High-efficiency heterojunction monocrystalline silicon thin film solar cell

A technology of solar cells and amorphous silicon thin films, applied in circuits, photovoltaic power generation, electrical components, etc., can solve problems such as high energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

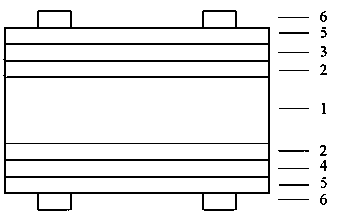

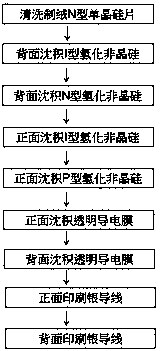

[0004] The structure of the present invention is hereby described as attached figure 1 , detailed below: See figure 2 , is a schematic block diagram of the action flow of the present invention. The process is to first deposit an I-type hydrogenated amorphous silicon film (2) and an N-type hydrogenated amorphous silicon film (4 ), and then turn the entire silicon wafer over, deposit I-type hydrogenated amorphous silicon film (2) and P-type hydrogenated amorphous silicon film (3) sequentially on the front, and then use magnetron sputtering or reactive The physical vapor deposition equipment first deposits a transparent conductive film (5) on a P-type amorphous silicon film (3), then deposits a transparent conductive film (5) on an N-type amorphous silicon film (4), and finally uses Silver wires (6) are laid on the front and back sides by screen printing, and the high-efficiency heterojunction monocrystalline silicon thin film solar cell is completed. The hydrogenated amorpho...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com