High-efficiency expanded compound feed for dace and preparation method thereof

A technology for extruding compound feed and dace, which is applied in the directions of animal feed, animal feed, application, etc., can solve the problems of short growth period of dace, difficulty in obtaining feed raw materials, and high bait coefficient, so as to improve immunity and disease resistance. , the effect of increasing the growth rate of dace and reducing the coefficient of feed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

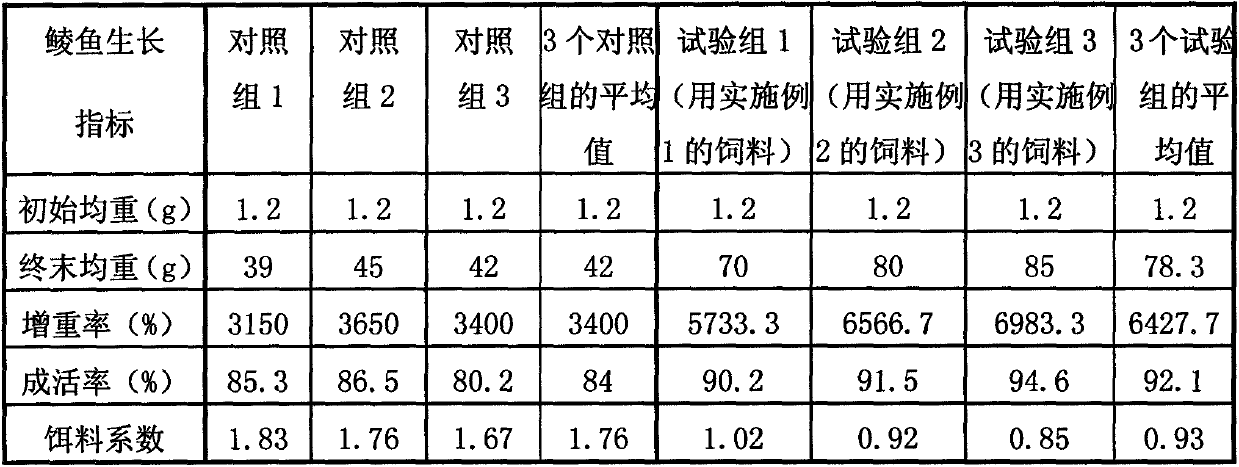

Examples

Embodiment 1

[0022] Prepare high-efficiency dace extruded compound feed according to the weight percentages of the following components:

[0023] Barley Bran 10%, Sargassum Powder 10%, Kelp Powder 8%, Shrimp Powder 15%, Shrimp Shell Powder 5%, Soy Protein Isolate 6%, Coconut Meal 10%, Palm Meal 10%, Corn 10%, Flour 8.5% , calcium dihydrogen phosphate 2%, palm oil 2%, herbivorous fish premix 2%, complex amino acid mixture 1.0%, butyrin 0.5%.

[0024] The preparation steps of the high-efficiency mud carp compound feed:

[0025] 1) Weigh each component raw material according to the above ratio, mix and stir evenly;

[0026] 2) The component raw materials after the mixing and stirring described in step 1) are further pulverized by an ultrafine pulverizer until they can pass through an 80-mesh sieve;

[0027] 3) All the pulverized materials are moved into the modulator, according to 18% of the weight of the raw materials, the water vapor at 100°C is passed through for modulation for 1 minute,...

Embodiment 2

[0031] Prepare high-efficiency dace extruded compound feed according to the weight percentages of the following components:

[0032] Barley Bran 20%, Sargassum Powder 10%, Kelp Powder 10%, Shrimp Powder 10%, Shrimp Shell Powder 6%, Soy Protein Isolate 5%, Coconut Meal 10%, Palm Meal 8%, Corn 6.2%, Flour 10% , calcium dihydrogen phosphate 1.5%, palm oil 1%, herbivorous fish premix 1%, compound amino acid mixture 1.0%, butyrin 0.3%.

[0033] The preparation steps of this mud carp compound feed:

[0034] 1) Weigh each component raw material according to the above ratio, mix and stir evenly;

[0035] 2) The component raw materials after mixing and stirring described in step 1) are further pulverized by an ultrafine pulverizer until they can pass through a 70-mesh sieve;

[0036] 3) Move all the pulverized materials into the modulator, pass 20% of the weight of the raw materials into the steam at 100°C for 1.5 minutes, and make the raw materials enter the extrusion extruder granu...

Embodiment 3

[0040] Prepare high-efficiency dace extruded compound feed according to the weight percentages of the following components:

[0041] Barley Bran 15%, Sargassum Powder 15%, Kelp Powder 6%, Shrimp Powder 15%, Shrimp Shell Powder 5%, Soy Protein Isolate 7%, Coconut Meal 5%, Palm Meal 5%, Corn 10%, Flour 9.5% , calcium dihydrogen phosphate 2%, palm oil 2%, herbivorous fish premix 2%, complex amino acid mixture 1.0%, butyrin 0.5%.

[0042] The preparation steps of this mud carp compound feed:

[0043] 1) Weigh each component raw material according to the above ratio, mix and stir evenly;

[0044] 2) The component raw materials after the mixing and stirring described in step 1) are further pulverized by an ultrafine pulverizer until they can pass through a 60-mesh sieve;

[0045] 3) All the pulverized materials are moved into the modulator, and 19% of the weight of the raw materials is passed into the steam at 105°C for 2 minutes to make the raw materials enter the extruding extru...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com