Preparation method of airgel modified synthetic fiber and prepared synthetic fiber

A synthetic fiber and airgel technology, applied in the direction of one-component polyolefin rayon, one-component polyamide rayon, one-component polyester rayon, etc., to achieve improved heat insulation performance and good ventilation Sexuality and sweat absorption ability, the effect of reducing thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

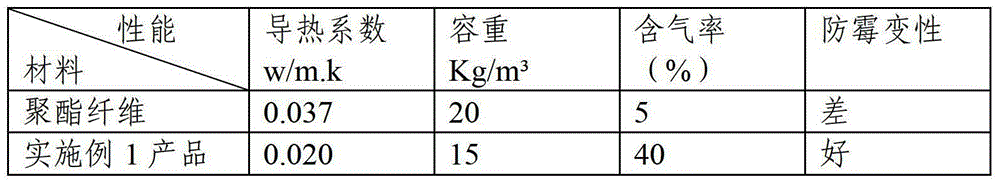

[0019] PET (polyethylene terephthalate, DuPont FR530), 138 kg, airgel powder is mcf-40 (Shaanxi Mengchuang Nano New Material Co., Ltd., thermal conductivity 0.01w / m.k, density 40kg / m 3 ) 4 kg, placed in a mixing device with screw extrusion and heated to 250 ° C to form a uniform melt and make a masterbatch; through the spinneret hole of the spinning machine (Longkou Huarui Machinery Factory, Longkou City), The spinneret hole diameter is 0.25 mm. The sprayed melt stream is cooled and solidified into filaments by the cooling airflow, forming airgel-modified synthetic fibers. Its thermal conductivity is measured to be 0.02w / m.k, which is 0.017m / m.k lower than that of traditional polyester fiber spinning cotton (0.037w / m.k). The bulk density and other performance parameters are shown in Table 1.

[0020] Table 1: Product performance of embodiment 1

[0021]

Embodiment 2

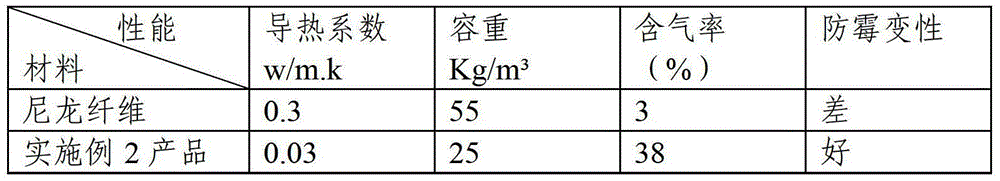

[0023] PA (polyamide No. 600, Shanghai Haohua Chemical Co., Ltd.) 115 kg, mcf-40 airgel powder 4 kg, placed in a mixer with screw extrusion and heated to 250 ° C to form a uniform melt, Through the spinneret hole, the diameter of the spinneret hole is 0.25 mm. The sprayed melt stream is cooled and solidified by the cooling airflow to form filaments to form airgel modified polyester fibers. The measured thermal conductivity is 0.03w / m.k, which is 0.017m / m.k lower than that of traditional synthetic fiber spinning cotton (0.83w / m.k); see Table 2 for bulk density and other performance parameters.

[0024] Table 2: Product performance of embodiment 2

[0025]

Embodiment 3

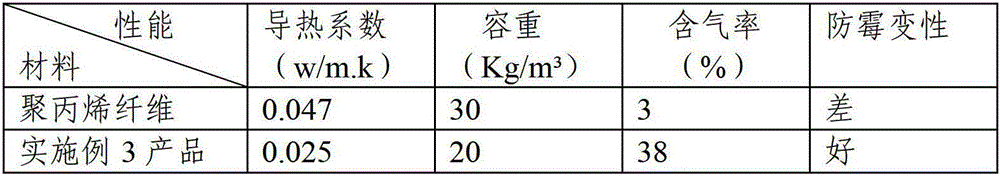

[0027] 95 kg of PP (polypropylene, Changzhou Chixin Plastic Industry Co., Ltd.), 4 kg of mcf-40 airgel powder, placed in a mixer with screw extrusion and heated to 180 ° C to form a uniform melt, Through the spinneret hole, the diameter of the spinneret hole is 0.30 mm. The sprayed melt stream is cooled and solidified into filaments by the cooling airflow, forming airgel-modified synthetic fibers. The measured thermal conductivity is 0.025w / m.k, which is 0.017m / m.k lower than that of traditional polyester fiber spun cotton (0.047w / m.k); see Table 3 for bulk density and other performance parameters.

[0028] Table 3: Product performance of embodiment 3

[0029]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com