Metal aluminum salt cover film

A metal aluminum salt, covering film technology, applied in metal material coating process, superimposed layer plating, coating and other directions, can solve the problems of high processing cost, difficult to paint or color, time-consuming and labor-intensive processing, and achieve electrical conductivity. The effect of excellent performance, water saving and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

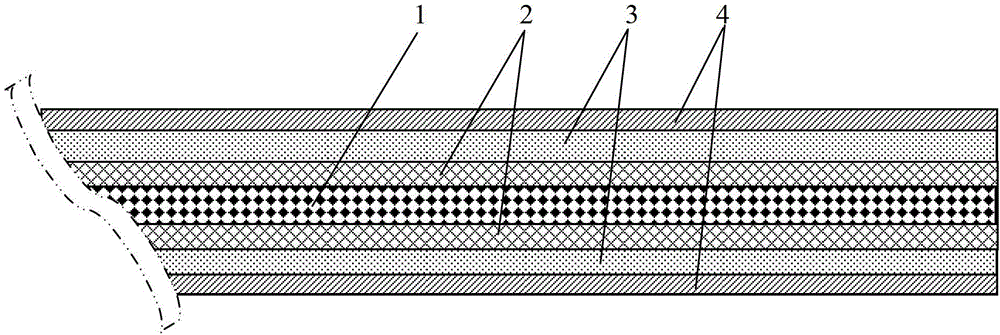

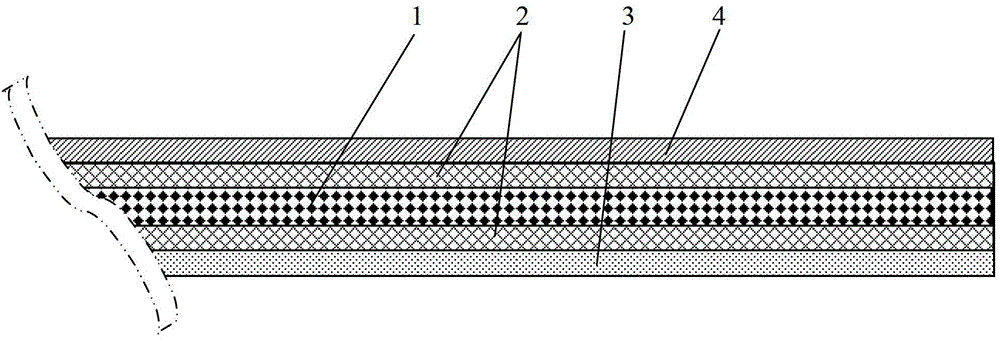

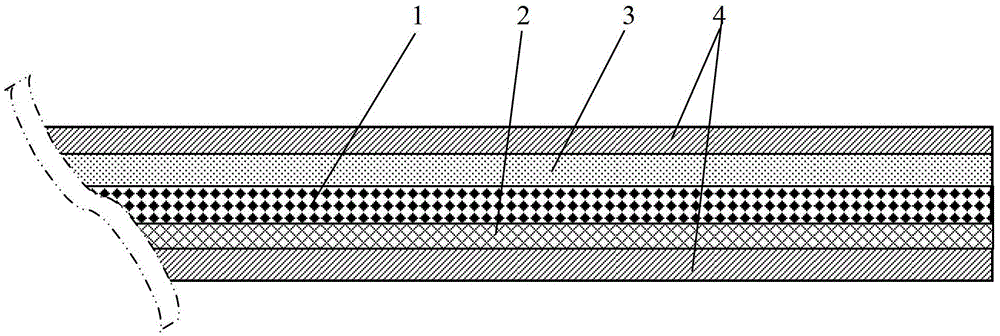

Image

Examples

Embodiment 1

[0046] Embodiment 1: Adopted on the surface of the locomotive cast iron engine case.

[0047] In this embodiment, the components and weight percentages of the metal aluminum salt coating agent of the present invention are: edible phosphoric acid 10-12%, aluminum oxide 4.5-5%, zinc oxide 1-2%, phosphatidic acid 1-1.5%, Manganese 1-2%, the balance of water.

[0048] The specific production method steps are as follows:

[0049] 1) First prepare the ingredients according to the ratio, and divide the remaining water into three equal parts;

[0050] 2) Prepare a low-pressure reaction kettle for the container, make the ambient temperature above 30-40°C, and pour the prepared edible phosphoric acid into it;

[0051] 3) Add alumina, then add a portion of water, stir until completely dissolved;

[0052] 4) Add zinc oxide, add a portion of water, and stir until completely dissolved;

[0053] 5) Add manganese, add a portion of water, and stir until completely dissolved;

[0054] 6) A...

Embodiment 2

[0057] Embodiment 2: Applied on the surface of the cast steel body of the locomotive.

[0058] In this embodiment, the components and percentages by weight of the metal aluminum salt coating agent of the present invention are: 18-20% of edible phosphoric acid, 5% of aluminum oxide, 2-4% of zinc oxide, 1-1.5% of phosphatidic acid, 1% of manganese -2%, water balance.

[0059] The specific production method steps are as in Example 1, the difference is that in step 7: use roller coating, brush coating or wiping coating, and keep the ambient temperature at 5°C-20°C to dry naturally, which forms a 25-28 micron film layer on the surface of the cast steel body .

[0060] The locomotive is assembled with this kind of cast steel body, which has good anti-corrosion effect.

Embodiment 3

[0061] Embodiment 3: Applied on the surface of profiles such as Q plates and angle steels.

[0062] In this embodiment, the components and weight percentages of the metal aluminum salt coating agent of the present invention are: edible phosphoric acid 20-25%, aluminum oxide 5-8%, nickel oxide 1-1.8%, zinc oxide 2-3%, phosphorus Esteric acid 1-1.5%, manganese 1-2%, water balance.

[0063] The specific production method steps are as follows:

[0064] 1) First prepare the ingredients according to the ratio, and divide the remaining water into four equal parts;

[0065] 2) Prepare a container so that the ambient temperature reaches above 30-40°C, and pour the prepared edible phosphoric acid into it;

[0066] 3) Add alumina, then add a portion of water, stir until completely dissolved;

[0067] 4) Add nickel oxide, add a portion of water, and stir until completely dissolved;

[0068] 5) Add zinc oxide directly, add a portion of water, and stir until completely dissolved;

[00...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com