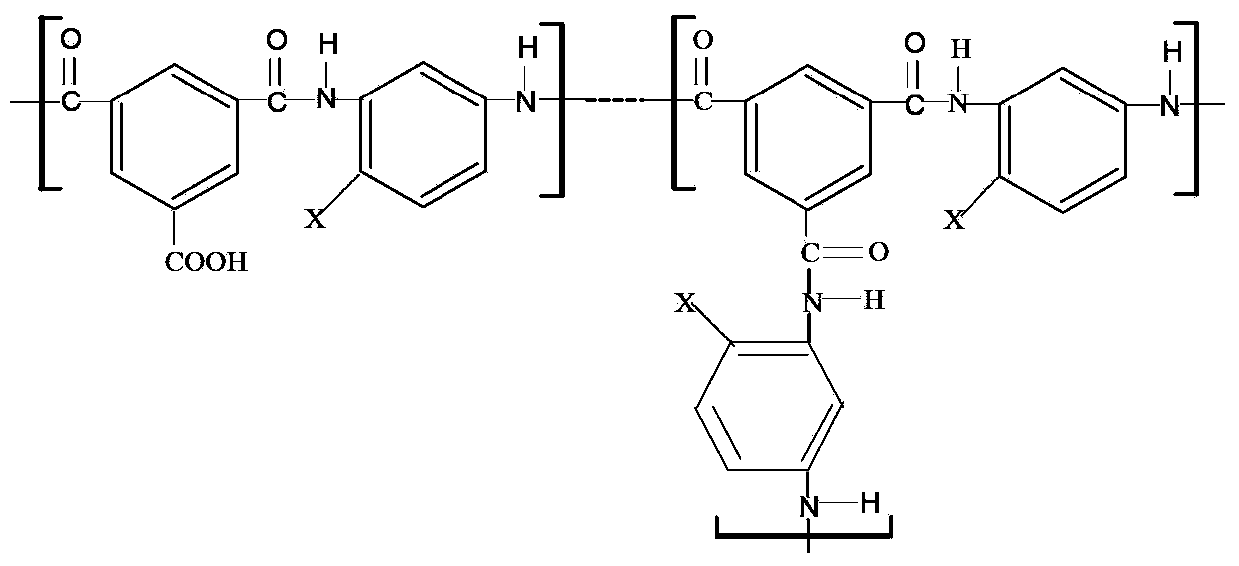

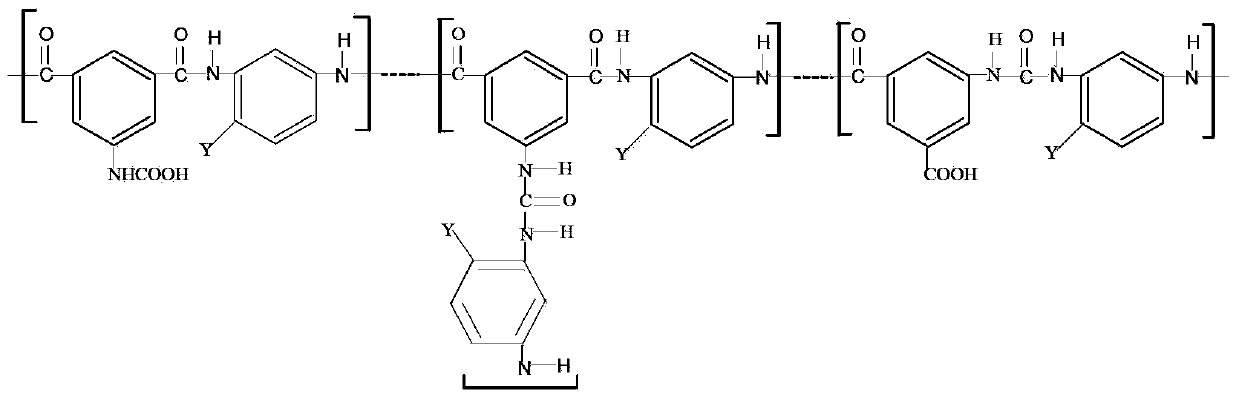

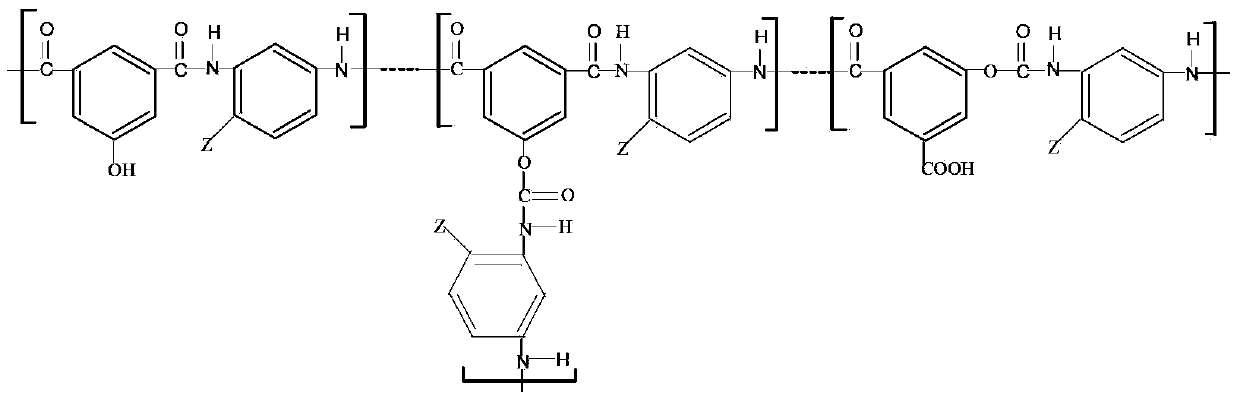

Composite reverse osmosis membrane with antibacterial function

A reverse osmosis composite membrane and functional technology, applied in the field of polymer composite membranes for water treatment, can solve the problems of membrane surface biochemical pollution, membrane fouling, and restrictions on the application of reverse osmosis technology, and achieve improved hydrophilicity, simple preparation methods, Improve the effect of antibacterial and anti-biofouling properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-8

[0053] Table 1: Performance of reverse osmosis composite membranes with different desalination layer materials

[0054]

[0055]

[0056] The above examples show that the reverse osmosis composite membrane with antibacterial function can be obtained by depositing silver chloride coating on the surface of the reverse osmosis composite membrane containing different polymer desalination layers through the solution alternate impregnation technique, and the separation performance is obviously better than that of ordinary reverse osmosis composite membrane. Permeate the composite membrane.

Embodiment 9-14

[0058] Table 2: Performance of reverse osmosis composite membranes with different inorganic antibacterial coating materials

[0059]

[0060] The above examples show that the reverse osmosis composite membrane with antibacterial function can be obtained by coating the surface of the reverse osmosis composite membrane with fully aromatic polyamide as the desalination layer by alternate solution impregnation technology, and the separation performance is better than Ordinary fully aromatic polyamide reverse osmosis composite membrane.

Embodiment 15-20

[0062] Table 3: Performance of reverse osmosis composite membranes with different thicknesses of inorganic antibacterial material layers

[0063]

[0064]

[0065] The above examples show that the reverse osmosis composite membrane with antibacterial function can be obtained by coating the surface of the reverse osmosis composite membrane with fully aromatic polyamide as the desalination layer by alternately impregnating the solution with different thicknesses of silver carbonate inorganic antibacterial materials. Membranes with coating material thickness less than 200nm have better separation performance.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com