Collagen composite peptide powder

A technology of compound peptide and bone collagen peptide, which is applied in the field of health food of collagen compound peptide powder, can solve the problems of insufficient development of yak bone nutritional components, small protein molecules, etc., and achieve rapid replenishment of physical strength, small molecular weight, The effect of relieving fatigue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

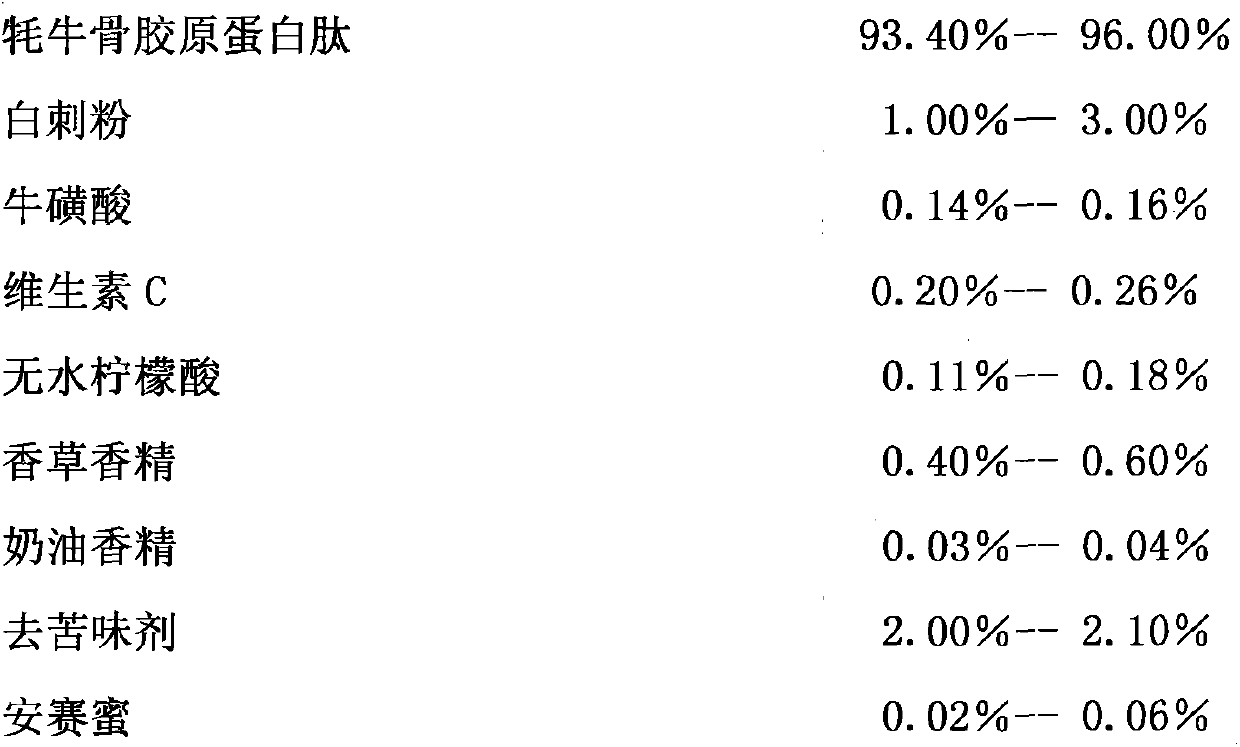

Embodiment 1

[0022] Embodiment 1: A kind of collagen compound peptide powder, its component and ratio are: 93.40 parts of yak bone collagen protein peptide, 3.00 parts of white thorn powder, 0.16 part of taurine, 0.26 part of vitamin C, 0.18 part of anhydrous citric acid 0.60 parts of vanilla flavor, 0.04 parts of cream flavor, 2.10 parts of bittering agent, 0.06 parts of acesulfame potassium, 0.20 parts of milk flavor,

[0023] The preparation method is as follows: (1) quality inspection, the main and auxiliary materials must meet the product quality standards; (2) weighing, accurately weigh the weight of the main and auxiliary materials; (3) mixing, the main and auxiliary materials according to the formula ratio are put into the mixer, and stirred evenly (4) sieving, passing through a 40-mesh vibrating sieve, and filtering; (5) filling, using a packaging machine to fill into bags; (6) boxing, subpackaging into boxes, adding desiccant, and sealing; (7) finished product Inspection, qualifi...

Embodiment 2

[0024] Embodiment 2: A kind of collagen compound peptide powder, its component and ratio are: 96.00 parts of yak bone collagen protein peptide, 1.00 parts of white thorn powder, 0.14 parts of taurine, 0.20 parts of vitamin C, 0.11 parts of anhydrous citric acid 0.40 parts of vanilla flavor, 0.03 parts of cream flavor, 2.00 parts of bittering agent, 0.02 parts of acesulfame potassium, 0.10 parts of milk flavor,

[0025] The preparation method is as follows: (1) quality inspection, the main and auxiliary materials must meet the product quality standards; (2) weighing, accurately weigh the weight of the main and auxiliary materials; (3) mixing, the main and auxiliary materials according to the formula ratio are put into the mixer, and stirred evenly (4) sieving, passing through a 40-mesh vibrating sieve, and filtering; (5) filling, using a packaging machine to fill into bags; (6) boxing, subpackaging into boxes, adding desiccant, and sealing; (7) finished product Inspection, qual...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com