a bi 2 the se 3 Silicon Schottky junction with thin film as contact layer and preparation method

A Schottky junction and contact layer technology, which is applied in the direction of electrical components, circuits, semiconductor devices, etc., can solve the problems of unsuitability for large-scale production, deterioration of silicon Schottky junction characteristics, and unguaranteed quality of heterojunction interfaces and other problems, to achieve excellent optical and electrical properties, reduce Si surface state density, and ideal characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

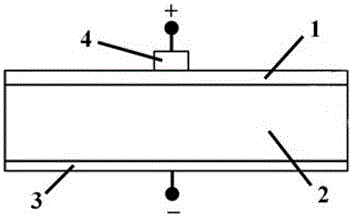

[0030] like figure 1 As shown, the present embodiment includes n-type Si substrate 2, the resistivity of Si substrate 2 is 0.001Ω·cm, and the top of Si substrate 2 is provided with Bi 2 Se 3 Schottky contact layer 1, Bi 2 Se 3 The thickness of Schottky contact layer 1 is 5nm, and the bottom of Si substrate 2 is provided with ohmic contact back electrode 3, Bi 2 Se 3 The Schottky contact layer 1 is provided with an ohmic contact electrode 4 made of Al with a thickness of 20nm, Bi 2 Se 3 An adhesive layer is provided between the Schottky contact layer 1 and the ohmic contact electrode 4, and the adhesive layer is made of Cr.

[0031] Preferably, the Si substrate 2 in this embodiment is a (111)-oriented single crystal.

[0032] A Bi 2 Se 3 A method for preparing a silicon Schottky junction with a thin film as a contact layer, comprising the following steps:

[0033] (a) After the Si substrate with the crystal orientation of (111) is cleaned by RCA chemical cleaning meth...

Embodiment 2

[0040] like figure 1 As shown, the present embodiment includes a p-type Si substrate 2, the resistivity of the Si substrate 2 is 10Ω·cm, and the top of the Si substrate 2 is provided with a thickness of 27.5nm. 2 Se 3 Schottky contact layer 1, the bottom of Si substrate 2 is provided with ohmic contact back electrode 3, Bi 2 Se 3 The Schottky contact layer 1 is provided with an ohmic contact electrode 4 made of Ag and having a thickness of 110 nm, Bi 2 Se 3 An adhesive layer is provided between the Schottky contact layer 1 and the ohmic contact electrode 4, and the adhesive layer is made of Ti.

[0041] Preferably, the Si substrate 2 in this embodiment is a (111)-oriented single crystal.

[0042] A Bi 2 Se 3 A method for preparing a silicon Schottky junction with a thin film as a contact layer, comprising the following steps:

[0043] (a) After the Si substrate with the crystal orientation of (111) is cleaned by RCA chemical cleaning method, the chemical passivation pr...

Embodiment 3

[0050] like figure 1 As shown, the present embodiment includes a type that is close to the high-resistance n-Si substrate 2 of intrinsic conductance, the resistivity of Si substrate 2 is 5000Ω·cm, and the top of Si substrate 2 is provided with the Bi that thickness is 50nm 2 Se 3Schottky contact layer 1, the bottom of Si substrate 2 is provided with ohmic contact back electrode 3, Bi 2 Se 3 The Schottky contact layer 1 is provided with an ohmic contact electrode 4 made of Au with a thickness of 200nm, Bi 2 Se 3 An adhesive layer is provided between the Schottky contact layer 1 and the ohmic contact electrode 4, and the adhesive layer is made of Cr.

[0051] Preferably, the Si substrate 2 in this embodiment is a (111)-oriented single crystal.

[0052] A Bi 2 Se 3 A method for preparing a silicon Schottky junction with a thin film as a contact layer, comprising the following steps:

[0053] (a) After the Si substrate with the crystal orientation of (111) is cleaned by RC...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com