Low-swinging carbon fiber photoelectric composite overhead conductor

A photoelectric composite and overhead wire technology, which is applied in the direction of circuits, power cables, electrical components, etc., can solve the problems of inability to realize communication functions, poor wind resistance of wires, and large galloping range, and achieve good softness and improved tensile strength. , The effect of reducing the lift coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

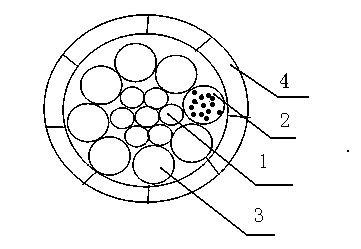

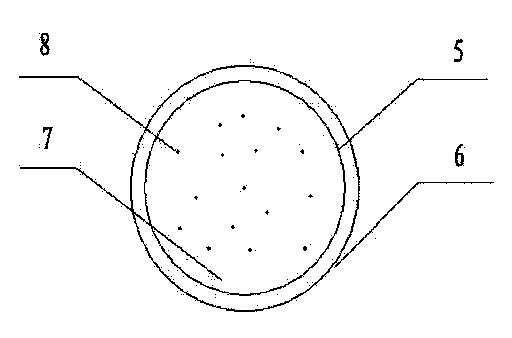

[0022] Such as figure 1 As shown, a low galloping carbon fiber photoelectric composite overhead wire, from the inside to the outside, sequentially includes a carbon fiber bearing member 1 twisted by 7 carbon fibers, at least one stainless steel optical unit 2 and several duralumin round wires 3 twisted The outer layer 4 of the duralumin-shaped wire composed of a number of trapezoidal duralumin-shaped wires that cooperate with each other constitutes a layered photoelectric composite structure adjacent to the inner layer; the carbon fiber load-bearing member 1 is a composite ultra-high-strength core wire, including longitudinally extending The main core of high-performance carbon fiber bundles, high-strength basalt fiber bundles, and high-strength S-glass fiber bundles that are continuously wound around the main core in a spiral shape, and the consolidation of high-performance carbon fiber bundles, high-strength basalt fiber bundles, and high-strength S-glass fiber bundles modif...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com