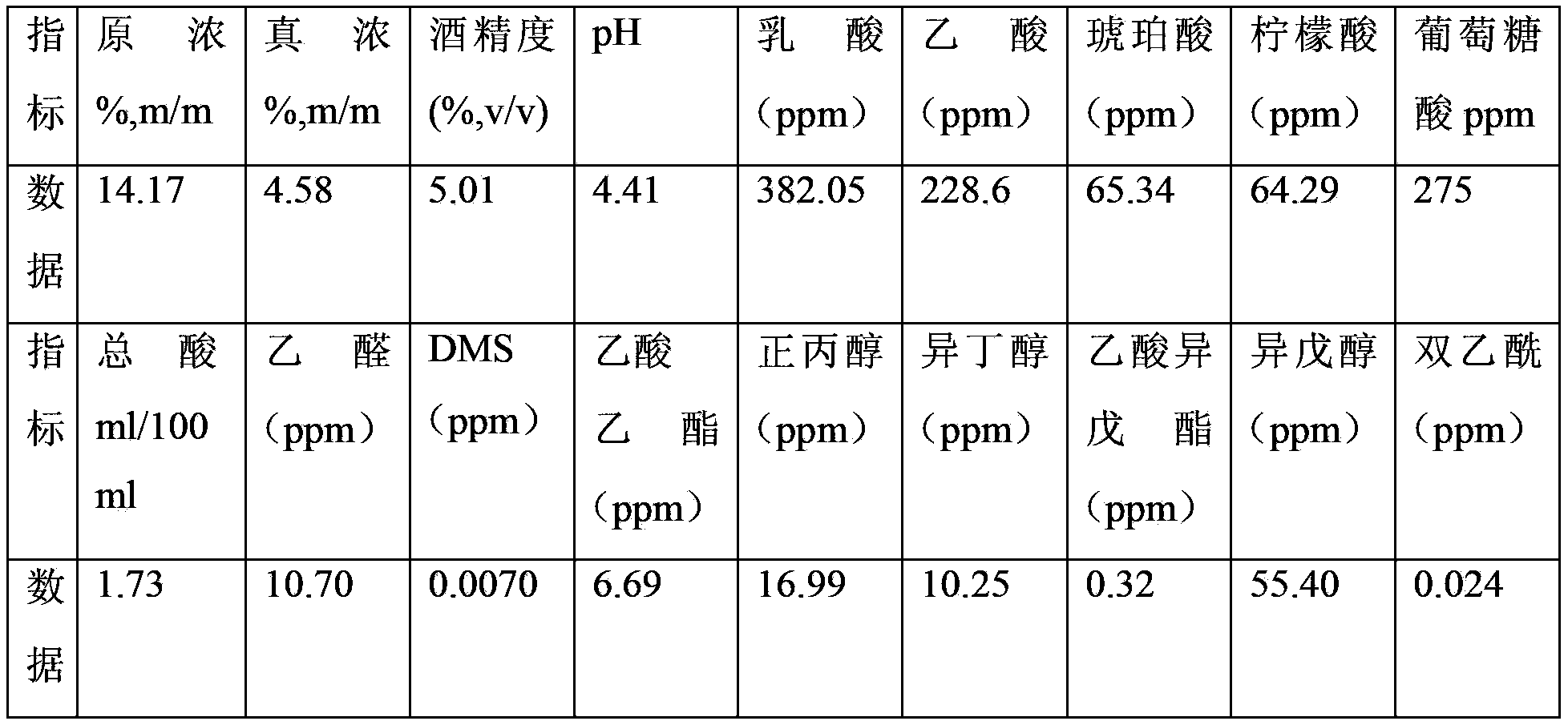

[0033] 2) Before the start of fermentation, mix the expansion medium of the three kinds of bacteria at a ratio of 1:1:1, take the mixed bacterial solution, and add it to the wort in an amount accounting for 10% of the wort used for fermentation. Keep at 11°C for cultivation and fermentation until the sugar content drops to 6°P, heat up to 13°C, then seal the tank, raise the pressure to 0.12-0.15mPa, keep it until the diacetyl drops below 0.12ppm, then cool down to 0°C and store until wine storage Mature, get rid of the sludge at the bottom of the tank. After the fermentation, the fermented liquid retains t...

Embodiment 2

[0036] 1) Before the start of fermentation, activate and expand the brewer's yeast, Gluconacetobacter, and Lactobacillus casei in advance, and the amplification factor is 10. Taking 5 liters of fermented liquid as an example, the expansion step is 10mL-100mL-500mL, the medium used is 13°P wort, the expansion cultivation temperature is 25°C, and the cultivation time is 3 days.

[0037] 2) Before the start of fermentation, mix the expansion medium of the above three different bacterial species at a ratio of 1:1:1, take the mixed bacterial solution, and add it to the wort in an amount accounting for 10% of the wort used for fermentation. Keep at 13°C for culture and fermentation until the sugar content drops to 6°P, then seal the tank, raise the temperature to 15°C, raise the pressure to 0.12-0.15mPa, keep until the diacetyl drops below 0.12ppm, then cool down to 0°C and store until wine storage Mature, get rid of the sludge at the bottom of the tank. After the fermentation, the...

Embodiment 3

[0040] 1) Before the start of fermentation, activate and expand the brewer's yeast, Gluconacetobacter, and Lactobacillus casei in advance, and the amplification factor is 10. Taking 5 liters of fermented liquid as an example, the expansion step is 10mL-100mL-500mL, the medium used is 13°P wort, the expansion cultivation temperature is 25°C, and the cultivation time is 3 days.

[0041] 2) Before the start of fermentation, mix the expansion medium of the three kinds of bacteria at a ratio of 1:1:1, take the mixed bacterial solution, and add it to the wort in an amount accounting for 10% of the wort used for fermentation. Keep at 15°C for culture and fermentation until the sugar content drops to 6°P, then seal the tank, raise the temperature to 15°C, increase the pressure to 0.12-0.15mPa, keep until the diacetyl drops below 0.12ppm, then cool down to 0°C and store until wine storage Mature, get rid of the sludge at the bottom of the tank. After the fermentation, the fermented li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com