Surface mineralized composite reverse osmosis membrane with high hydrophilicity

A reverse osmosis membrane, water-based technology, applied in semi-permeable membrane separation, general water supply saving, osmosis/dialysis water/sewage treatment and other directions, can solve the problems of increasing operating costs, restricting the popularization and application of polyamide composite reverse osmosis membranes, etc. To achieve the effects of improved surface hydrophilicity, good anti-pollution performance and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] The preparation of porous supporting membrane: prepare by conventional method, the present invention is to dissolve in the polar organic solvent with the UDEL PS3500LCD polysulfone of 12.5wt%, the water of 0.3wt% and the tensio-active agent of 0.1wt%, be coated with scraping on polyester After immersing in water to remove solvents and additives, a porous support membrane with a molecular weight cut off (MWCO) of about 100,000 is obtained. Wherein, the surfactant includes at least one of alkylphenol polyoxyethyl ester phosphate, sodium dodecyl sulfonate and alkylphenol polyoxyethyl ester phosphate; the polar organic solvent is N,N-dimethyl Acetamide, or N,N-dimethylformamide, or N-methylpyrrolidone, or a mixture thereof.

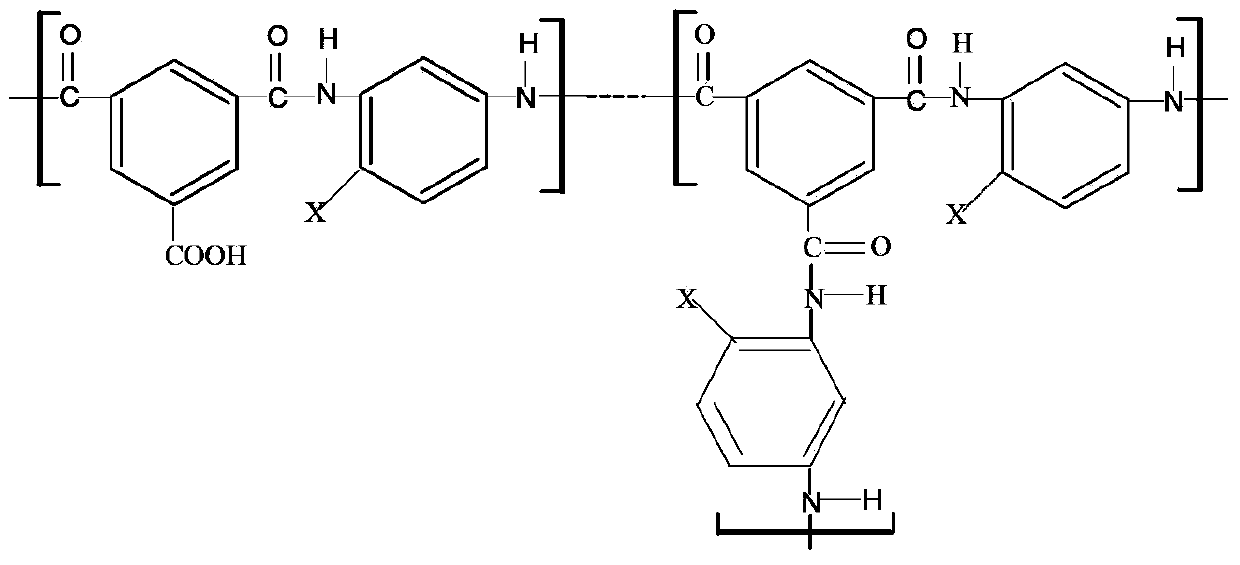

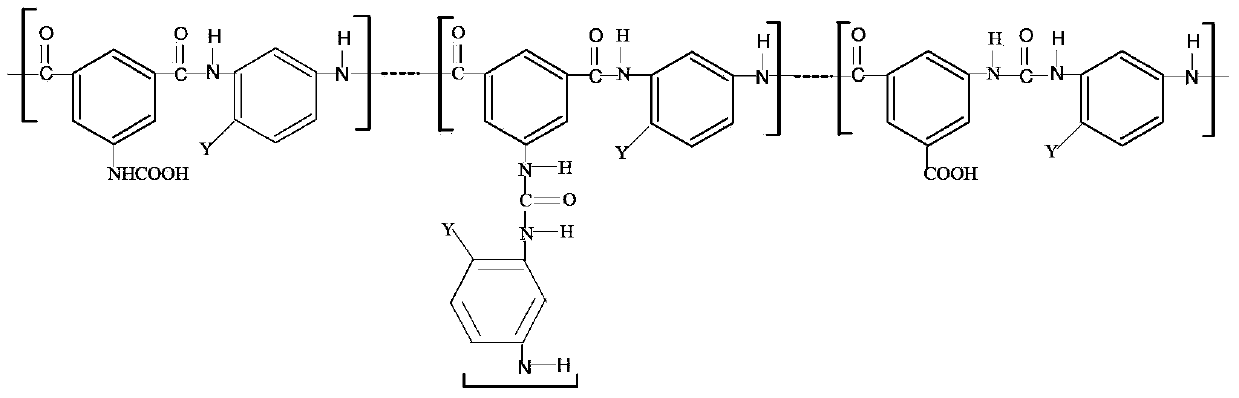

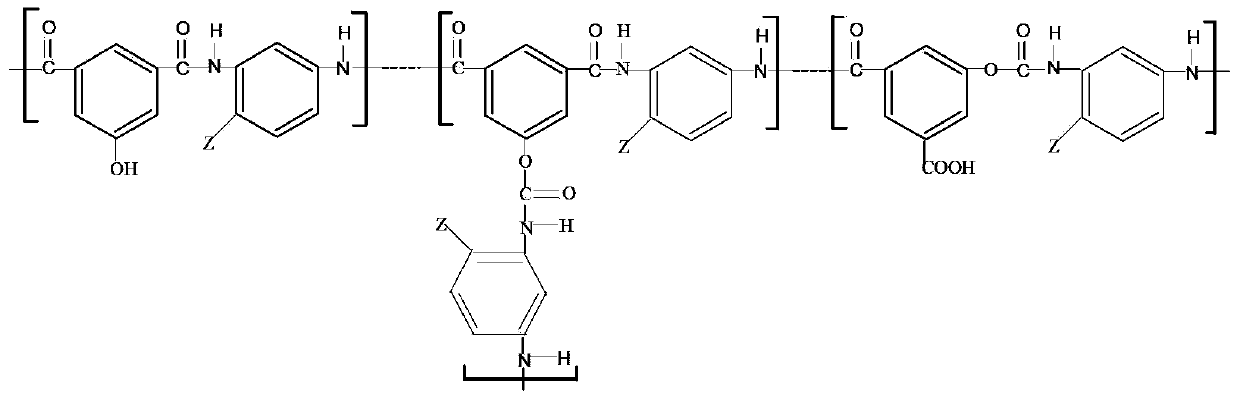

[0032] Preparation of polyamide polymer desalination layer: Coat the surface of wet polysulfone support membrane with polyamine solution, roll the surface of the support membrane with a rubber roller and squeeze it dry, and then coat the surface of the...

Embodiment 1-8

[0050]Table 1: Membrane performance of composite reverse osmosis membranes with different desalination layer materials after surface mineralization treatment

[0051]

[0052]

[0053] The above examples show that: the barium sulfate coating is deposited on the surface of the composite reverse osmosis membrane composed of porous polysulfone support membrane and different polyamide desalination layer materials through mineralization treatment, and the desalination rate of the composite reverse osmosis membrane obtained by the new structure is maintained. Unchanged or slightly improved, the hydrophilicity and water flux of the membrane surface are superior to the traditional composite reverse osmosis membrane composed of a porous support layer and a polymer desalination layer.

Embodiment 9-15

[0055] Table 2: Performance of composite reverse osmosis membranes with different mineralized layer thicknesses

[0056]

[0057]

[0058] The above examples show that: the surface of the composite reverse osmosis membrane composed of porous polysulfone support membrane and fully aromatic polyamide desalination layer is coated with barium sulfate coating through mineralization treatment, and the hydrophilicity of the composite reverse osmosis membrane of the new structure obtained is Both are superior to the traditional composite reverse osmosis membrane composed of a porous support layer and a polymer desalination layer, but an overly thick mineralized layer will lead to a decrease in the desalination rate and water flux of the composite reverse osmosis membrane, and the membrane with a coating material thickness of less than 150nm The salt rejection rate and water flux are better than those of composite reverse osmosis membranes with unmineralized surface.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com