Method for synthesizing slump-resistant naphthalene-based efficient water reducing agent

A technology of high-efficiency water reducer and synthesis method, which is applied in the preparation process of dispersants and oilfield chemicals, and the synthesis field of slump-preserving naphthalene-based high-efficiency water reducer, which can solve bleeding, loss of fluidity of fresh concrete, and late stage Rapid loss of fluidity and other issues, to achieve the effect of performance optimization and fluidity maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

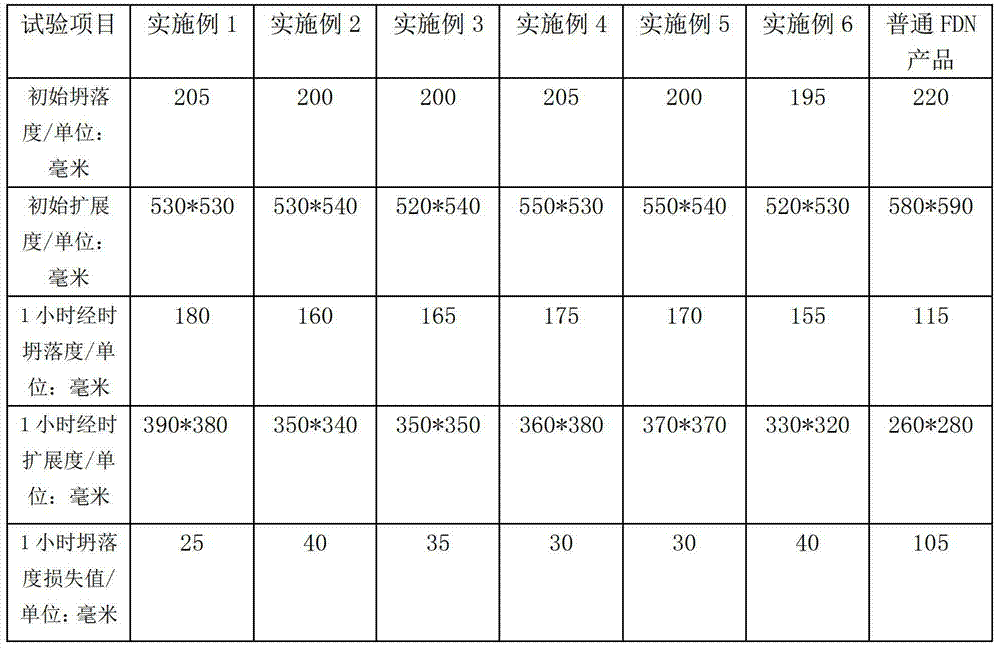

Examples

Embodiment 1

[0018] A synthetic method of a slump-preserving naphthalene series high-efficiency water reducer, the steps of which are as follows:

[0019] A. Add 100 kg of 95% industrial naphthalene into a glass-lined reactor, heat and melt to 135°C, add 110 kg of 98% industrial concentrated sulfuric acid, react at 163°C for 2.5 hours, and the acidity is 32.28% as measured by sampling;

[0020] B. Cool down to 122°C, add 32 kg of water, and hydrolyze for 0.5 hours;

[0021] C, be cooled to 95 ℃, add 58 kilograms of 37% industrial formaldehyde solution and carry out condensation reaction, condensation reaction temperature 116 ℃, time 4 hours, get naphthalenesulfonic acid formaldehyde condensate;

[0022] D. Cool down to 95°C, add 5.5 kg of isobutylamine and react with naphthalenesulfonic acid formaldehyde condensate for 1 hour, and the reaction temperature is 76°C;

[0023] E, add 32wt% sodium hydroxide aqueous solution, reactant is neutralized to pH value 6~7;

[0024] F. The liquid prod...

Embodiment 2

[0026] A synthetic method of a slump-preserving naphthalene series high-efficiency water reducer, the steps of which are as follows:

[0027] A. Add 100 kg of 95% industrial naphthalene into a glass-lined reactor, heat and melt to 145°C, add 110 kg of 98% industrial concentrated sulfuric acid, react at 158°C for 3 hours, and the acidity measured by sampling is 32.63%;

[0028] B. Cool down to 128°C, add 35 kg of water, and hydrolyze for 1.5 hours;

[0029] C, be cooled to 98 ℃, add 58 kilograms of 37% industrial formaldehyde solution and carry out condensation reaction, condensation reaction temperature 108 ℃, time 6 hours, get naphthalenesulfonic acid formaldehyde condensate;

[0030] D. Cool down to 78°C, add 5.5 kg of n-butylamine and react with naphthalenesulfonic acid formaldehyde condensate for 2 hours, and the reaction temperature is 76°C;

[0031] E, add 32wt% sodium hydroxide aqueous solution, reactant is neutralized to pH value 6~7;

[0032] F. The liquid product i...

Embodiment 3

[0034] A synthetic method of a slump-preserving naphthalene series high-efficiency water reducer, the steps of which are as follows:

[0035] A. Add 95 kg of 99% refined naphthalene into a glass-lined reactor, heat and melt to 135°C, add 120 kg of 98% industrial concentrated sulfuric acid, react at 162°C for 2.5 hours, and the acidity measured by sampling is 33.26%;

[0036] B. Cool down to 128°C, add 51 kg of water, and hydrolyze for 1.5 hours;

[0037] C, be cooled to 98 ℃, add 58 kilograms of 37% industrial formaldehyde solution and carry out condensation reaction, condensation reaction temperature 118 ℃, time 6 hours, get naphthalenesulfonic acid formaldehyde condensate;

[0038] D. Cool down to 85°C, add 16.5 kg of sec-butylamine and react with naphthalenesulfonic acid formaldehyde condensate for 2 hours, and the reaction temperature is 85°C;

[0039] E, add 32wt% sodium hydroxide aqueous solution, reactant is neutralized to pH value 6~7;

[0040] F. The liquid product ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com