Preparation method of graphene fiber

A technology of graphene fiber and graphene gel, which is applied in the fields of fiber chemical characteristics, textiles and papermaking, rayon chemical post-treatment, etc., can solve the problems of complex graphene fiber processing technology, long production cycle and high equipment requirements, and achieve Ease of industrial production, low equipment requirements, and simple preparation methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Weigh 300 mg of graphite oxide, add 10 g of distilled water, ultrasonicate for 2 h, add 1 g of sodium deoxycholate, stir magnetically at a speed of 600 rpm for 24 h, and prepare sodium deoxycholate / graphene oxide gel. Use a syringe pump to extrude the gel into a watch glass containing absolute ethanol at a speed of 1 mL / min, and replace the absolute ethanol 10 times in time. After washing for 3 hours, suck out the absolute ethanol until it evaporates completely, and obtain the oxidized gel after 2 hours. Graphene fibers. The prepared graphene oxide fibers were added with hydroiodic acid for reduction for 3 h to obtain graphene fibers. Wash 5 times with ultrapure water, let it stand for 6 hours to obtain hydrated graphene fibers, and dry again for 2 hours to obtain graphene fibers.

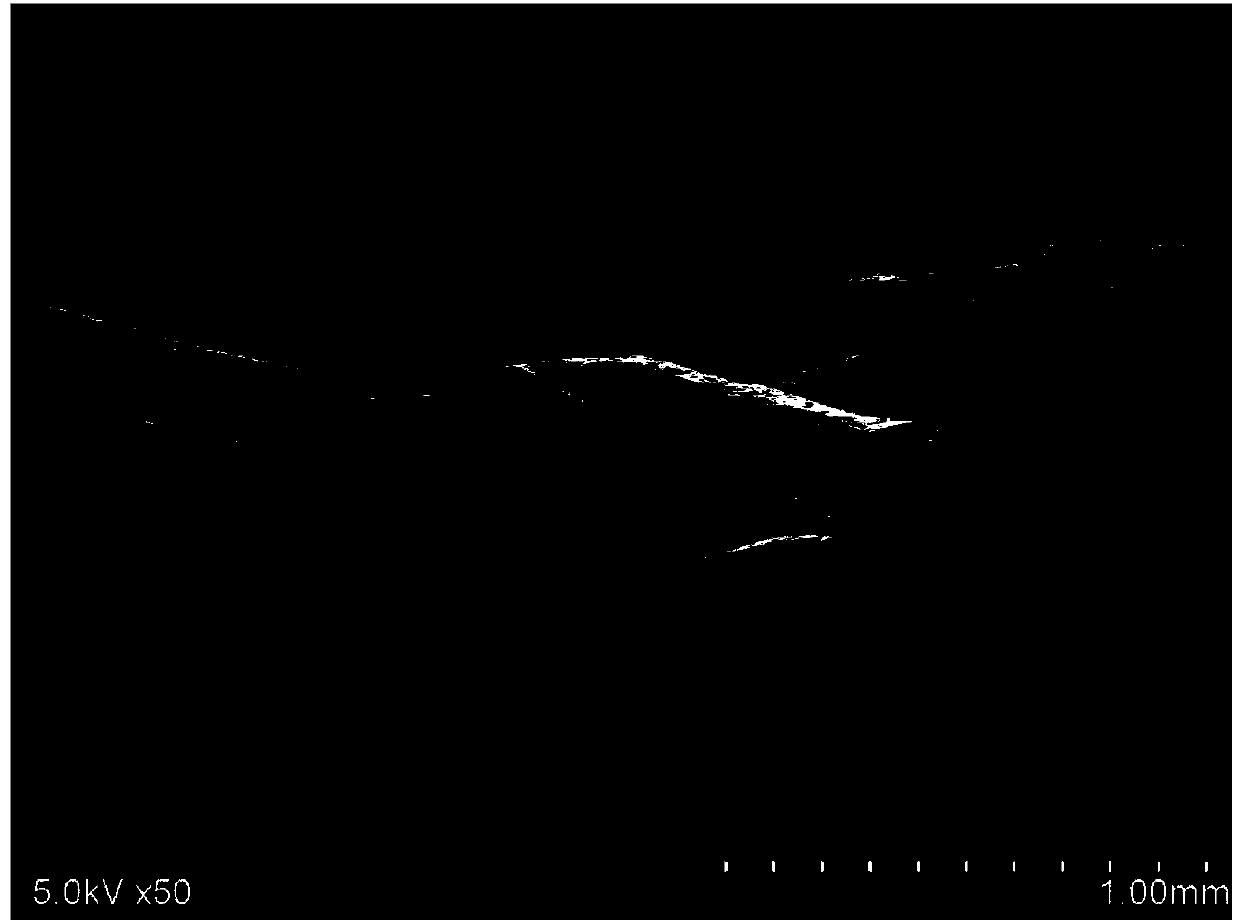

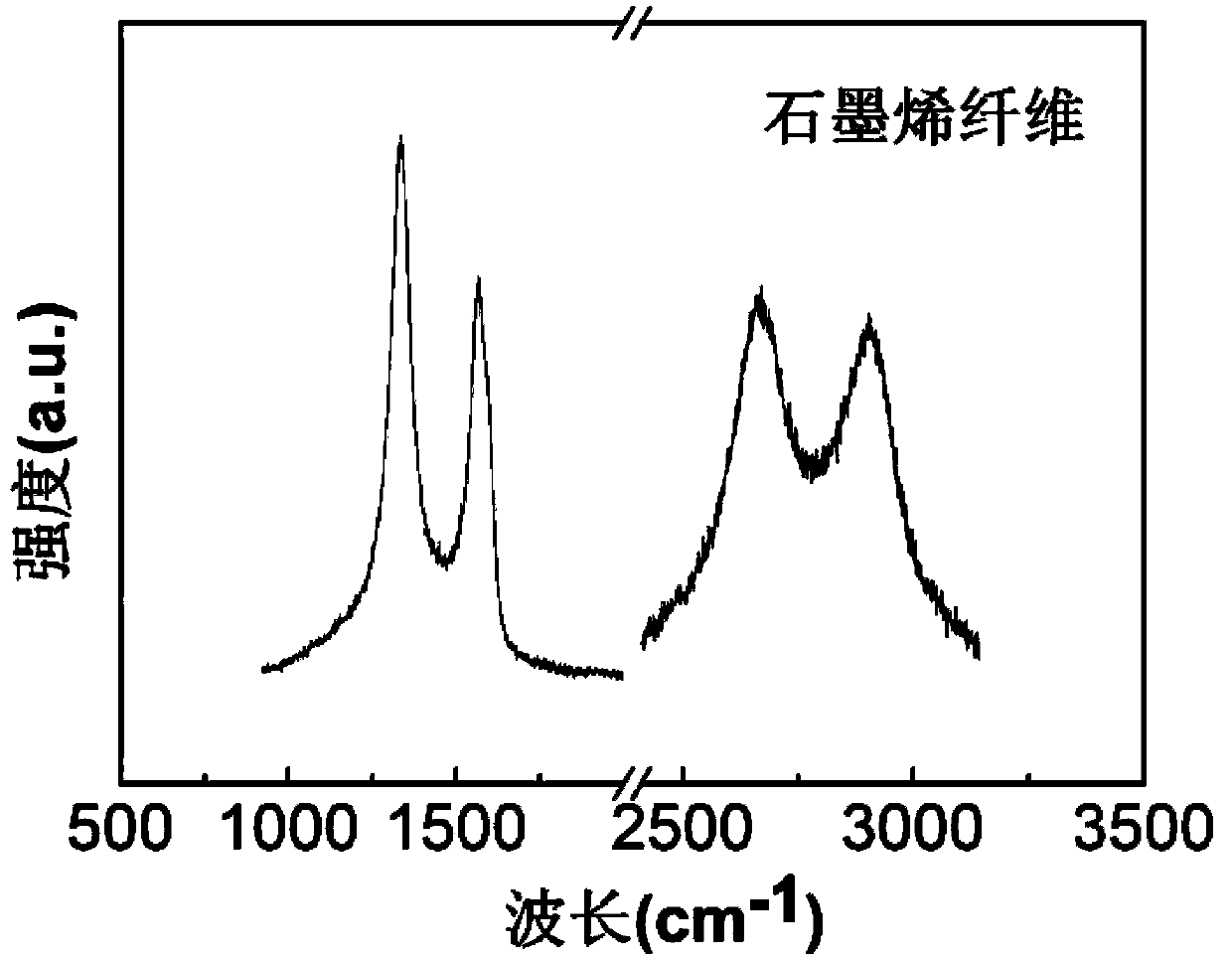

[0025] The electrical conductivity of the graphene fiber measured by the four-probe method is 500 S / m. like figure 1 In order to obtain macroscopic graphene fibers with high aspect ratio...

Embodiment 2

[0027] Weigh 100 mg of graphite oxide, add 10 g of distilled water, ultrasonicate for 1 h, add 4 g of sodium deoxycholate, stir magnetically at a speed of 300 rpm for 20 h, and prepare sodium deoxycholate / graphene oxide gel. Use a syringe pump to extrude the gel into a watch glass containing absolute ethanol at a speed of 0.6mL / min, and replace the absolute ethanol 8 times in time. After washing for 4 hours, suck out the absolute ethanol and wait for its evaporation to be obtained after 1 hour. Graphene oxide fibers. The prepared graphene oxide fibers were added with hydroiodic acid for reduction for 2 h to obtain graphene fibers. Wash 3 times with ultrapure water, let it stand for 4 hours to obtain graphene fibers containing water, and dry again for 1 hour to obtain graphene fibers. The electrical conductivity of the graphene fiber measured by the four-probe method is 200 S / m.

Embodiment 3

[0029] Weigh 400 mg of graphite oxide, add 10 g of distilled water, ultrasonicate for 1.5 h, add 1 g of sodium deoxycholate, stir magnetically at a speed of 500 rpm for 22 h, and prepare sodium deoxycholate / graphene oxide gel. Use a syringe pump to extrude the gel into a watch glass containing absolute ethanol at a speed of 0.8mL / min, and replace the absolute ethanol 5 times in time. After washing for 3.5 hours, suck out the absolute ethanol and wait for its evaporation to complete. Afterwards, graphene oxide fibers are obtained. The prepared graphene oxide fibers were added with hydroiodic acid for reduction for 2.5 h to obtain graphene fibers. Wash 4 times with ultrapure water, let stand for 5 hours to obtain graphene fibers containing water, and dry again for 1.5 hours to obtain graphene fibers. The electrical conductivity of the graphene fiber measured by the four-probe method is 400 S / m.

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com